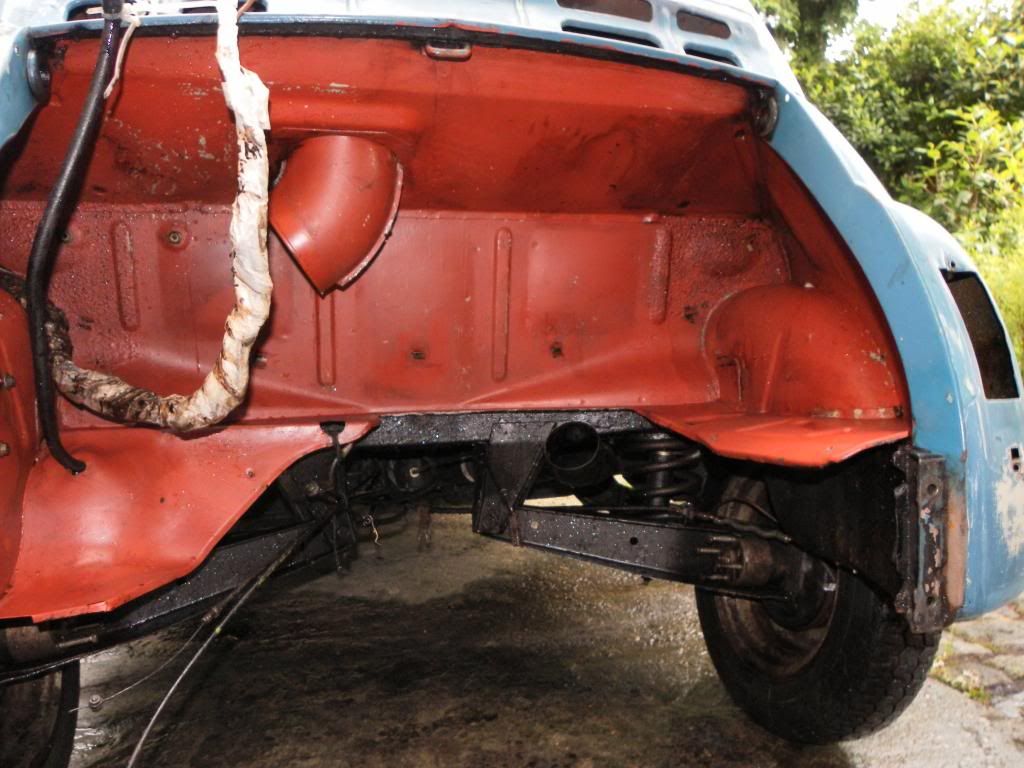

I just took a picture on my car and it doesn't make any difference if the car is LHD or RHD the wipers are mounted in the same place. As Peter said it looks like different to mine.

It seems Fiat changed the mechanism design when the L came out and as my car is an F it won't be much good to you but the one on the F just slips out with ease as it is much thinner.

Is that white bit pressed up against the cowling made of plastic?

It seems Fiat changed the mechanism design when the L came out and as my car is an F it won't be much good to you but the one on the F just slips out with ease as it is much thinner.

Is that white bit pressed up against the cowling made of plastic?