Thanks Ian I'll take a look at your thread, what is not clear to me is if all Weber 30 DGF are the same ( besides jets) or it have to be from fiat panda. Anyway more on carbs later because I am still running for the head repair and each work like welding, thread repair, valves seats etc has to be in a different shop no-one is doing all the work. So I'm on the run.Hi Thomas, if you look at my old thread @

Weber 30 DGF 1/252 service

you will find all the information you need about the correct jets for the carb. Just in case the carb you find does not have the original jetting.

For information It was recommended by my engine man that I use a new set of jets - All one size above standard to help with the running in process - the richer jets help keep the piston crown cooler and when run in change back to the leaner original jets. Hope this helps.

Ian.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Looking to go faster

- Thread starter gordinir8

- Start date

Currently reading:

Tuning Looking to go faster

No it's is metric, I'll visit the machine shop tomorrow that deals with honing and he will tell me if we can proceed or not.Could it be that it's measured in Imperial...that does seem to happen sometimes with engine component dimensions. 0.010" oversize would be 0.254mm.

Sorry to hear about the broken ring.

You need one from a panda 30 otherwise you are wasting your time and Weber jets are as cheap as chips. Every modified engine has its own characteristics so whilst a standard 30 carb may be a perfect fit you may want to run a gas analyser to check.Thanks Ian I'll take a look at your thread, what is not clear to me is if all Weber 30 DGF are the same ( besides jets) or it have to be from fiat panda. Anyway more on carbs later because I am still running for the head repair and each work like welding, thread repair, valves seats etc has to be in a different shop no-one is doing all the work. So I'm on the run.

I do not recognise those markings but I just had some barrels bored out for 0.2mm o/s pistons which is 0.008” on the diameter so could almost be licked out by a cat so with a proper machinist you should have no problems. Just check the gap on the ringsGuys is this piston supposed to be 04 oversize? Because I am measuring it and it is 77.28 more or less but not 77.40 plus that it came with broken ring but that's another story.

View attachment 400940

Machine shop told me they are 040 so we are back on track. He will bore cylinders an will be fine.I do not recognise those markings but I just had some barrels bored out for 0.2mm o/s pistons which is 0.008” on the diameter so could almost be licked out by a cat so with a proper machinist you should have no problems. Just check the gap on the rings

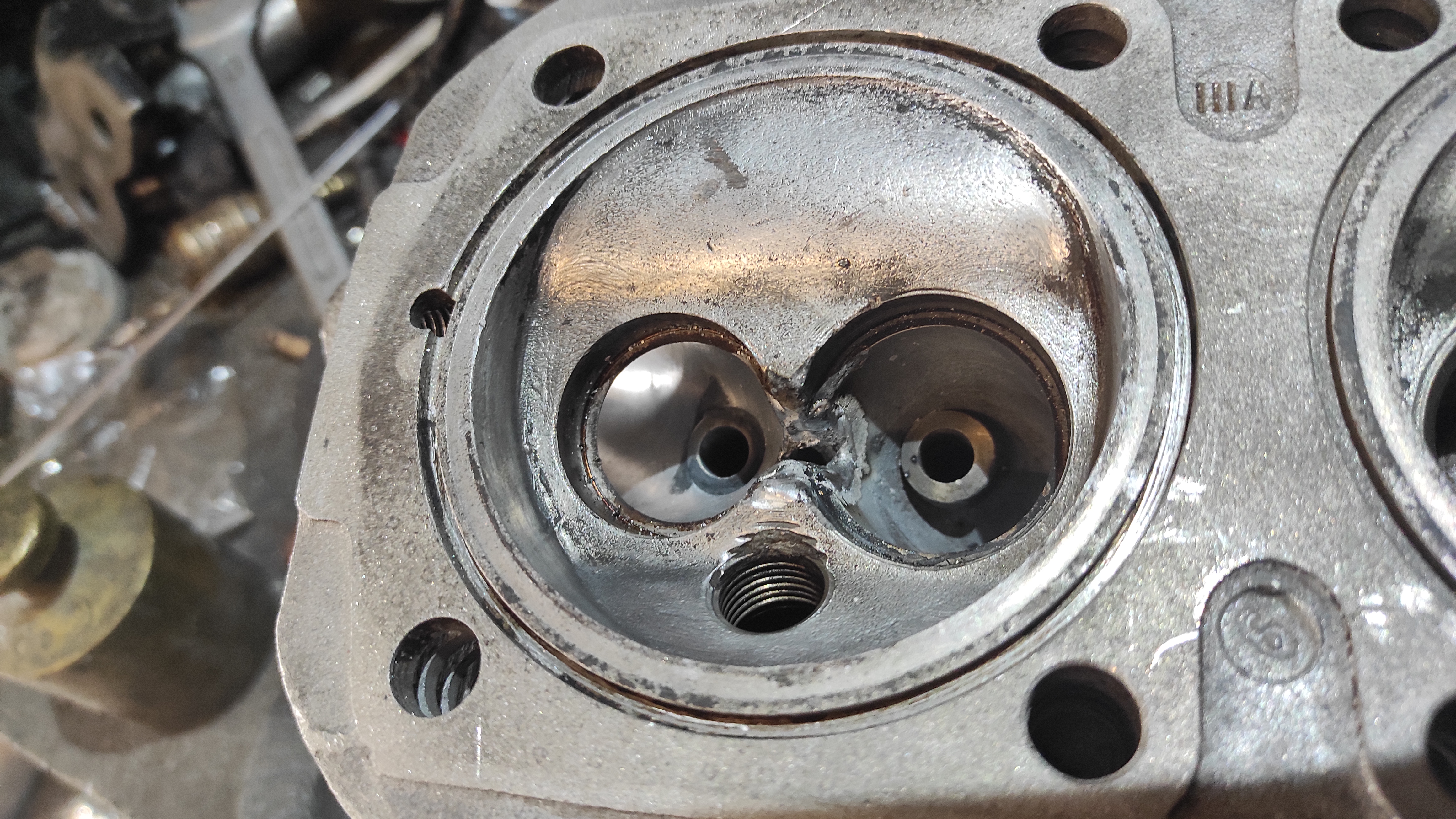

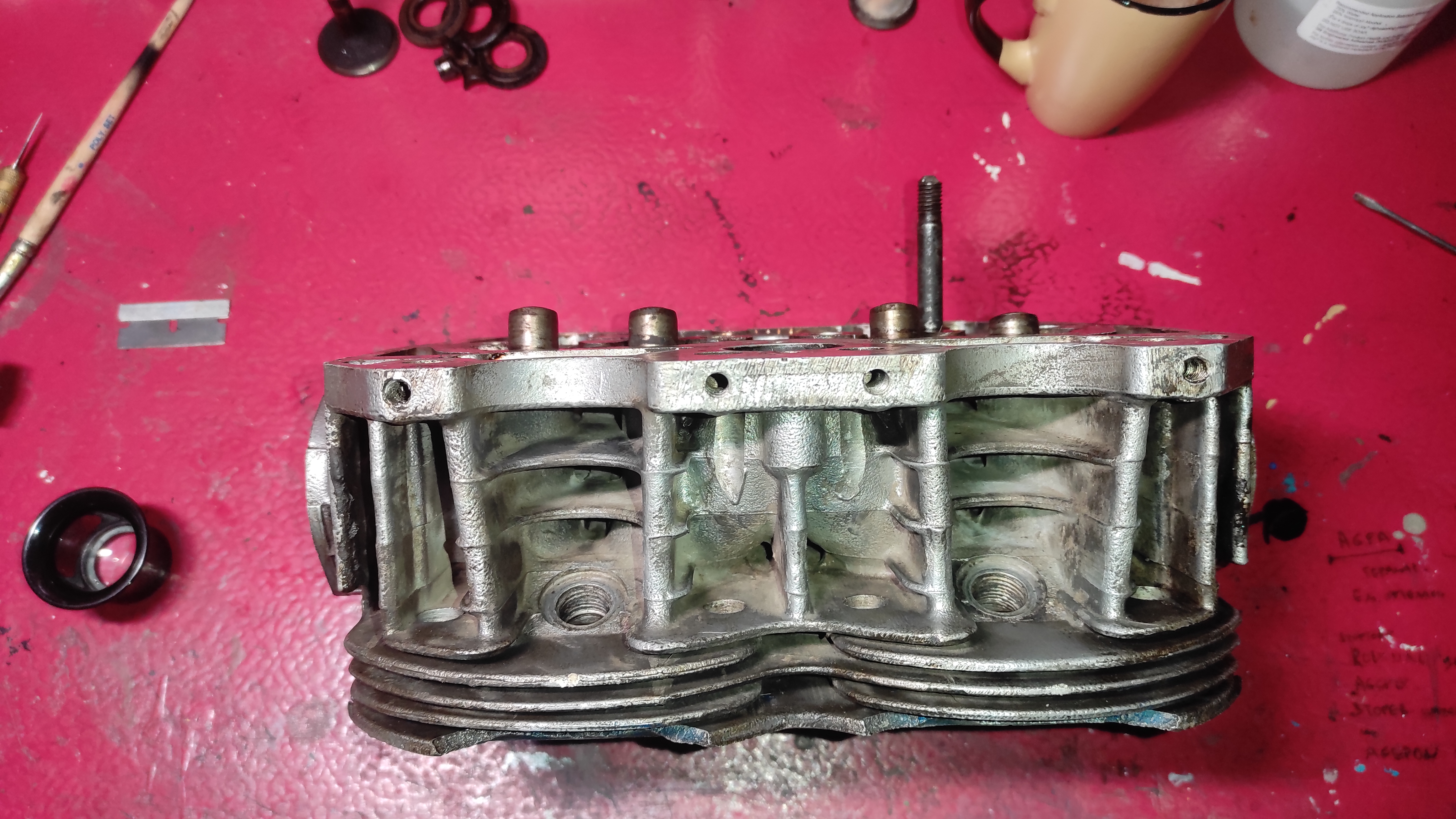

And here is the head after removing the cracks. I am not sure if the welder that did the work did it well but Monday morning I will take it to an expert one ( that I discovered afterwards) to repair the plug hole and tell me his opinion about it. I have start to rework it inside and do it further after valve seats area is ready to accept new seats. I'm in deep waters right now.

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,114

- Points

- 1,021

All you can do Thomas is clean up the combustion chamber part (as you have started to do) and then re-appraise the sitution when you see what is removed when the new valve seats are fitted.And here is the head after removing the cracks. I am not sure if the welder that did the work did it well but Monday morning I will take it to an expert one ( that I discovered afterwards) to repair the plug hole and tell me his opinion about it. I have start to rework it inside and do it further after valve seats area is ready to accept new seats. I'm in deep waters right now.

View attachment 400990View attachment 400991View attachment 400992

Shouldn't matter.

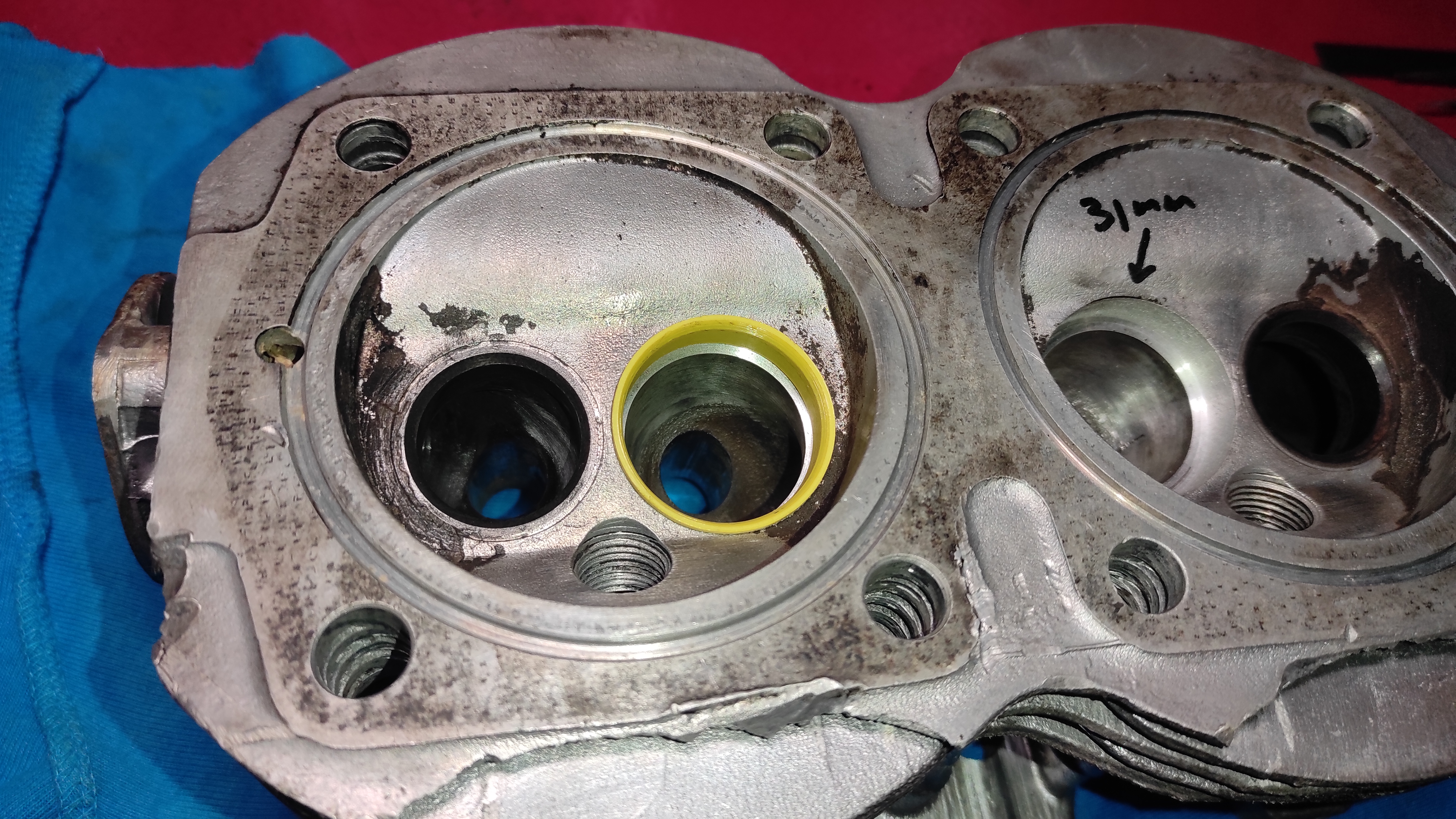

Scored this today for just 47 euros, seems to be free of cracks but has two fins broken. Weird that valve guides have migrated otherwise with very good valve clearances. I am really sceptical if 35mm valves will fit since distance between inlet and outlet is less than 2mm

Got cylinders from "Rectifieur". In Greece for anything related to cars like parts etc we are using french wording. So we call reboring "Rectifieur" Pistons are nice and tight now and hope free of slapping. Any of you recommend cooper seals instead of standard paper?

Last edited:

Update: Removed valve seats and valve guides so I can rework the head to accept 35mm inlet valves. Made a 3D printed dummy valve seat to use it as guide and removed unwanted material. Everything inside will be smoothed and mirror polished. Machine shop told me that he can make valve guides 7mm shorter and add seals on valve steams but I haven't decided yet if it is necessary. I wonder with all those mods what the final hp output will be.

If you do valve stem seals, just do them on the intake valve. No need for seals on exhaust valves for many reasons. This is a small trick i do to extend guide life on classic 911 engines.

When i did the work on my 500 engine, i also just did seals on the intakes. You will get a small puff of smoke on startup due to no seals on the exhaust, but the additional oil slowly running down the exhaust valves will extend its life significantly.

Intake valves dont see the extreme heat that exhaust valves do, so oil lubrication is not as important for life expectancy.

I can pull up the part number for the "modern" seal i used for the intake valve guides, but it will require you to slightly shorten the top of the guide to allow enough spring to seal clearance. You will also need to slightly machine a retaining lip on the guide of your replacing them. it is also possible to dremel a retaining ridge for the seal to grab while the guide is still in the head.

When i did the work on my 500 engine, i also just did seals on the intakes. You will get a small puff of smoke on startup due to no seals on the exhaust, but the additional oil slowly running down the exhaust valves will extend its life significantly.

Intake valves dont see the extreme heat that exhaust valves do, so oil lubrication is not as important for life expectancy.

I can pull up the part number for the "modern" seal i used for the intake valve guides, but it will require you to slightly shorten the top of the guide to allow enough spring to seal clearance. You will also need to slightly machine a retaining lip on the guide of your replacing them. it is also possible to dremel a retaining ridge for the seal to grab while the guide is still in the head.

I do hate to contradict any postings, but will just say that I have two Panda 30 heads one from 83 and one from 86. The earlier head only has a valve stem seal on the intake, while the later head has the seals on both valve stems. These are factory fittings not later mods and must have been required by Fiat for these two cylinder engines in the later years of production. The most probable reason is to combat unnecessary emissions, but there may be other reasons too.If you do valve stem seals, just do them on the intake valve. No need for seals on exhaust valves for many reasons. This is a small trick i do to extend guide life on classic 911 engines.

When i did the work on my 500 engine, i also just did seals on the intakes. You will get a small puff of smoke on startup due to no seals on the exhaust, but the additional oil slowly running down the exhaust valves will extend its life significantly.

Intake valves dont see the extreme heat that exhaust valves do, so oil lubrication is not as important for life expectancy.

I can pull up the part number for the "modern" seal i used for the intake valve guides, but it will require you to slightly shorten the top of the guide to allow enough spring to seal clearance. You will also need to slightly machine a retaining lip on the guide of your replacing them. it is also possible to dremel a retaining ridge for the seal to grab while the guide is still in the head.

Ian.

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,114

- Points

- 1,021

When I was looking for valve-guide seals for my Panda30 head, I came across "Elring"---the seals that you will need are very possibly the same as I got---part number "195-925". The valve guides WILL need to be machined at the top of the guide to allow fitment. My Panda30 head must be an early one as the seals are only on the inlet.I wonder if lubrication is the same or worse with the seals on, Sorry to say that but i really don't care about emissions at the moment. I am one of those guys with engine breather exposed at the road

Hi Thomas, I was concerned about lubrication too, but after replacing the seals on both heads I have not had any problems regarding lubrication. Minimising oil ingress to the cylinder should be a priority IMO.

Ian.

Ian.

Agreed yes, the main reason for seals on the exhaust guide is purely for emissions.The most probable reason is to combat unnecessary emissions, but there may be other reasons too.

Ian.

A intake seal is a must though, because at prolonged idle, intake vacuum will suck plenty of oil thru the guide to cause a nice smoke screen upon takeoff, usually from a stop light.

Again its not critical to omit or add the exh valve guide seal, the performance of our 500 engines isnt astronomical, if it was more inclined towards racing and extreme repeditive high rpms, little tricks like this help prolong component life.

Talked with the machine shop this morning, he told me that he will mod it and put seals on. Next step is to measure head volume and calculate how much to skim the head. Since I don't want to push it much I will go for 9:1 ratio with 06mm gasket.

Hi Thomas, I must say that you are going about the head skimming the best way by starting with the head volume. This way you can measure all the required numbers to get the deck height correct and the squish band spot on at 1mm. I was not so lucky as both of my heads had been adjusted so it took a lot of swapping of gasket sizes and lower spigot support plates to get the result needed. we even had to remove 1.5 mm from the top of the pistons

Ian.

Ian.