Re: 2004 244 2.8JTD

I've transplanted the engine and all the electrics associated with the ECU and the main fuse box together, never been disconnected.

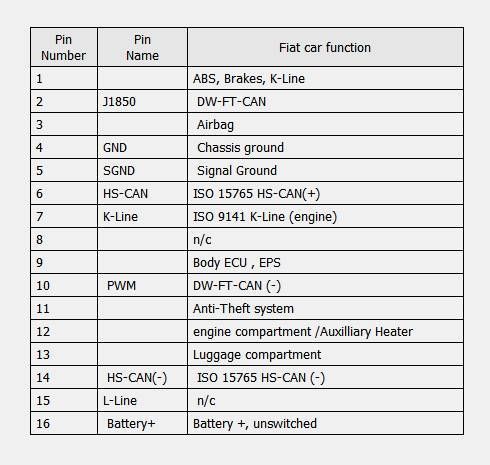

Before i proceed can anyone tell me the minimum required to start and run the engine?

Is there anything outside of the engine management that if missing or disconnected will prevent the engine from running?

For example, what is required to allow the fuel lifter pump to work?

Does the inertia switch need to be connected for the engine to run?

I already have the ignition/immobiliser connected.

Thanks for any help.

I've transplanted the engine and all the electrics associated with the ECU and the main fuse box together, never been disconnected.

Before i proceed can anyone tell me the minimum required to start and run the engine?

Is there anything outside of the engine management that if missing or disconnected will prevent the engine from running?

For example, what is required to allow the fuel lifter pump to work?

Does the inertia switch need to be connected for the engine to run?

I already have the ignition/immobiliser connected.

Thanks for any help.

Last edited: