Hello Folks,

Progress Today...

Battery: I went online and found a 62Ah, 540 CCA, 3 year warranty, Exide battery for £54 from Euro Car Parts. Beat any of the local partstealers by miles ie. the same money would only get me a 1 year warranty, non-branded battery. The local equivalent to the Exide cost £75! No sale! So I ordered the Exide and got on the bus to my nearest Euro Car Parts Click & Collect depot - 2 hr round trip on the bus lugging a car battery, better be worth it... (extra bus fare on top of my bus pass: £3 return). That makes £57 for a good, branded, long warranty battery.

On the way home I dumped the new battery by the Multi and carried on home (the car is 1/4 mile from my house) to fetch the old battery and jump leads, to hook that up as well. Not taking any chances. Installed the new battery, hooked up the old battery to it, a few pumps on the gas pedal, turn the key, and...

THE ENGINE STARTED FIRST TIME, FIRST TURN OF THE KEY, FOR THE FIRST TIME IN 6 MONTHS !!!!!!!

YEEEEEEEEHHHHHAAAAAAAAAAAAAAAAA !!!!!!!

So the non-starter problem was caused by an old, dead battery.

Now to test the clutch and gears. As you'll recall, the tax and MOT have run out so the car's camped temporarily on the car park of a shut pub and I can't go any distance legally yet - in fact about 30 yards to the end of the car park. So... clutch in, into 1st -smooth as anything, handbrake off, clutch out, and a little trip to the end of the car park. Then tried Reverse - went into Reverse gear fine - like a new car.

All the electrics appear to be working OK including my cobbled-together alternative windscreen washer system (thought I was going to have to troubleshoot the electrics, but no). Check for leaks underneath... Oh no, what's that dripping... Oh it's only the washer water dripping down under the car from the windscreen. So far, touch wood, there is no evidence of leaking engine oil or gearbox oil. Maybe the new seals are OK after all.

What an amazing car ! It's been sitting completely dead outside my house for 6 months through a whole, wet, cold winter and the flipping thing starts first turn of the key (with a good battery). Amazing!

The car starting has saved me a £25 towing fee, plus god knows what to troubleshoot a non-starter, now I can get to the MOT garage under my own steam.

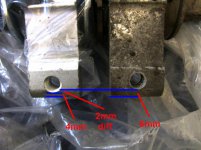

The car is booked into a garage on Thursday morning, for pre-MOT checks, prep and MOT. Before then there are a few little jobs to do: tighten the NS driveshaft bolts to the correct torque setting plus threadlock, new wipers, bit of a wash, new generic washer jets (£4 each, partstealer), put a proper exhaust rubber on to replace the cable-ties currently holding up the front exhaust, and maybe do the other OS wishbone which would save me about £30 in labour maybe (and give me a sense of completion having done the other wishbone), versus tackling a tricky job and not being able to get the new 'bone back on the car. Maybe the wishbone's OK anyway. Will sleep on it.

Still got the MOT to get through so not going to count my chickens yet. But Today things are looking up. Relief that it started, relief that the clutch and gears work, relief that all the electrics appear to work, so far no obvious showstoppers. We shall see...

Mark