Yes this is exactly how I did it, IIRC the volume was 45cc after skimming, that's about 8.6:1Yes if you plan to take the head off, its best to do a CC measurement to get a true C/R.. when i machined my heads i used a "burette" and a peice of clear acrylic plastic to measure the head chamber ML displacement. you can then measure the cyl bore, head gasket thickness and calculate the TDC volume. And by knowing the crank stroke, you can calculate a accurate C/R.

I don't have my notes in front of me, but if i recall, after shaving the head on mine, i settled around 9.4:1 CR. Any more, and things can get a bit spicy on pump gas.

When i rebuilt a 75 2.7 911 engine, its head geomerty and pistion shape did not like anything above 9.5:1 CR on our 91 octane gas. I had to add thicker base cyl shims to bring it down to around 9.3:1.. Just the way this particular engine was.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Looking to go faster

- Thread starter gordinir8

- Start date

Currently reading:

Tuning Looking to go faster

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,485

- Points

- 1,127

An interesting little snippet of information is that 1cc of water weighs 1 gram. Therefore, if you haven't got, or can't get, a "burette" the alternative way to calculate the cc of the combustion chamber is get a SMALL jug, put some water in it (about 60cc) and then weigh it on an accurate set of scales (wife's baking scales---with her permission!)---note the weight. Then VERY CAREFULLY (a very small funnel will help) fill the combustion chamber under the clear acrylic. When it is filled, re-weigh the jug--the difference in the 2 weights is the capacity in cc. I have found from experience that a couple of small 'breather holes' should be drilled in the acrylic sheet at the outer edge of the combustion chamber. If you don't do this, you will probably end up with an air 'bubble' under the acrylic which will give you a false reading. I drilled my acrylic out with a slow hand drill---less likely to crack the acrylic. I made up 4 bolts and big washers to hold the acrylic in place, fitted the head gasket that I was going to use, and greased all the contact surfaces to ensure water tightness.Yes if you plan to take the head off, its best to do a CC measurement to get a true C/R.. when i machined my heads i used a "burette" and a peice of clear acrylic plastic to measure the head chamber ML displacement. you can then measure the cyl bore, head gasket thickness and calculate the TDC volume. And by knowing the crank stroke, you can calculate a accurate C/R.

I don't have my notes in front of me, but if i recall, after shaving the head on mine, i settled around 9.4:1 CR. Any more, and things can get a bit spicy on pump gas.

When i rebuilt a 75 2.7 911 engine, its head geomerty and pistion shape did not like anything above 9.5:1 CR on our 91 octane gas. I had to add thicker base cyl shims to bring it down to around 9.3:1.. Just the way this particular engine was.

That is a great little tip!An interesting little snippet of information is that 1cc of water weighs 1 gram. Therefore, if you haven't got, or can't get, a "burette" the alternative way to calculate the cc of the combustion chamber

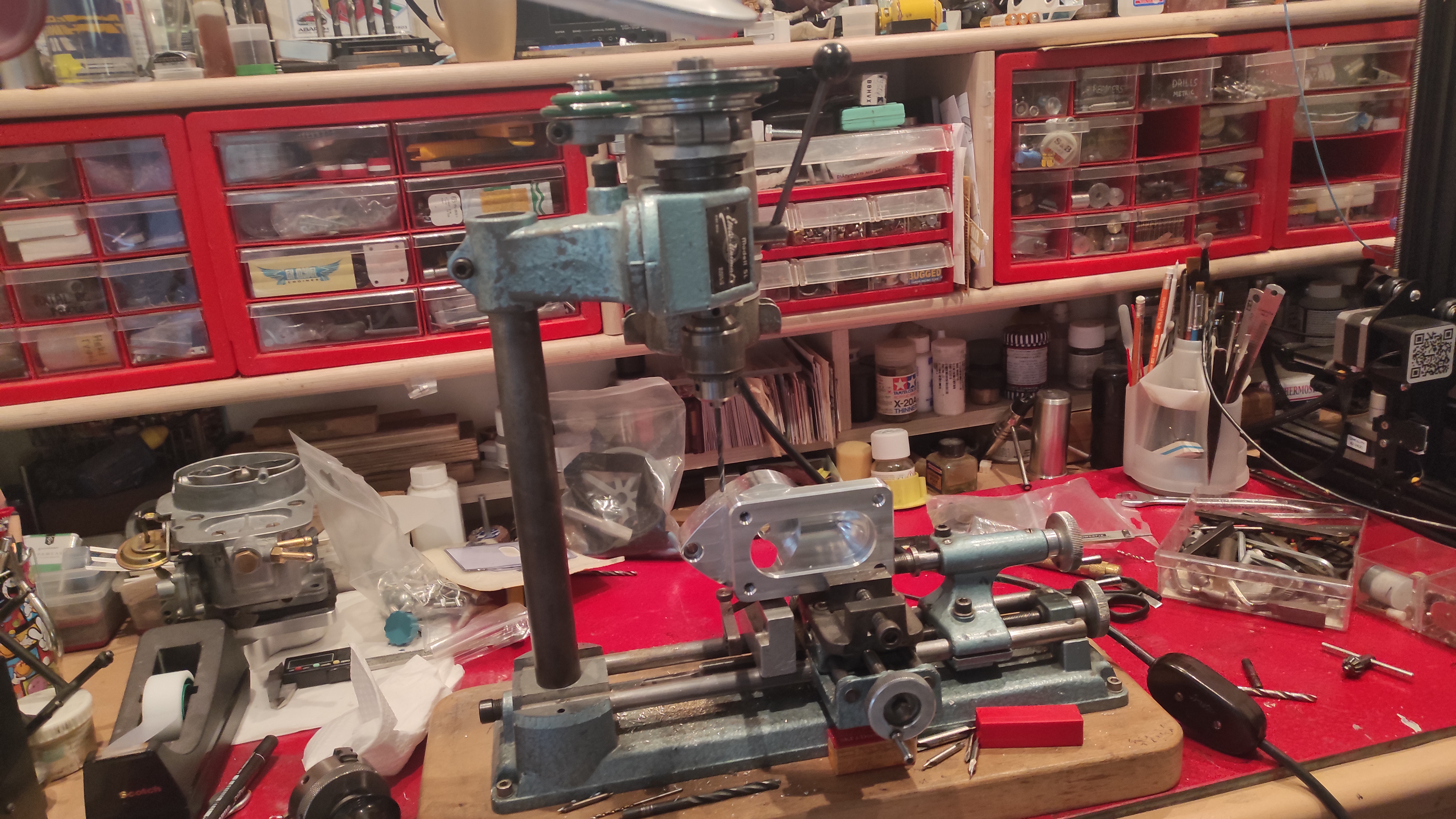

So while nanoplex ignition is on its way I received a Weber 30 DGF /252 carburettor from panda 30. All jests inside are original panda sizes and in general it is in good shape besides the fuel return brass tube that was missing but I made one in my little lathe. I hope it will fit as is without the need of changing jets etc. Called the local Weber dealer here in Athens to see if he had a repair kit and as soon as I gave him the number he replied...Is it from fiat Panda? This guy has a great knowledge of those carbs and for all fiat 500 options they use to work back in the day. He gave me a set from a Citroen GSA which had the same carb. Stay "tuned"

Hi Thomas, Your carb looks good, what jet sizes were fitted when it arrived? The standard set should be as follows -

Panda 30 standard in (brackets.)

Air Correction Primary - 1.90 - (1.90)

Air Correction Secondary - 2.00 - (2.00)

Primary main Jet - 1.12 - (1.10)

Secondary main Jet - 1.00 - (1.00)

Emulsion tubes are unmarked - (F8)

I have found that my engine runs very well with the standard set, only a rolling road set up would determine any changes.

Ian.

Panda 30 standard in (brackets.)

Air Correction Primary - 1.90 - (1.90)

Air Correction Secondary - 2.00 - (2.00)

Primary main Jet - 1.12 - (1.10)

Secondary main Jet - 1.00 - (1.00)

Emulsion tubes are unmarked - (F8)

I have found that my engine runs very well with the standard set, only a rolling road set up would determine any changes.

Ian.

Ian I have reed your carb post like a Bible (actually haven't ever reed the Bible but anyways) I have those exactly jets inside. After I complete engine break in I will take it to someone with analyser and see if any tune is necessary.Hi Thomas, Your carb looks good, what jet sizes were fitted when it arrived? The standard set should be as follows -

Panda 30 standard in (brackets.)

Air Correction Primary - 1.90 - (1.90)

Air Correction Secondary - 2.00 - (2.00)

Primary main Jet - 1.12 - (1.10)

Secondary main Jet - 1.00 - (1.00)

Emulsion tubes are unmarked - (F8)

I have found that my engine runs very well with the standard set, only a rolling road set up would determine any changes.

Ian.

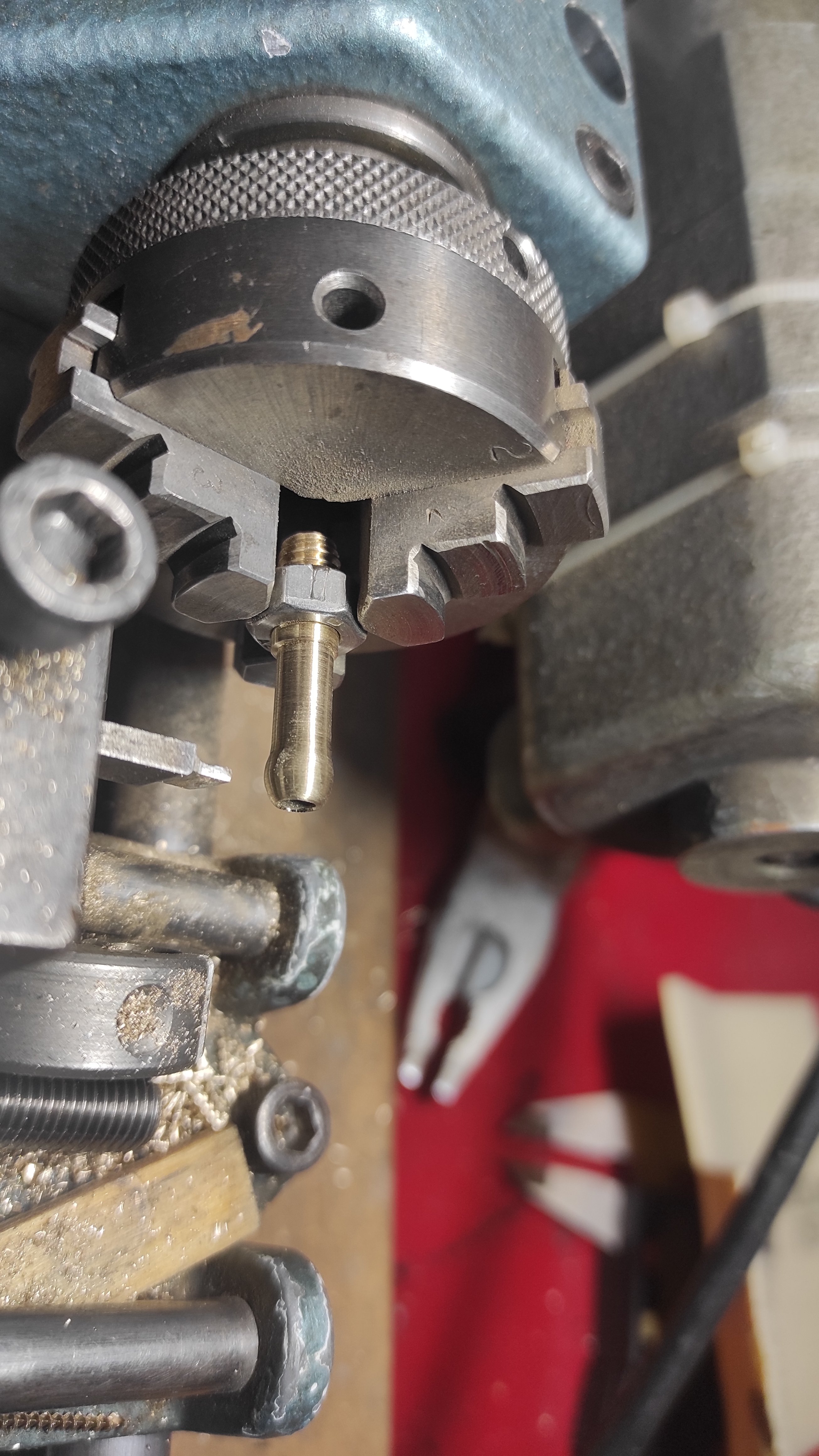

Nanoplex has a vacuum sensor connected between the inlet manifold and ECU. I have reed that it is not necessary to be there but why not? So I made this little vac output. Actually fiat 126 ELX has a second output that goes to a tank at the side of the engine bay but I don't know what it is

- Joined

- Sep 27, 2020

- Messages

- 412

- Points

- 173

I presume the vacuum sensor will allow the Nanoplex to advance the ignition timing under part throttle, offering improved part throttle performance and economy.

Whilst I can see that it's not 'nessesary' for the system to run and won't change the full throttle performance, to not utilise it would seem to me to be missing part of the point of using a more advanced system, like the Nanoplex, rather than sticking with points!

So looks like a good idea to me!

Whilst I can see that it's not 'nessesary' for the system to run and won't change the full throttle performance, to not utilise it would seem to me to be missing part of the point of using a more advanced system, like the Nanoplex, rather than sticking with points!

So looks like a good idea to me!

So as not to interfere with the induction too much with that type of manifold rather than use a nut and washer on the stud I use a mushroom head screw and shake proof washer on that internal mounting hole. Not shown on the picture but I also take a dremmel to the sharp internal corners. Also a Panda 30 manifold shown.

Nice idea, I also smoothened the head of the bolt I will use there on my lathe. I have a second manifold which is way smoother but needs probably a special adaptor which I don't have.So as not to interfere with the induction too much with that type of manifold rather than use a nut and washer on the stud I use a mushroom head screw and shake proof washer on that internal mounting hole. Not shown on the picture but I also take a dremmel to the sharp internal corners. Also a Panda 30 manifold shown.View attachment 403891

So here it is, I'm quite impressed on a first run about how little Car eats kilometres, not to mention how noisy it is. Still a few tweaks to do and also put the panda 30 intake housing which I will connect to the filter box. Still have to make a 3D printed adaptor for it.

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,485

- Points

- 1,127

Very good looking "wee beastie" Thomas. Making adapter plates for fitting 'non-standard' carbs on manifolds is really easy. Using either 8 or 10mm aluminium plate you drill it to match the manifold that you are using. You then cut it out to match the carb. Locating screws for the new carb can either be from the top, depending on where they are required, or from underneath the adapter plate using countersunk cap-head (allen) screws in carefully countersunk holes (so that the head of the screw is flush with the adapter plate). Loc-tite the countersunk screws in place and only use PLAN nuts on them. I have adapted 2 or 3 manifolds this way---tedious with a lot of filing, but very satisfying when it all goes together.So here it is, I'm quite impressed on a first run about how little Car eats kilometres, not to mention how noisy it is. Still a few tweaks to do and also put the panda 30 intake housing which I will connect to the filter box. Still have to make a 3D printed adaptor for it.

View attachment 403909

Design and print this intake adaptor for my panda 30 intake to 650 standard filter housing. This is a test shot, going to print it from carbon fiber type filament so it can take better engine bay heat. Taking fresh colder fan air is better than let the carb breath from the hot bay.

Les May

New member

Hi. I note your in Greece. We are tourists travelling through Greece and I desperately need a tyre or a tyre and rim. Can you please point us in the direction of a 500 classic part supplier.I was lucky enough (searching for two days now) and found a set of OEM fiat pistons 77.40 at a very reasonable price Tom. In Greece "breaking in" takes 1000 kilometres and oil change at 500 lol. Good thing is that weather is appropriate for breaking in so I guess I will take it easy up to 1000-1500 kilometres and then switch carburettor and see what's the difference.

Hi, just saw your post if you still need help please email me at [email protected] and I'll see what I can do.Hi. I note your in Greece. We are tourists travelling through Greece and I desperately need a tyre or a tyre and rim. Can you please point us in the direction of a 500 classic part supplier.