I received this question as a private message - I'm pleased to see it's been asked on the forum as well

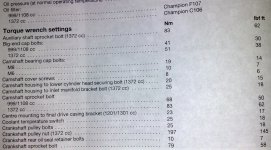

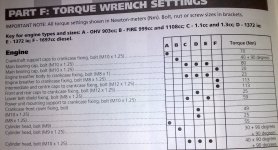

Personally, I only bother to use a torque wrench for certain very important bolts, such as flywheel bolts, big-end nuts, and suspension bolts. The tightest nut on the Uno is not the one behind the wheel (

), but the ones on the driveshafts - they are about 270Nm. And you expect that, because they're BIG. The torque is usually related to the diameter of the threads, except in a few special cases where the threads are hollow (like spark plugs, some sensors, certain special engine bolts, etc.)

Wheelbolts and other similar-sized 19mm-across-flats bolts/nuts are usually done up to 80-120Nm, which is easy to achieve with the length of the wheelbrace (not all that long).

For 13mm-across-flats nuts/bolts, I would just use a normal 3/8"-square drive socket spanner ratchet handle (which is about 20-25cm long) and I would do them up 'tight' with that lever, about the same as you would tighten the spark plugs to. That is up to about 40Nm.

For 10mm-across-flats nuts/bolts, I use a smaller 1/4"-square drive ratchet handle, which is only about 10cm long. 'Tight' with that smaller lever is not much torque, more like you would get when you tighten a nut with a ring spanner (the average ring spanner being about the same length as the small ratchet handle). This is probably about 10Nm. Torques for such small fastenings are not usually quoted.

When I look at a table of tightening torques, I'm always interested to see how they're all slightly different and many of them are surprisingly low. For example, a flywheel bolt being done up to the same tightness as a spark plug. In practice I think you will find that there's a wide 'tolerance' - the flywheel bolt could easily be done up to double the tightness and there would be no ill effect.

I look forward to seeing what other people say in the forum, I'm quite prepared to be wrong on this

EDIT: Thanks a73uk for providing the official answers!

-Alex