Hi guys,

I have a Fiat 500 1.3 Multijet. I've had the car going onto 3 years and it's around 103k on the clock. I normally carry out my own servicing and small repairs. Yesterday I when I popped the bonnet, I noticed a strong smell of diesel. After further inspection, I noticed that there was an amount of diesel on the gearbox and some on the floor.

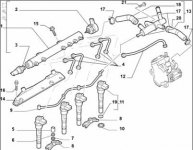

I've done some research and the high-pressure pump is known for its seals wearing and then slowly leaking diesel. I'm almost certain it's coming from that area. Just wanted some advice, if anyone on here has carried out the Fuel pressure pump replacement seals job? I've seen a few videos on Youtube, it seems pretty straight forward. As the seal kit is £24 and a recon pump is around £160.

I've recently just spent £800 on a gearbox replacement and can't afford to take much more of a hit on the vehicle, which is why I'm going to try the repair myself.

Anyone got any advice?

I have a Fiat 500 1.3 Multijet. I've had the car going onto 3 years and it's around 103k on the clock. I normally carry out my own servicing and small repairs. Yesterday I when I popped the bonnet, I noticed a strong smell of diesel. After further inspection, I noticed that there was an amount of diesel on the gearbox and some on the floor.

I've done some research and the high-pressure pump is known for its seals wearing and then slowly leaking diesel. I'm almost certain it's coming from that area. Just wanted some advice, if anyone on here has carried out the Fuel pressure pump replacement seals job? I've seen a few videos on Youtube, it seems pretty straight forward. As the seal kit is £24 and a recon pump is around £160.

I've recently just spent £800 on a gearbox replacement and can't afford to take much more of a hit on the vehicle, which is why I'm going to try the repair myself.

Anyone got any advice?