Great progress

-Alex

-Alex

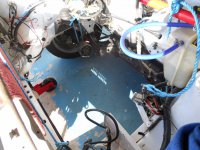

Cheers Dave. I work full time in an unrelated field, so I have learnt to plan large jobs during the week and do simple testing and other small jobs during the week in the evening. This normally means I know exactly what I'm going to do and have the parts ready to do what I want come the weekend.Excellent work LewisLooks like it was made for that engine bay.

If only I could move my projects forward at such a speed...

Cheers

Dave

This Uno is going to be a great drive... I'm sure the designers that used the T-Jet would have loved to have had it in a car as light as the Uno, rather than some 1250kg+ Bravo

Beautiful how you've fitted that engine in there.

Radiator fan is usually operational only with the car stationary and idling so I think it will be sufficient? Especially as it will be blowing air over the hot turbo too. Maybe some bonnet vents would help to get the hot air out - or perhaps some subtle vents through the inner wings into the front wheelarches?

-Alex

Lewey, you ARE da man! I`m loving it!

As soon as I can find a 1368 lump cheap enough, I will be putting it in my grey Uno, thats why I got the white Uno as my new runaround. I`m only aiming for 110bhp though! I`m sure I`m not the only one intending to do it either, so thank you for putting your progress on here, it`ll be very useful in future

Also, as Alex says, venting would help. I`d go for a full width front vent taking up air from directly behind the rad via an shroud behind the rad made of ally sheeting, maybe including the turbo in the airflow, similar to the rallying Lancias/Ford RS200 etc.

Are you keeping that standard air box?

very very good job u have achieved, well done.

dont forget to tell us about the performance after testing it.

Lewey, this is damn impressive.

You sticking with the stock ecu map or re-mapping?

Yes, I hope it delivers on it's promise of performance and reliability. I wish you luck with your alternative route. I thought I had a pretty mint shell until I saw yours!loving this project lewey. Its coming on brilliantly! Should be a great engine route that im sure many people will follow, not only in the uno world, but in other fiat models too.

need to crack on a bit more with mine! im onto the wiring and plumbing it in! we're getting there!