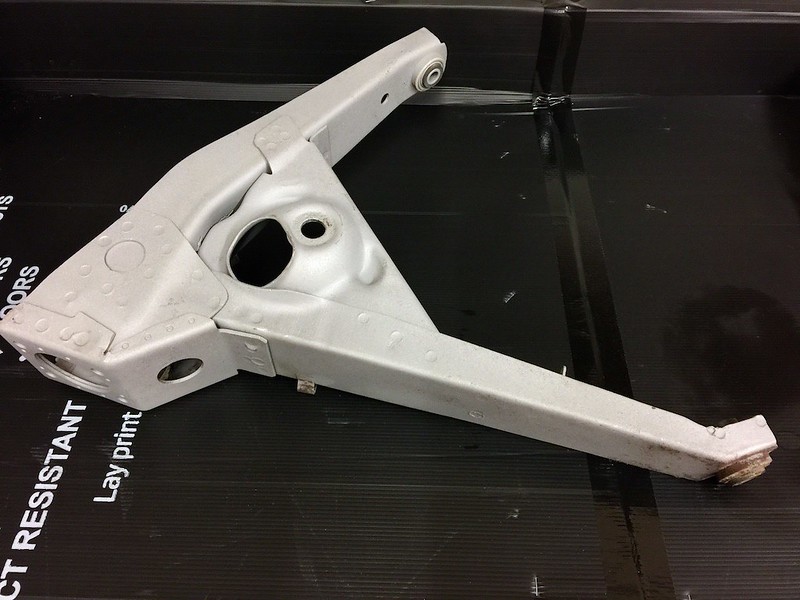

The big news (for Buzz at least) is he’s had a day trip out to the blasters. I decided this was the best course of action, because with the time/money invested in this resto I wanted to be fully aware of what was lurking beneath the paint and see the condition of the shell. So the decision was made to take the car to Soda Blasting Limited in Wolverhampton. They did the shell, doors, engine cover, rear beam, trailing arms and 5 wheels.

With the help of some neighbors, we loaded Buzz onto the back of my dad’s low-loader and took him down the M6 to Wolverhampton. This is easily the fastest he’s ever been. :slayer:

This is the last time Buzz will be wearing red!

These pics were sent to me by the guys doing the blasting. In the booth.

Last Saturday we went to pick him up, he looked a little…different!

We loaded him back onto the truck and trundled home.

One advantage of having a fun little car like this is that there’s no shortage of very interested neighbours who want to know what we’re upto, so within a few minutes of being home we had a team of 6 to carefully take him off the truck and put him back on the wooden dolly I’d made earlier.

This marked something of a turning point in the project, as it’s almost the end of all the “dirty” grinding jobs, so I took the opportunity to give the garage a much needed clean and put some protective sheeting on the floor, as the next step will be spraying.

More to come!

With the help of some neighbors, we loaded Buzz onto the back of my dad’s low-loader and took him down the M6 to Wolverhampton. This is easily the fastest he’s ever been. :slayer:

This is the last time Buzz will be wearing red!

These pics were sent to me by the guys doing the blasting. In the booth.

Last Saturday we went to pick him up, he looked a little…different!

We loaded him back onto the truck and trundled home.

One advantage of having a fun little car like this is that there’s no shortage of very interested neighbours who want to know what we’re upto, so within a few minutes of being home we had a team of 6 to carefully take him off the truck and put him back on the wooden dolly I’d made earlier.

This marked something of a turning point in the project, as it’s almost the end of all the “dirty” grinding jobs, so I took the opportunity to give the garage a much needed clean and put some protective sheeting on the floor, as the next step will be spraying.

More to come!