I am not dead sure but Fords with similar fitting screwed into the bearing housing/suspension hub and didn't have a separate carrier which is cheaper to replace.

I had to repair one on a Ford Focus I think, it was some years ago and it involved a thread insert kit and a new slider pin as cheaper than a suspension unit.

As

@jackwhoo says a photo of yours will be more use, possible a few on any carrier if it has one also.

My Ibiza had this setup and I'm disappointed to see my new Scala has the same:

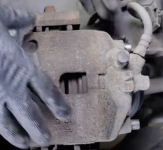

However it is what it is and you just have to work with what's there. For those not in the know the aluminium silvery coloured thing with Mando written on it is the brake caliper and if you look at it's bottom edge you can see the rubber guide with a wee black cap? If you remove that cap it exposes the end of the metal guide pin which has a female hex which you use an allen key to undo - usually a 17mm. Look right at the top of the picture and you can see the other one. Both pins need to be removed to free the caliper which can then be pulled forward off the hub assy/guides. The big "lump" of darker coloured metal underneath the caliper is all part of the hub/upright assembly and the caliper guide pins on this design screw directly into this casting. Some designs these pins screw into a separate casting called a caliper carrier which itself is then secured to the upright casting with some quite substantial bolts. I prefer this design because if the threads get damaged you can replace just the carrier The above design presents a problem because if the threads in the carrier get damaged beyond repair you are potentially faced with replacing the entire upright at enormous cost compared to the cost of a separate carrier.

I had exactly this problem on the Ibiza when I went to remove the N/S caliper slider pins at the end of it's warranty - so it was at that time 4 years old. I doubt very much if the garage would have removed the pins at any of the previous 3 services - which was supported by the fact I had a hell of a time getting the wheels off due to hub corrosion between the alloy wheels and steel hubs. But I wouldn't have expected them to have done it as it's not listed on the service sheet, just "check wheel nut torque". As I undid the bottom pin on the N/S it was feeling rather too "tight" for my liking but it had to come out so - However as I proceeded I was "terrified" by the sight of a thin thread of metal winding itself out of the hole with the pin! It's my belief the pin had been installed cross threaded at the factory, can't think how else this could have happened. The pin itself was absolutely fine, threads seemed undamaged but I wound a die down it anyway. After doing the usual, cleaning up the carrier, glaze busting the pads and applying some ceramic anti seize as needed (standard yearly service regime in other words) I wound a tap into the hole in the upright and managed to get the pin to wind back into the hole. it actually tightened up quite well and I put some thread locker on it too, but I wasn't happy about it so I rang one of the VAG specialists I know and asked if he could rethread it for me. Sorry pal, said he, we wouldn't do that on something so safety critical, but we'll change the upright for you. I didn't even bother asking how much that would cost!

So I rang another VAG specialist, actually nearer home, and he said "just bring it round tomorrow" So I did. He showed me their insert kit:

https://www.lasertools.co.uk/Product/5037/Brake-Caliper-Guide-Thread-Repair-Kit and explained how it's used. Told me it's a very common thing with this design of brake and they do a lot of them. He didn't even need to think of what it might cost just told me there and then £60 Pal. I thought that wasn't unreasonable (at that time I wasn't well known at this garage) so I told him to go ahead. Should be ready after lunch he said. The chap in charge was a very approachable fellow so I asked him what's involved and he showed me the whole procedure on another car he had up on a lift. The stepped drill enlarges the stripped out hole and sets a step on one side which you then press one of the threaded inserts into and "Bob's your Auntie"! Here's the hub/upright on my Ibiza, you can see there's no separate caliper carrier:

And here's a close up of that repair insert:

In fact he didn't drill the hole quite deep enough, that flange is supposed to sit in the casting but he didn't drill the hole quite deep enough. The pin screws in from the left side though so there's no chance of the insert falling out but the slider pin wasn't able to "grab hold" of quite as many threads as it might. You can see here from the other side how the insert could have been sunk further into the casting:

Unfortunately I didn't discover this until a year later when I next serviced the brakes and actually it held fine - and continued to do so for the next 5 years as long as I owned her - I just couldn't be bothered to go back and complain. The Laser kit is quite expensive but there are much cheaper copies by Neilsen, Bergen, etc, etc:

https://www.ebay.co.uk/itm/204183035654?itmmeta=01HSPE3D50MCHR8CHF78NJAES1&hash=item2f8a41df06:g:zzEAAOSwxztjlkHk&itmprp=enc:AQAJAAAA8O3GIIJ2D1XrmBNfmlNhd89YC1rye8KeRnQXA8zWaxTS/poZQUDu2D+Hig6gQzTbC8FJp3XpN3+Y9lnipeAFrRoUZ1arePInR6zTNOYgk0trKkBNJHh5IL3XDzEShMTwEv539rD732nZLcb/VsdM+Y9ApC4Mwan3X2k1aVxZ6P9qQnuAiidLUCHmetQNLg8ZEkMde3Kfuk2D7nHag0EDLcLeS3L71l2ruyiyIRzgoA6ZO9hv3nBXcy+djEOkb/nHbGlQKLlzzbSqZTGIfIhKmIOpL94HjYNdc4Nm4a+4WX3okLyoSIW0wF6RfcIS8hly6Q==|tkp:BFBMytKNzs1j which, if this ever happens again I would buy and just do the job myself.

The reason people have problems with these is that the pads are fitted to the caliper first. The inner pad has large spring "fingers" which go inside the hollow piston and the outer pad has retaining clips, very strong retaining clips, integral with the pad, which secures it to the outer fixed side of the caliper. The entire, pre-assembled caliper and pads is then fitted over the disc and secured with the two slider pins. The problem is that the retaining clips/springs/whatever you want to call them, tend to prevent you from easily lining up the pins with their threads and so it's easy to get a cross thread situation. I found it makes installation quite easy if you offer up the caliper assembly so that you can install one pin first - I went for the top pin - and when that one is crewed well home you can stick a large screwdriver into the inspection hole in the front of the caliper and easily lever the caliper down and in towards the disc until the bottom slider pin is nicely lined up. Only ever start the pins off with "finger power" until you're sure the threads are fully engaged. Once I evolved this way of doing it I never had a problem getting the threads to engage cleanly without cross threading. a wee bit of thread lock if you like, just to give peace of mind!

Sounds to me very much as though your threads have been completely stripped which would explain what you're describing. If that was the problem with mine I could have removed the disc and used a punch on the end of the slider pin thread to punch it through the, probably now ruined? threaded hole in the upright. If the pin is just spinning in it's hole the thread must be completely stripped? On the other hand the rubber guide on the other end is quite easily deformed and you might be able to get something like a Mole grip on the other end of the pin and pull it out of it's guide? The beauty of this repair system is that it can cope with threads which have been completely ruined - and looking at it, I think, that if you, at some time in the future, stripped the threads in the insert you could probably carefully, so as not to crack the hub casting, simply punch out the insert and press a new one in?