Hi everybody

I'm doing maintenance to my ducato 2.5 TDI 1995 caravan.

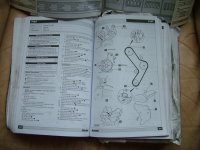

I disassembled all the pieces to access the cambelt, except the last metallic cover

I followed this nice video

I'm stuck at the pulley positioning and flywheel lock

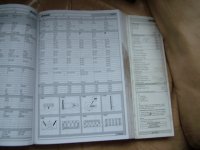

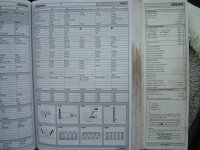

I tried to turn the engine shaft slowly until the cam pulley notch correspond to a mark on the top of the engine (a sort of arrow) but there is no way that the flywheel lock pin (8mm but also smaller) enters the hole on the gear chassis to lock the motor shaft movement.

Also turning the engine until the cambelt pulley notch returns to the aligment sign don't solve my problem.

Also the hole on the fuel pump pulley don't correspond to a hole on it's back, on the engine, so also in this case the locking ppin (5mm) can't insert and lock pulley.

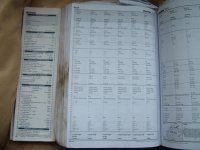

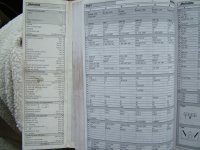

Do anyone have some piece of service handbook to show me this process or can give me some hint?

Thanks

Pietro

I'm doing maintenance to my ducato 2.5 TDI 1995 caravan.

I disassembled all the pieces to access the cambelt, except the last metallic cover

I followed this nice video

I'm stuck at the pulley positioning and flywheel lock

I tried to turn the engine shaft slowly until the cam pulley notch correspond to a mark on the top of the engine (a sort of arrow) but there is no way that the flywheel lock pin (8mm but also smaller) enters the hole on the gear chassis to lock the motor shaft movement.

Also turning the engine until the cambelt pulley notch returns to the aligment sign don't solve my problem.

Also the hole on the fuel pump pulley don't correspond to a hole on it's back, on the engine, so also in this case the locking ppin (5mm) can't insert and lock pulley.

Do anyone have some piece of service handbook to show me this process or can give me some hint?

Thanks

Pietro