Hi Mark,

Oops, sorry I didn't reply earlier, but didn't have much to add to what jjhepburn said (the post was possibly

https://www.fiatforum.com/showpost.php?p=321529&postcount=7 by the way)

Usually it IS the switches that are faulty. They have solid-silver contacts, and should be fantastic, but somehow they are not.

What you can do is to install relays within the doors themselves, wired with a direct power feed to ensure full voltage to the window motors. Reliability is greatly improved this way, as the switch only has to supply the low current to turn the relay on.

The wiring is initially very confusing at the switches, but much simpler if you work from the motor backwards. The motor has just two wires, and obviously the polarity reverses, to reverse the direction of the window travel.

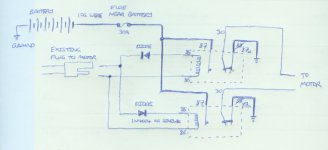

So, taking those two wires to the motor, you need to arrange two relays (for each motor). Each relay will have the coil connected across those two wires, BUT with a diode (1N4004, 1N4007, or similar) in series, so that the relay only works when the polarity is around one way. One relay will have the diode around the other way compared with the other relay. So, one relay 'clicks' for 'up', the other relay 'clicks' for 'down'.

With that part done, you need to provide a constant 12V to both relays. The output of each relay is connected to one motor wire. The relay that is 'on' will thus provide 12V to one side of the motor. The relay that is 'off' needs to ground the motor, i.e. provide a connection to earth. So, the normally-closed contact of both relays need to be connected to ground (the door frame). This causes the motor to run in either direction, when either relay turns on. If both relays are off, both sides of the motor are grounded. If both relays are on (for some reason, faulty switch?), then both sides of the motor would be 12V and the motor would not run.

I've drawn a quick diagram (pen and paper

) to try and show this.

Note that you need two SPDT relays (single pole, double throw) for each door. 'Double throw' means that there is a normally-closed contact as well as a normally-open contact. The output is connected to the normally-closed contact when the relay is 'off', and to the normally-open contact when the relay is 'on'. This type is also called a 'changeover' relay. It has the terminals 30, 87, and 87a. The important thing is that it does NOT have two 87 terminals. Relays with two 87 terminals are SPST (single pole, single throw) relays: both 87 terminals become live at the same time, no contact is connected with the relay 'off'. These are useful for headlights but no use for this application, since we need to ground the motor with the relay that is 'off'. Hope this makes sense.

You could use two DPST (double-pole, single-throw) relays instead. Double pole means that each relay handles both of the motor wires (one pair being reversed) - which would complicate the wiring. Most double-pole relays are also double-throw, so there would be unused live contacts to accidentally short out, or confuse you. These DPDT relays are not common in the automotive world (and do not accept standard automotive terminals) but could be purchased from an electronics shop. Or, you could use four SPST (single-pole, single-throw) relays. Again, needless complexity.

So, try to get the right SPDT relays to make the job easy (note the picture attached showing the circuit on the side of the relay). Also consider buying some relay sockets with wires already attached - less connections to have to make!

Remember to use a fuse holder in your main 12V feed from the battery (usually at the connection block at the back of the engine bay, with the lid). It's important that this fuse is near the battery, before the wire passes through any metalwork (this prevents a risk of fire if the wire chafes anywhere, e.g. on the entry to the door). 30A blade fuse will be sufficient. 10 gauge wire is nice, but probably more than necessary. 10 gauge wire is the largest size that will fit in yellow crimp terminals! Otherwise, ensure the wire is at least as large as the two existing wires to the motor.

The quality of the power/ground connections is important: consider soldering, or buy a lever-action crimp tool (not the glorified pliers/wire strippers...

) The ground connection should be fitted with an eye terminal and clamped under a bolt against the door metalwork. Note that the ground wires can be quite short and tidy - only the 12V wire needs to enter the door through the existing grommet.

Before you fit relays, it would be wise to connect a source of 12V (e.g. a spare car battery) directly to the motor, to test it. You may also like to measure the voltage available at the motor's connector with the motor turned on. I have seen 8V or less available as standard, which is why the windows are so slow!

Taking the relay approach will certainly make an improvement to the electric windows - whatever else happens. You could just clean the switches and make do (like I have with my Turbo). You could also work back through the wiring, replacing the weakened sections near the door hinges that may have lost some of their strands. But it is actually easier to fit the relays and their beefed-up power supply; the only reason this would not have been done in the first place is a matter of cost

For the motor lubrication, I find it easiest to pull out the white plastic tube from the door cavity, which provides a path for the rack when the window is down, and raise it above the level of the motor, then spray in copious quantities of lithium spray grease while operating the window up and down. You could also use another oily-greasy spray lubricant - but don't use WD40 by itself, since this will not provide enough lubrication over a prolonged period. Silicone spray may be sufficient. Silicone is definitely useful for the window rubbers (but is a pain to clean off glass).

I've only seen one faulty motor, and that was because of lubrication with WD40 that caused something internal to fall apart. Then I tried to take it apart and fix it, and this is something I definitely don't recommend - all the balls fell out and it never ran again

Hope this helps, please ask if you'd like something clarified?

-Alex