Since I will remove my 500 head to see what's inside I am thinking to increase the compression a little to make little beast just a little faster, I will probably port and Polish the head just to play with it and remember the old tuning days. I was wondering how much I should get it down and what to expect in compressio ratio increase. Is there a ultimate formula? I haven't mesure it as is now but I will do before any modification. Also any advise in opening the ports will be welcome.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Head milling to gain compression.

- Thread starter gordinir8

- Start date

Currently reading:

Tuning Head milling to gain compression.

AndrewHarvey

Established member

- Joined

- Jan 17, 2015

- Messages

- 1,471

- Points

- 290

Milling will remove the gas ring - which protects the car driver from exhaust gasses should the HG fail.

Valve guides can be cut back as they hang in the gas flow.

Porting and polishing is useful - bigger inlet valves better..

Valve guides can be cut back as they hang in the gas flow.

Porting and polishing is useful - bigger inlet valves better..

Milling will remove the gas ring

I made that mistake the other week; the 499 head doesn't have a gas ring in any case as Nathan pointed out to me.

I have seen a head for sale on Ebay which had been skimmed-off so much that the first cooling fin was almost gone.

Paolo66

Established member

- Joined

- Feb 6, 2013

- Messages

- 1,004

- Points

- 235

I have seen a head for sale on Ebay which had been skimmed-off so much that the first cooling fin was almost gone.

That was a shocker Peter and they wanted 300 quid for it when you get a new one for 200 euro.

What do you mean by ''it has no gas ring''? it has, that is why the hollow bolts.<br />

Am i missing something here?

The rings on the 499 are only on the barrels...it surprised me too!

Am i missing something here?

The rings on the 499 are only on the barrels...it surprised me too!

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,462

- Points

- 1,121

The very early 500 (and I think 500Ds) had flat undersides to the cylinder head (the part that goes against the head gasket). Fiat later modified the heads to have a machined ring on the underside of the cylinder head and a hollow bolt, which holds the shrouding in place and is located just under the exhaust manifolds (1 per end). This hollow bolt is open to this machined ring, the theory being that if the head gasket DOES blow, the combustion fumes will exhaust out through these hollow bolts rather than be blown through the car with the 'heater air'. If your heads have this machined ring, you MUST NOT have the head skimmed to the point that the ring disappears. I would suggest that you have the head 'flash-skimmed' (i.e. just enough taken off to absolutely guarantee flatness), and then use a thin copper head gasket. These can be obtained from a number of the usual parts suppliers, but if you get stuck, I have a spare one.

As to 'porting' the head, if you would like to contact me direct, I will go through it for you.

Bigger valves---you only need to enlarge the inlet valves, but it all depends how far you want to go. To fit bigger valves, you have to fit bigger, matching valve seats--a machine shop job. If you fit bigger valves to justify that job, you either have to start playing around with carb jets or get a bigger carb, and manifold---it all starts adding up.

For a cost effective 'warm-up' I would skim the head, fit a thin copper head gasket, leave the valves standard, port the head, fit a better cam (35/75/75/35 is a good 'all-rounder'), time the cam very carefully when you fit it (with new timing gears and chain) with a timing disc, fit a better exhaust and re-jet the carb--poss up 1 size on both main and idle jets.

If you do the above to a '650' engine, you will be pleasantly surprised at the increase in performance, without leaving too big a hole in your pocket. If you are sticking with a '500' engine, you will still get an appreciable increase in performance.

As to 'porting' the head, if you would like to contact me direct, I will go through it for you.

Bigger valves---you only need to enlarge the inlet valves, but it all depends how far you want to go. To fit bigger valves, you have to fit bigger, matching valve seats--a machine shop job. If you fit bigger valves to justify that job, you either have to start playing around with carb jets or get a bigger carb, and manifold---it all starts adding up.

For a cost effective 'warm-up' I would skim the head, fit a thin copper head gasket, leave the valves standard, port the head, fit a better cam (35/75/75/35 is a good 'all-rounder'), time the cam very carefully when you fit it (with new timing gears and chain) with a timing disc, fit a better exhaust and re-jet the carb--poss up 1 size on both main and idle jets.

If you do the above to a '650' engine, you will be pleasantly surprised at the increase in performance, without leaving too big a hole in your pocket. If you are sticking with a '500' engine, you will still get an appreciable increase in performance.

That was a shocker Peter and they wanted 300 quid for it when you get a new one for 200 euro.

It certainly was: mind you, you'd be lucky to find a new one for 200 Euro, especially as you would expect it to have had the "unleaded" treatment.

On the blow-by groove, I have two 499cc heads, one from '69 and the other '71, so near the end of production. Neither has the machined groove and nor have they been worked-on.

Last edited:

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,462

- Points

- 1,121

Very interesting Peter---I have (long story which I won't bore you with) a pair of 500 BARRELS, which have 'blow-rings' rings cast into them--as do all the 650 barrels that I have. Could it be that the 'blow-by' ring in the head was only introduced with the 126 engines (and 500R?) as it definitely appears in the 126 594cc heads.

My head has the hollow bolts so i thought that gas ring was a mandatory for all heads. I will get back when i have my head removed with pictures. On the other hand if there is a groove i think that they can skim the head down and rework the gas ring. On the other other hand i believe that this gas ring is not so necessary, if you blow you head gasket some fumes will get into the cabin and you will now that it is a time for new gasket, nobody is going to die. Also my car now has so much fumes you will think the exhaust is directed to the cabin and i have deactivate the heater duct.

i believe that this gas ring is not so necessary, if you blow you head gasket some fumes will get into the cabin and you will now that it is a time for new gasket, nobody is going to die. Also my car now has so much fumes you will think the exhaust is directed to the cabin and i have deactivate the heater duct.

What is the thickness of this gasket anyway?These can be obtained from a number of the usual parts suppliers, but if you get stuck, I have a spare one.

Last edited:

AndrewHarvey

Established member

- Joined

- Jan 17, 2015

- Messages

- 1,471

- Points

- 290

The copper ones come in various thicknesses to suit your needs.

I would be hesitant to spend much time/ money for on a 500 unit when a 650 yields much better results......unless the originality of a 500 unit is required.

I would be hesitant to spend much time/ money for on a 500 unit when a 650 yields much better results......unless the originality of a 500 unit is required.

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,462

- Points

- 1,121

Most of the copper head-gaskets are 1/2mm thick (Axel Gerstl and Van de Laan). I would strongly advise you NOT to skim the 'blow-ring' off and then try and re-machine a ring back into it. (a) You will end up with far too high a compression ratio and, (b) I don't know how much metal there is in the head to allow this. Also, don't forget---the more you skim the head down, the more fettling you have to do to bolt the shrouding back on, because you are effectively lowering the head vis-a-vie the barrels.

Well to be honest I belive that skimming the head more than 05,08 or 1mm at the top is enough for this engine. I don't know how deep is the gas ring but I think taking it down that much that the ring will deesapear is more than it needs, it will probably bring other problems in the end. I will ask the machine shop to skimm the head up to the point it will be clean and dead flat, measure it then and decide if I will go further but I will not exceed 1mm top, this is how I am thinking of it. I will have a clear picture as soon as I have everything on my bench.

I think that you could go for a 1mm skim and run a 0.5mm copper gasket or 1.5mm and run a standard head gasket to get a reasonable compression ratio pushing on to about 9:1. As for gas rings in the cylinders I checked the ones I have here and the 499, 594 & 652 ones all have the gas escape ring. The 750 & 795 ones do not. If you do not have the hollow bolt and a gas escape ring you run the risk of burning a groove through the ally head if the head gasket blows.

Hi Thomas,

Before you dismantle your engine, you could determine the existing compression ratio.

Support engine so that a spark plug is at the highest point. With a piston at t.d.c. and both valves closed, fill the cyl. with light oil/paraffin etc up to the spark plug hole. Note the amount of fluid used. (= clearance volume) Drain the oil used.

Rotate the crankshaft so that the piston is now at b.d.c. with both valves closed (you might have to back-off the valve adjusters or remove the rocker shaft to ensure this). Refill the cylinder with oil etc to reach the spark plug hole. Note the amount of fluid used (=clearance volume + swept volume)

Divide the 2nd amount by the 1st amount., this gives you your C.R. no.

Compression Ratio = (Swept volume + Clearance volume) divided by Clearance volume

From these figures you can calculate the effect on C.R of using different thickness head gaskets. You might also be able to calculate the effect of milling different amounts from the cyl. head face.

When you remove your old head gasket, don't toss it away. Measure it's thickness, so you'll know what the thickness of a composite is when installed.

Good Luck with the engine rebuild!

Al.

Before you dismantle your engine, you could determine the existing compression ratio.

Support engine so that a spark plug is at the highest point. With a piston at t.d.c. and both valves closed, fill the cyl. with light oil/paraffin etc up to the spark plug hole. Note the amount of fluid used. (= clearance volume) Drain the oil used.

Rotate the crankshaft so that the piston is now at b.d.c. with both valves closed (you might have to back-off the valve adjusters or remove the rocker shaft to ensure this). Refill the cylinder with oil etc to reach the spark plug hole. Note the amount of fluid used (=clearance volume + swept volume)

Divide the 2nd amount by the 1st amount., this gives you your C.R. no.

Compression Ratio = (Swept volume + Clearance volume) divided by Clearance volume

From these figures you can calculate the effect on C.R of using different thickness head gaskets. You might also be able to calculate the effect of milling different amounts from the cyl. head face.

When you remove your old head gasket, don't toss it away. Measure it's thickness, so you'll know what the thickness of a composite is when installed.

Good Luck with the engine rebuild!

Al.

Last edited:

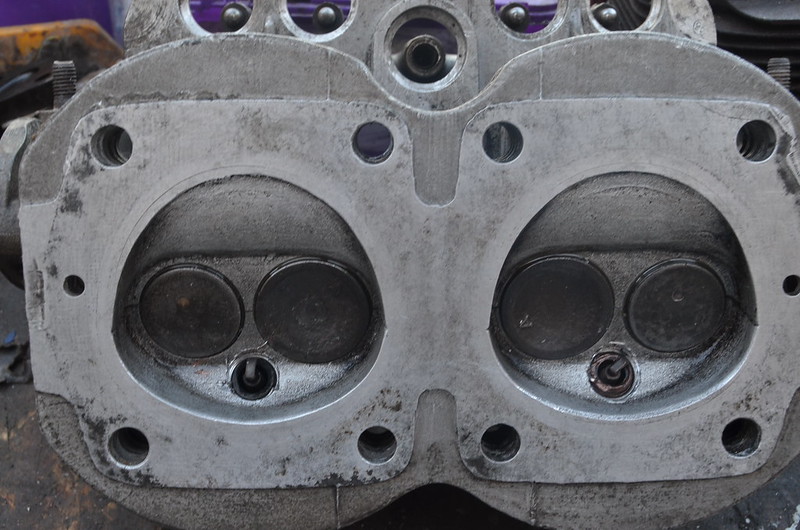

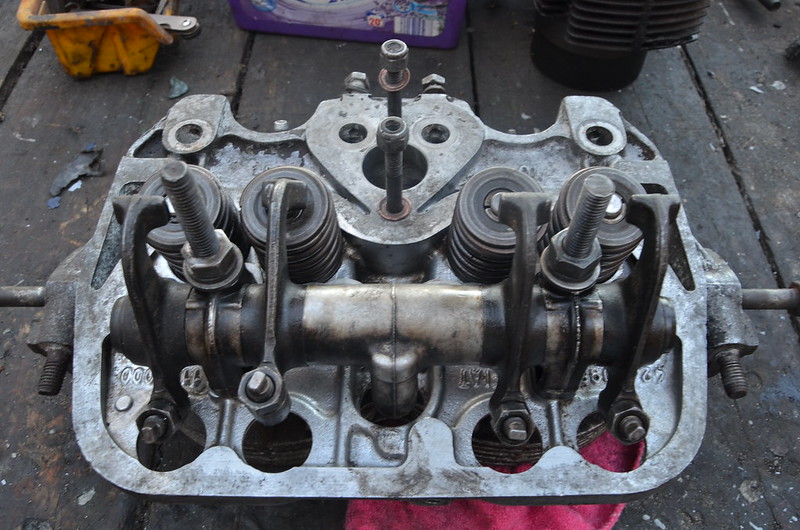

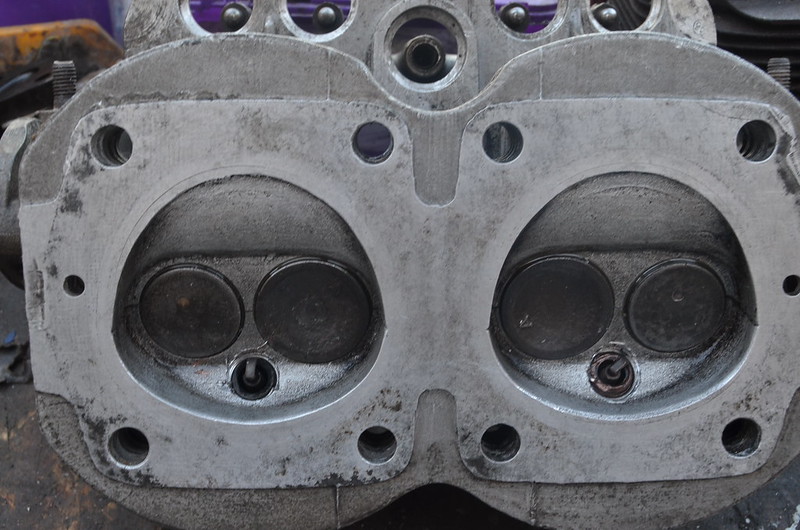

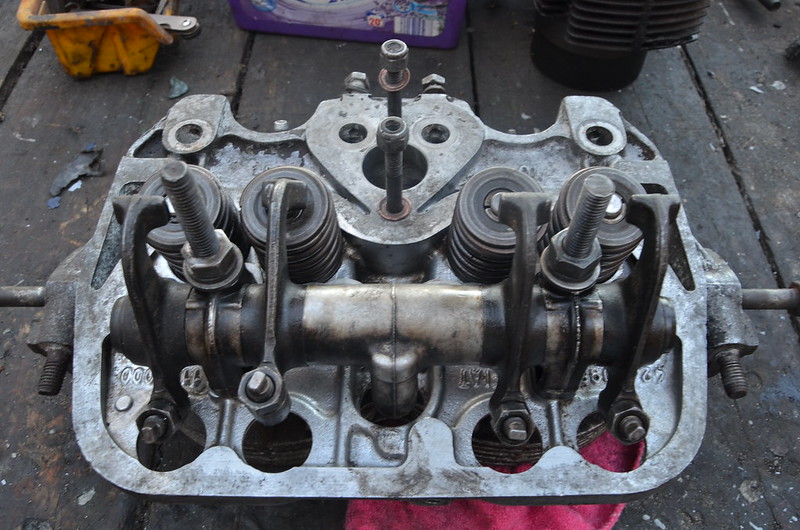

I was thinking of you today Thomas gordinir8. I have been re-assembling the 499 engine which had the valve problem about six weeks ago; I hate to leave things gathering rust. So just a couple of photos to show the head.  MAL_7826 by Peter Thompson, on Flickr

MAL_7826 by Peter Thompson, on Flickr MAL_7824 by Peter Thompson, on Flickr

MAL_7824 by Peter Thompson, on Flickr

The engine ran well apart from this head issue and although I tried not to dislodge the barrels, they did move:bang:. I was trying to put minimum effort into this, so as I didn't want to remove the pistons I extracted the old cylinder base gaskets and used my famous Permatex sealant to make gaskets in-situ. While I was at it I helped the seals on the concertina tubes with a smear of the same stuff. I try to arrange the tubes so that at the top the oil drain slots are all at the same orientation so that each cam-follower gets the same chance of lubrication. I have noticed that No. 3 or 4 cam-lobe always shows the most signs of wear. This was so in this case as they all looked brand new with the original machining markings showing except for number 4, which had some very fine pitting but was still shiny.

I was paying attention to gasket thickness, which was really the justification for offering these observations here. The head-gasket I removed measured at around 1.2mm on the tiny, uncompressed section in the middle. The brand-new, original Fiat gasket, which was actually designated for the 594 engine, measured 0.9mm. It was otherwise dimensionally the same, so I've increased my C/R.

The head-tightening sequence is wierd and I must have made about 15 passes on the nuts before they all settled-down to torque.

Ill get the engine running later in the week and so I'll have the next spare waiting just in case.

MAL_7826 by Peter Thompson, on Flickr

MAL_7826 by Peter Thompson, on Flickr MAL_7824 by Peter Thompson, on Flickr

MAL_7824 by Peter Thompson, on FlickrThe engine ran well apart from this head issue and although I tried not to dislodge the barrels, they did move:bang:. I was trying to put minimum effort into this, so as I didn't want to remove the pistons I extracted the old cylinder base gaskets and used my famous Permatex sealant to make gaskets in-situ. While I was at it I helped the seals on the concertina tubes with a smear of the same stuff. I try to arrange the tubes so that at the top the oil drain slots are all at the same orientation so that each cam-follower gets the same chance of lubrication. I have noticed that No. 3 or 4 cam-lobe always shows the most signs of wear. This was so in this case as they all looked brand new with the original machining markings showing except for number 4, which had some very fine pitting but was still shiny.

I was paying attention to gasket thickness, which was really the justification for offering these observations here. The head-gasket I removed measured at around 1.2mm on the tiny, uncompressed section in the middle. The brand-new, original Fiat gasket, which was actually designated for the 594 engine, measured 0.9mm. It was otherwise dimensionally the same, so I've increased my C/R.

The head-tightening sequence is wierd and I must have made about 15 passes on the nuts before they all settled-down to torque.

Ill get the engine running later in the week and so I'll have the next spare waiting just in case.

So is that the same head you had the valve seat issue or another one from you vast stock?

Yes, I do fear becoming like that old chap the other week who had a pile of Fiat junk to dispose of quickly. I just wish I still had the really vast stocks I had in the early '80s which would be very useful and valuable today; I must have scrapped/dumped it all but I can't remember.

Yes...the head is actually off the "boat anchor" of the yellow car; just the valves etc. as found, but obviously tidied up and with new valve-springs. I'm hoping for at least another 16,000 miles out of it as the pistons/bores are still in excellent condition.

I really like the 650 engine/box but definitely prefer the experience of the original so would like to put it back. I also need to have a good look where the bigger engine is leaking a little and I would like to have another go at the gearbox because the final drive is noisier than I would like. Both the items were totally unknown and very decrepit when I bought them so it still seems amazing to me that they have come back from the dead and taken me about 700 miles so far.