Hi chaps.

Got a 2005 1.9 JTD115 dynamic.

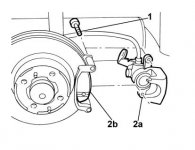

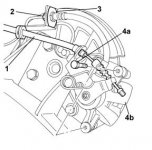

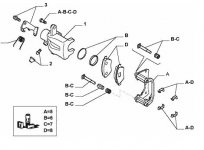

Wanted to change Rear pads, but can't get the caliper to slide off the disc because the discs are too worn and the pads won't go over the unworn outer shoulder. Because the pistons won't push back the 6mm or so (the unworn disc edge sticks out about 3mm on each side of disc from the worn surface), I can't see how to do the job. I can't get the caliper off the disc to get at it to retract the piston to fit the pads.

I can't get at the disc to angle grind the raised edge off on either side because of the shroud that goes around behind the disc. Does anyone know how to get this shroud off? Looks like it's bolted on with the 4 main bolts holding the stub axle on.

Any help much appreciated. And yes, I know how to retract the pistons once I get the caliper to slide off the disc. Need to get these damn shrouds off....:bang:

Got a 2005 1.9 JTD115 dynamic.

Wanted to change Rear pads, but can't get the caliper to slide off the disc because the discs are too worn and the pads won't go over the unworn outer shoulder. Because the pistons won't push back the 6mm or so (the unworn disc edge sticks out about 3mm on each side of disc from the worn surface), I can't see how to do the job. I can't get the caliper off the disc to get at it to retract the piston to fit the pads.

I can't get at the disc to angle grind the raised edge off on either side because of the shroud that goes around behind the disc. Does anyone know how to get this shroud off? Looks like it's bolted on with the 4 main bolts holding the stub axle on.

Any help much appreciated. And yes, I know how to retract the pistons once I get the caliper to slide off the disc. Need to get these damn shrouds off....:bang: