Stage 1 completed with the box stripped down,. During the course of this, one of my balls dropped I thought I found it but then realised that there is a fourth ball bearing which holds the speedo drive gear in place.

I thought I found it but then realised that there is a fourth ball bearing which holds the speedo drive gear in place.

I've rebuilt a BIS box before, so this stage doesn't phase me although there are a lot of bits that need cleaning and checking. But it seems that the main expenditure will be on the 1st/reverse kit, whih is currently on offer at Axel Gerstl. The trouble is that these days, 150 Euro means almost £150.

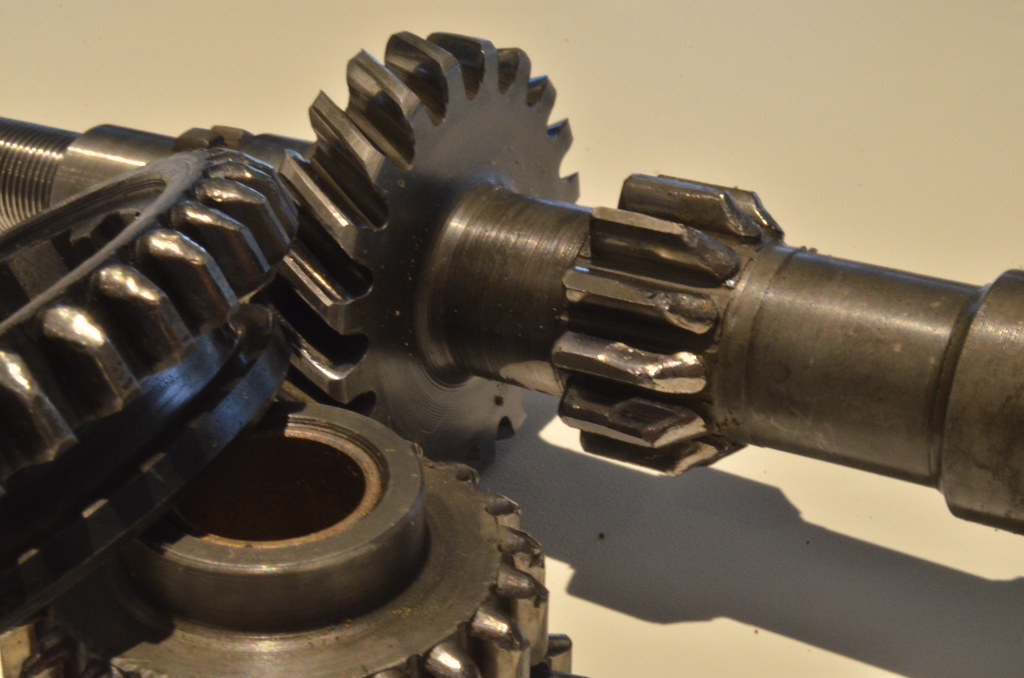

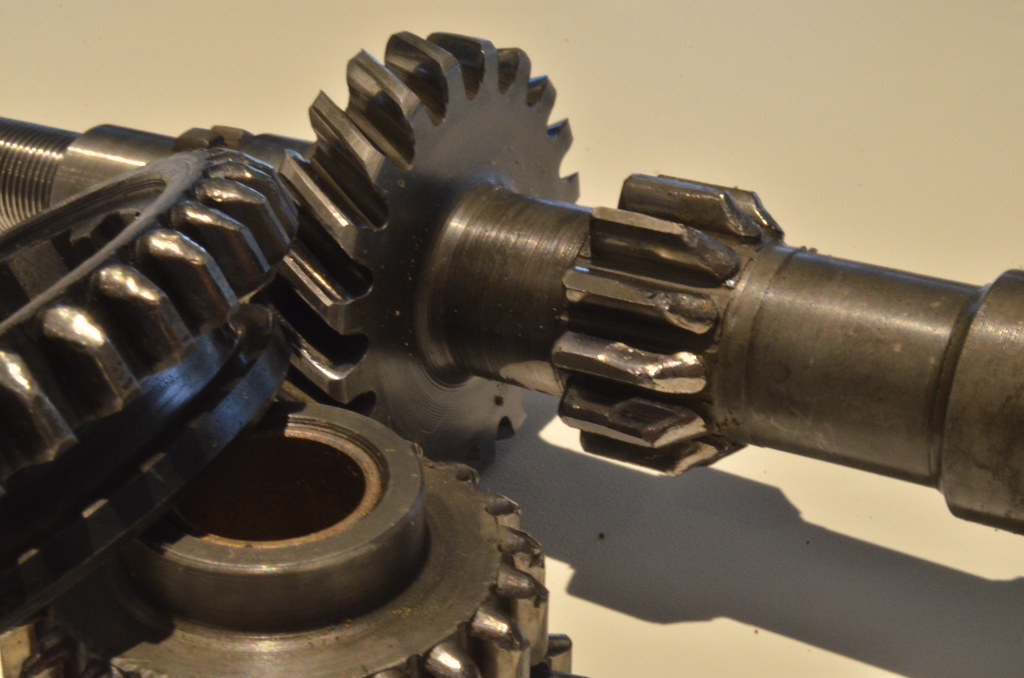

MAL_4246 by Peter Thompson, on Flickr

MAL_4246 by Peter Thompson, on Flickr

I've rebuilt a BIS box before, so this stage doesn't phase me although there are a lot of bits that need cleaning and checking. But it seems that the main expenditure will be on the 1st/reverse kit, whih is currently on offer at Axel Gerstl. The trouble is that these days, 150 Euro means almost £150.

MAL_4246 by Peter Thompson, on Flickr

MAL_4246 by Peter Thompson, on Flickr