ladaspeed

New member

In my efforts to track down the cause of the flat spot issue I thought I would fit an o2 sensor to vizzle the stoichiometricizzle.

17 μlarge got me a jaycar kit which even someone as deeply electrically retarded as me could slap together in a trice as there are only 4 things on it. It took longer to figure out the values of the resistors than the entire length of the rest of the project.

A Toyota Vitz o2 sensor and a friendly supplier who gave me two M18 metric fine half nuts sealed the deal;

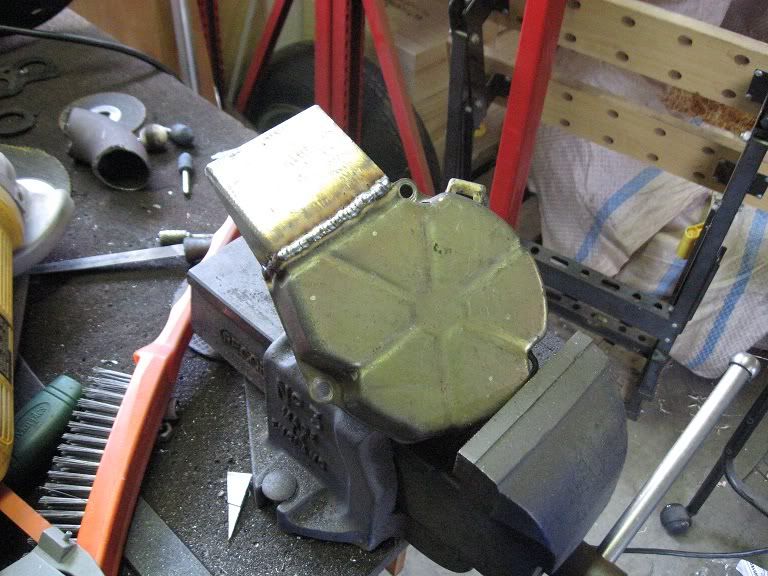

And the prize for the roughest ever fuel air indicator mounting goes to;

Well that would be me then.

Result? - I had no real baseline to judge it from, other than the pot was wound fully anticlockwise to get it out of the yellow and into the green, so it is probably running rich on average. However, it is remarkably consistent under all load conditions, and making it do it's flat spot dying/coughing/farting thing didn't really affect the ratio, so it is hard to say it it is caused by leaning out or getting too rich.

As this was the point of the episode, it is probably been a waste of time...

mmmm pretty lights though.

17 μlarge got me a jaycar kit which even someone as deeply electrically retarded as me could slap together in a trice as there are only 4 things on it. It took longer to figure out the values of the resistors than the entire length of the rest of the project.

A Toyota Vitz o2 sensor and a friendly supplier who gave me two M18 metric fine half nuts sealed the deal;

And the prize for the roughest ever fuel air indicator mounting goes to;

Well that would be me then.

Result? - I had no real baseline to judge it from, other than the pot was wound fully anticlockwise to get it out of the yellow and into the green, so it is probably running rich on average. However, it is remarkably consistent under all load conditions, and making it do it's flat spot dying/coughing/farting thing didn't really affect the ratio, so it is hard to say it it is caused by leaning out or getting too rich.

As this was the point of the episode, it is probably been a waste of time...

mmmm pretty lights though.