I've seen this (dark car 3rd left) or similar split i.e. 2 piece rear engine cover in a few photos. It appears to be a bottom section hinged as per normal and a top section hinged at the top. Intriguing! Does anyone have any more details about what it is and if it's a commercial part or DIY?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Split engine cover

- Thread starter Noah500

- Start date

Currently reading:

General Split engine cover

Bigvtwin996

Established member

- Joined

- Jul 19, 2011

- Messages

- 1,348

- Points

- 430

I would say probably DIY from 2 covers.... cut so you could bend a flange over each peice to provide some strength and prob look factory rather than some dodgy spot welded strengthener...

I was thinking that... for a single cover it would have to be cut carefully and a flange welded on each part... though it might be difficult to get the curve right on both.

Bigvtwin996

Established member

- Joined

- Jul 19, 2011

- Messages

- 1,348

- Points

- 430

if you allowed 10mm on each edge you could (if good( cut slits and bend that edge over a former and tig the joins...

or you could Joggle a peice and as you say weld a flange on...

I thin the slit and ben would look best from a critical poin of view

or you could Joggle a peice and as you say weld a flange on...

I thin the slit and ben would look best from a critical poin of view

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,084

- Points

- 1,013

If would suggest that if you tried to make the 'split'cover from just one engine cover and wanted them to close closely and neatly in the middle, you will have a very difficult job to achieve that AND retain some amount of stiffness in each half. I think that the only way to do it properly would be to make it from 2 engine covers and be very precise with your cutting of them; at the bottom on th top half and the top of the bottom half. When you cut the covers into their 'halves' you will have to cut them so that, prior to folding them at the meeting point of the two halves, you still have the metal left on them for the overlap of what you want to use as the strengthening flange/fold-over.if you allowed 10mm on each edge you could (if good( cut slits and bend that edge over a former and tig the joins...

or you could Joggle a peice and as you say weld a flange on...

I thin the slit and ben would look best from a critical poin of view

Bigvtwin996

Established member

- Joined

- Jul 19, 2011

- Messages

- 1,348

- Points

- 430

thinking... if you had 2 covers and made the first half....

then it may make it easier to measure up the other half.....

rather than make 2 cuts and hope they line up....

you could even be very clever and the lower half have an extra lip for a seal or such so the top half lower edge has something to close up against..

Forgive my crude artwork

then it may make it easier to measure up the other half.....

rather than make 2 cuts and hope they line up....

you could even be very clever and the lower half have an extra lip for a seal or such so the top half lower edge has something to close up against..

Forgive my crude artwork

Bigvtwin996

Established member

- Joined

- Jul 19, 2011

- Messages

- 1,348

- Points

- 430

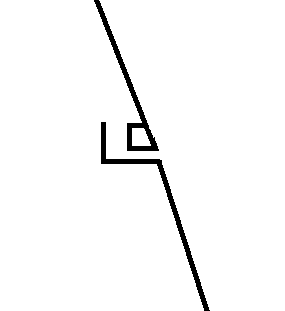

spoke with a mate (fabricator) about this... he has a totally different view....

Draw a line where you want the join...

now the next part is down to skill... make a template of the curvature of the panel along the line...

he said at his place they have one of those things that you use to mark fancy shapes for cuting tiles but its about 2m long

they would then cut that profile twice once for the bottom once for the top edges...

then shape it for the upper panel... and the lower, but the lower makigng sure the lip allowed for a seal to be applied...

the shapes being a sort of L

the lower lip longer so that there is space for the seal...

he said they would gut the line with a 2-3 mm disk thus allowing a small gap....

and weld the lips on to the panel edges

like this...

it should be welded at the ends to the sides of the panel and he would add some triangular strengtherners between the lips and the panels

if tig welded on the inside it should be possible to grind the edges round so it looks like it was pressed...

Draw a line where you want the join...

now the next part is down to skill... make a template of the curvature of the panel along the line...

he said at his place they have one of those things that you use to mark fancy shapes for cuting tiles but its about 2m long

they would then cut that profile twice once for the bottom once for the top edges...

then shape it for the upper panel... and the lower, but the lower makigng sure the lip allowed for a seal to be applied...

the shapes being a sort of L

the lower lip longer so that there is space for the seal...

he said they would gut the line with a 2-3 mm disk thus allowing a small gap....

and weld the lips on to the panel edges

like this...

it should be welded at the ends to the sides of the panel and he would add some triangular strengtherners between the lips and the panels

if tig welded on the inside it should be possible to grind the edges round so it looks like it was pressed...

I found a picture of another one

... looks really neat!

... looks really neat!