The 1.2 engines are in a lower emission bracket in the UK so it makes me wonder about the maps for the 1100. I fitted a Punto MF59 1.2 ECU to the 1.1 and it felt lacking in power.?

Interesting. My guess is that both engines are well within these brackets anyhow, so little to do with the mapping. At least fuel mapping, as this is corrected by lambda anyhow. Lacking power - my guess it was simpy overfueled, or if the two engines use different injectors (I would not believe so), then there might be effecive underfueling.

How much difference in mapping is there between the Euro 3 and 5 engines?

Does the Mani Cat require an adjustment in the mapping to warm it up quicker?

I am very dumb when it comes to the Euro numbers (who cares

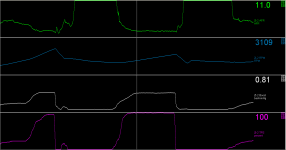

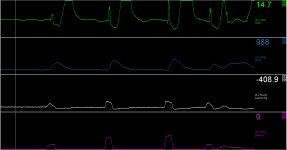

), but I can tell you that the newer IAW programs have a considerably different architecture and map design than the old ones. And you can call me crazy, but I can actually feel it when driving. I got my maps in the 4AF close to where I want them to be and according to the AFR readings it is OK, yet I can feel under the accelerator pedal the engine having different "habbits". It's this thing when you change cars from one to another, you have to learn to press the throttle in the right moment and to the right depth all over again.

As for the second question, I am not sure if that is required, but the maps are defo made to go to the stoich mixture of 14.7 AFR as soon as the engine can handle it and keep stable idle. The manicat heats itself up quickly from the signle fact of being where it is.

While I am at it, I have been playing with 4AF a bit more, I am getting to make it play along fully. I managed to figure out how important the after start enrichment is - make it too high and the engine chokes a bit right after start but keeps alive, make it too low and the engine starts up like crazy (revs going up and all) to instantly die afterwards. At least this is my experience so far. I have to find the golden middle.

I also found out that this ECU is very aggressive in charcoal canister valve operation. From what I can tell so far, this is what gives me occassional fuel flactuations. My charcoal canister system is defo different from the one in Sei, so the ECU most likely is simply not operating it as it should. My next step will be to try to disable it altogether. (Actually, even with the old ECU I had nothing but trouble getting the canister operation right).