- Joined

- Dec 22, 2019

- Messages

- 214

- Points

- 108

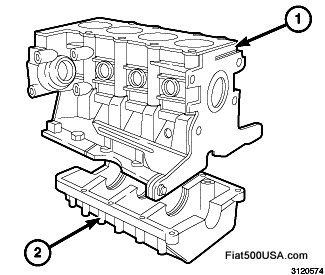

I have a replacement sump on the way for my 100HP as the thread for the sump plug isn't in very good shape.

I'm assuming there is no physical gasket and something like the Dirko sealant is the way to go?

Many thanks

I'm assuming there is no physical gasket and something like the Dirko sealant is the way to go?

Many thanks