Pete145

Member

- Joined

- Jun 2, 2014

- Messages

- 288

- Points

- 85

Hi everyone,

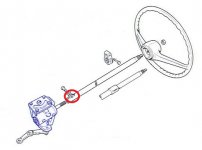

I'm pretty sure this will be very easy, but before I start attacking the steering wheel I thought I'd better check.

Since I took delivery of my 1971 L, one of the things that has irritated me is the position of the steering wheel, as it's sitting about 30 degrees off centre (rotated to the left).

This is particularly irritating as it interferes with the indicator de-activation on the steering column.

Is someone able to give me a step-by-step fix it guide, as this isn't covered in the Haynes manual? I assume it's just a case of taking off the horn button, loosening it and repositioning it, but I thought I'd check!

Pete

I'm pretty sure this will be very easy, but before I start attacking the steering wheel I thought I'd better check.

Since I took delivery of my 1971 L, one of the things that has irritated me is the position of the steering wheel, as it's sitting about 30 degrees off centre (rotated to the left).

This is particularly irritating as it interferes with the indicator de-activation on the steering column.

Is someone able to give me a step-by-step fix it guide, as this isn't covered in the Haynes manual? I assume it's just a case of taking off the horn button, loosening it and repositioning it, but I thought I'd check!

Pete