Hy,

The problem I’m having with my grande punto 1.4 8V is while I drive in any gear and suddenly release gas pedal I get instant decrease of rpm (feels like kick when engine mount is bad).

Engine is not decreasing speed softly like it should I think.

All three engine mounts are installed new, clutch is new, Spark plugs, air filter. MAP cleaned.

The car idle run smoothly, acceleration is good, no other problems while driving , only that let’s say kick down when suddenly releasing gas pedal.

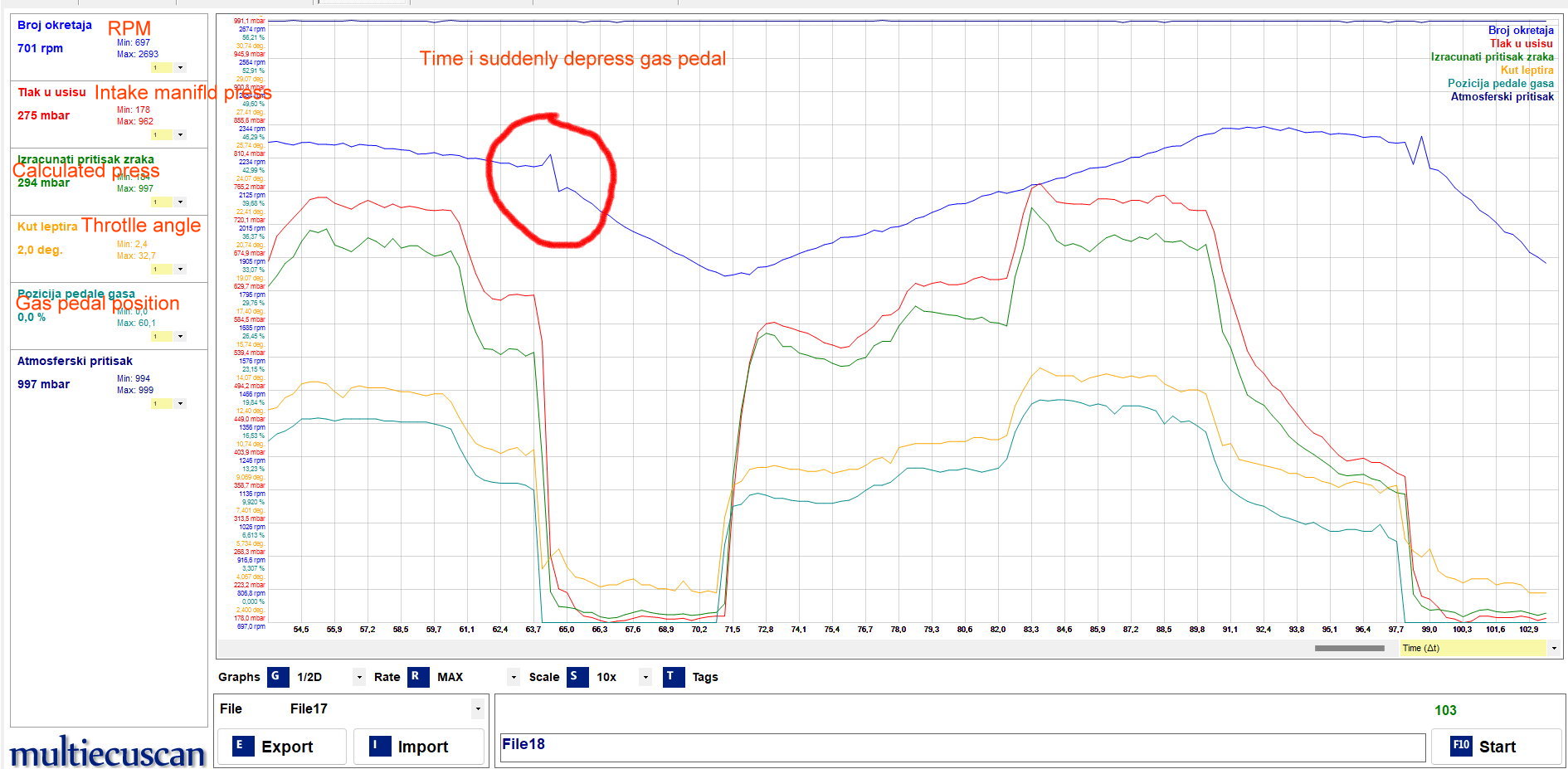

So I manage to connect car to MES but I cant thell what is bad.

I suspect Throttle angle position is strange when i release gas pedal. There is some spike.

Should it go straight down like, rpm, and gas pedal position?

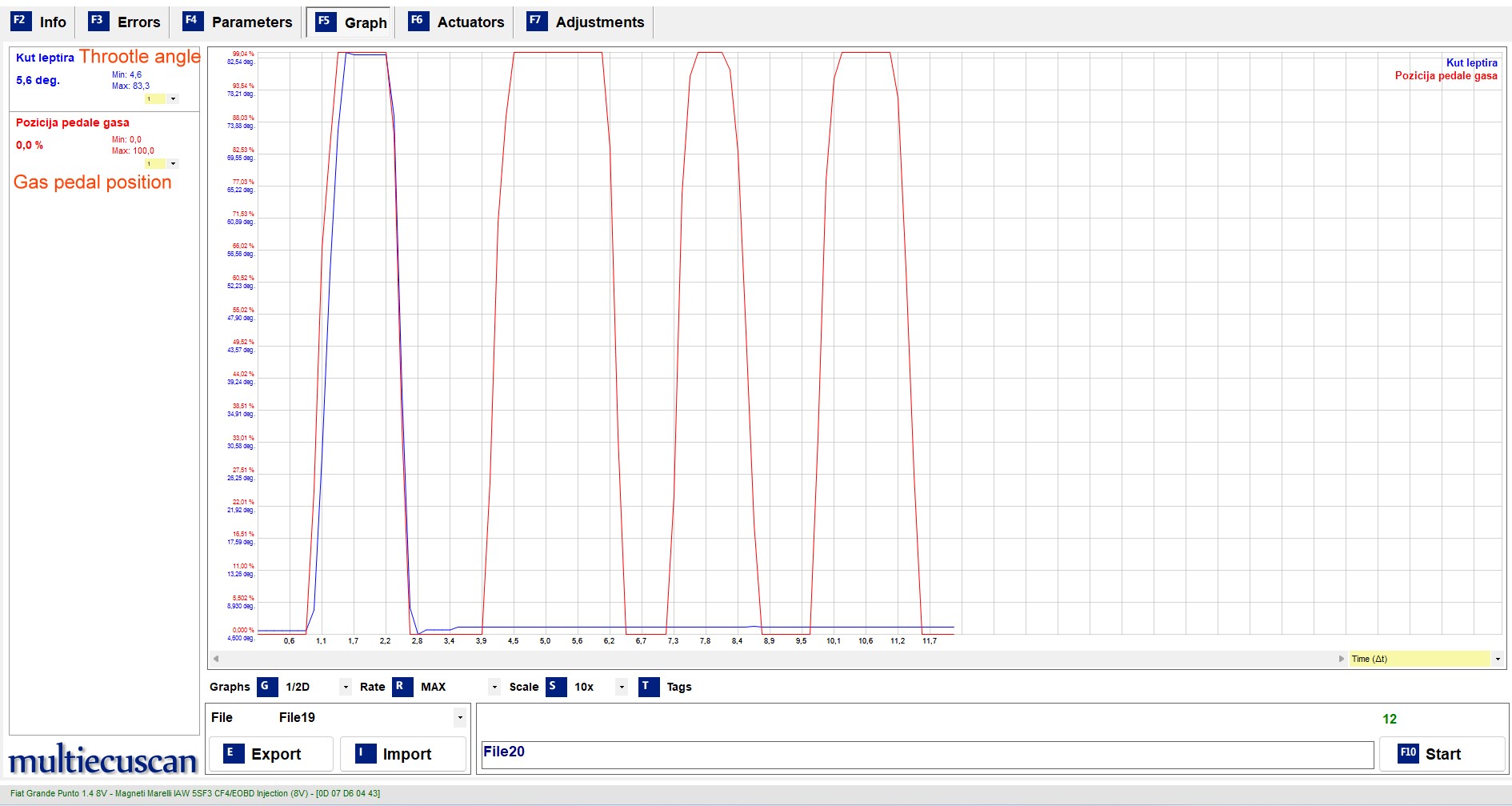

Also graph throotle angle and gas pedal position. My throotle angle go only up to 83,3 % , but i can only catch it short time because it's responding only couple seconds when i give contact with key.

Any help or advice is appreciated , thanks

The problem I’m having with my grande punto 1.4 8V is while I drive in any gear and suddenly release gas pedal I get instant decrease of rpm (feels like kick when engine mount is bad).

Engine is not decreasing speed softly like it should I think.

All three engine mounts are installed new, clutch is new, Spark plugs, air filter. MAP cleaned.

The car idle run smoothly, acceleration is good, no other problems while driving , only that let’s say kick down when suddenly releasing gas pedal.

So I manage to connect car to MES but I cant thell what is bad.

I suspect Throttle angle position is strange when i release gas pedal. There is some spike.

Should it go straight down like, rpm, and gas pedal position?

Also graph throotle angle and gas pedal position. My throotle angle go only up to 83,3 % , but i can only catch it short time because it's responding only couple seconds when i give contact with key.

Any help or advice is appreciated , thanks