You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical HI Need help with wiring 500 L

- Thread starter phoenix1

- Start date

Currently reading:

Technical HI Need help with wiring 500 L

All though I am 67 now I still get bored.My wife says the net car will have to be blue.

My user name is Phoenix( yes I know it is spelt wrong) because up till about 10 years ago I was still rallying .But my car caught fire and we just got out in time.neither the on board extinguishers and the marshals own fail to put it out.It was probably the turbo ,it took the local fire brigade to finally put it out .(25 minutes later) so nothing left.Even the head and top of the gearbox melted so scrap one escort turbo.

My user name is Phoenix( yes I know it is spelt wrong) because up till about 10 years ago I was still rallying .But my car caught fire and we just got out in time.neither the on board extinguishers and the marshals own fail to put it out.It was probably the turbo ,it took the local fire brigade to finally put it out .(25 minutes later) so nothing left.Even the head and top of the gearbox melted so scrap one escort turbo.

Hi does anyone out there knows where I can get a pinion for a RHD steering box

or a refurbished one.I have about 2in of play at wheel .Not good

The other thing I could do is a rack conversion.Does anyone know what actual rack to use.

Thanks

or a refurbished one.I have about 2in of play at wheel .Not good

The other thing I could do is a rack conversion.Does anyone know what actual rack to use.

Thanks

IanEmery

Established member

Hi does anyone out there knows where I can get a pinion for a RHD steering box

or a refurbished one.I have about 2in of play at wheel .Not good

The other thing I could do is a rack conversion.Does anyone know what actual rack to use.

Thanks

Hi,

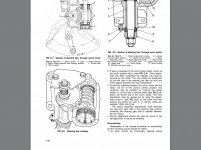

On the steering box you will see a large castellated nut that adjusts the mesh of the gears. The nut can be very tight and you may need to make a special tool to adjust it. I've copied part of a page from the workshop manual to show what to look for.

Hope this helps you.

Attachments

Thanks for that .I have adjusted the other one ,but if you take the play out

its much to tight.

Is that the one described as "the eccentric bush"?

It sounds like there are three basic adjustments... the worm between its bearings, the centralisation of the teeth of the two components in mesh and the depth of contact of the teeth.

Could it be that each affects the other?

Even my 80 year old Austin had more positive steering than that. Do you have any idea of the mileage of your car? I think it would have to be a fair old distance even to wear like that. I wouldn't give up on it yet. Although I admit I didn't even have to replace the seals on mine so maybe I'm a bit optimistic.

Hi according to the speedo it has done 37000.

I think these boxes wear because they leak oil,even after changing

all the gaskets etc mine still leaked.

When I get it repaired I am thinking of putting some type of grease

in rather than oil.I will try it with oil first to check if it still leaks.

I have managed to get the engine and box leak free so just this now.

Thanks

I think these boxes wear because they leak oil,even after changing

all the gaskets etc mine still leaked.

When I get it repaired I am thinking of putting some type of grease

in rather than oil.I will try it with oil first to check if it still leaks.

I have managed to get the engine and box leak free so just this now.

Thanks

I haven't needed to do mine and is doesn't leak at all from new.Hi according to the speedo it has done 37000.

But the leaky seals might be due to things not running perfectly in alignment.

Looking at the purposes of the adjustments available I wouldfirst take up the slack on the worm gear, centralise the mesh of the teeth of the pinion and then get teh optimum depth.The castellated ring thing on its own wouldn't take out all the free play.

Hi using that nut (which I found an angle grinder spanner did the trick )

I think by adjusting them together to find the optimum settings it may have worked. Took about an hour to do but well worth it.

Took about an hour to do but well worth it.

It is now in the vice at the angle it fits at with a piece of tissue underneath

to see if it oil tight.If it is not I will do as the last post use a thinned down

grease.

A big thanks to all for the help. :worship: Bryan

Bryan

I think by adjusting them together to find the optimum settings it may have worked.

It is now in the vice at the angle it fits at with a piece of tissue underneath

to see if it oil tight.If it is not I will do as the last post use a thinned down

grease.

A big thanks to all for the help. :worship:

Hi.I have the alternator on the bench and when connecting the green (with a bulb

to the alternator.The bulb lights,but no feeling of resistance.

When I connect 12v to the alternator it energies the coil in it and you get the resistance to turn.Does this mean you need a certain wattage of bulb.

On another topic stood the steering box for four days at the angle fitted and NO leaks.Yahoo

By the way when I changed the clutch assembly ,to the new thrust bearing the new one was about13mm taller and the lever arm was at the correct position.

I don't know why. Thanks Bryan

to the alternator.The bulb lights,but no feeling of resistance.

When I connect 12v to the alternator it energies the coil in it and you get the resistance to turn.Does this mean you need a certain wattage of bulb.

On another topic stood the steering box for four days at the angle fitted and NO leaks.Yahoo

By the way when I changed the clutch assembly ,to the new thrust bearing the new one was about13mm taller and the lever arm was at the correct position.

I don't know why. Thanks Bryan

Last edited:

When I took it for its MOT (which it passed ) the duct between the

engine hot air outlet and the metal duct under the car burnt out.

Now I had to make it fit that duct as it is a 650cc engine and is oval

rather than round caused by getting it in the tight space . I may have left some fibers loose at the join ,but I thought these would be non combustable.

Has anybody else had this problem and if so what gave you used to get round this.I have found a supplier of SS flexible duct the correct size but would this transmit too much heat to the rest of the system.

This is was my only car I had without an extinguisher,but it has one now.

By the way all my cars are insured with Admiral , the Fiat cost all of £35 to add on.

Any thoughts

Bryan

engine hot air outlet and the metal duct under the car burnt out.

Now I had to make it fit that duct as it is a 650cc engine and is oval

rather than round caused by getting it in the tight space . I may have left some fibers loose at the join ,but I thought these would be non combustable.

Has anybody else had this problem and if so what gave you used to get round this.I have found a supplier of SS flexible duct the correct size but would this transmit too much heat to the rest of the system.

This is was my only car I had without an extinguisher,but it has one now.

By the way all my cars are insured with Admiral , the Fiat cost all of £35 to add on.

Any thoughts

Bryan

Last edited:

dk500

Member

- Joined

- Aug 17, 2013

- Messages

- 260

- Points

- 53

Hi

Are you talking about the hessian type ducting ?

I tried fitting them and also I have a 650 engine and could not get it to fit !

I ended up fitting the rubber type tubing after previously using the foil type air con tubing from Halfords which tore.

I also got a fire extinguisher incase but have read that the powder type can cause damage to the wiring loom when used ?

Darryl

Are you talking about the hessian type ducting ?

I tried fitting them and also I have a 650 engine and could not get it to fit !

I ended up fitting the rubber type tubing after previously using the foil type air con tubing from Halfords which tore.

I also got a fire extinguisher incase but have read that the powder type can cause damage to the wiring loom when used ?

Darryl

Hi. Was it ok temperature wise as I thought it may be to hot for the rubber ones. I have managed to find a stainless fexi but maybe to much heat transfer.

Further to extinguishers dry powder is best for car fires but very messy.

Then you have foam which is good and also messy then some of the gas ones (co2 halon , attf etc )As mentioned in an earlier post get out of the car and fight it from the outside.By the time I had stopped got my belts off the fire was already halfway over the roof .(I have the photo )even after operating the on board plumbed in one.

Further to extinguishers dry powder is best for car fires but very messy.

Then you have foam which is good and also messy then some of the gas ones (co2 halon , attf etc )As mentioned in an earlier post get out of the car and fight it from the outside.By the time I had stopped got my belts off the fire was already halfway over the roof .(I have the photo )even after operating the on board plumbed in one.

Taken from the Fiat 500 Club:

"Steel heater ducting under the car

This needs repositioning and/or changing for a 126 one. Remove the unit and the flexible pipe to the car heater duct. It is fiddly and to line up correctly best to do after engine and gearbox have been fitted. Existing rubber pipes can be used at both ends and then juggling the position of the steel box to fit.

Some people choose to buy different flexible pipe and cut to appropriate lengths to aid fitting.

Whatever solution is adopted, make tight all connections (zip ties very handy!) and secure the steel box well."

"Steel heater ducting under the car

This needs repositioning and/or changing for a 126 one. Remove the unit and the flexible pipe to the car heater duct. It is fiddly and to line up correctly best to do after engine and gearbox have been fitted. Existing rubber pipes can be used at both ends and then juggling the position of the steel box to fit.

Some people choose to buy different flexible pipe and cut to appropriate lengths to aid fitting.

Whatever solution is adopted, make tight all connections (zip ties very handy!) and secure the steel box well."

Are we talking about the pipe that connects to the thermostat housing down to the heater duct under the car?

If so on my 500 engine it is extremely close to the exhaust pipe and I have the rubber one fitted and never had any problems with it. I would be worried about putting any fibre or paper based pipe that close to the exhaust.

Also the heater duct on the 650 only needs a dent it in it to allow for the solenoid or you can buy one already shaped to allow for it. There shouldn't be a need to do any other modifying on it?

On the 650 engine the clearance between the exhaust and heater pipe is much better because they adjusted the thermostat housing to take it away from the exhaust. My 650 has a strange 2 into 1 exhaust on it that allows for really good clearance.

If so on my 500 engine it is extremely close to the exhaust pipe and I have the rubber one fitted and never had any problems with it. I would be worried about putting any fibre or paper based pipe that close to the exhaust.

Also the heater duct on the 650 only needs a dent it in it to allow for the solenoid or you can buy one already shaped to allow for it. There shouldn't be a need to do any other modifying on it?

On the 650 engine the clearance between the exhaust and heater pipe is much better because they adjusted the thermostat housing to take it away from the exhaust. My 650 has a strange 2 into 1 exhaust on it that allows for really good clearance.

The exhaust showing on the last engine has the rear pipe much higher and

away from the connecting pipe.Much better.

Now another question, has anybody out there put disc brakes on the front

whilst keeping standard wheels.( Not using available kit ) Fabricating parts should not be a problem

i.e. caliper mount and I may even have some mini ones lying around .

Thanks for all your help guys

Bryan

away from the connecting pipe.Much better.

Now another question, has anybody out there put disc brakes on the front

whilst keeping standard wheels.( Not using available kit ) Fabricating parts should not be a problem

i.e. caliper mount and I may even have some mini ones lying around .

Thanks for all your help guys

Bryan

Last edited:

Similar threads

- Replies

- 1

- Views

- 173