After being out of action for the last seven weeks and before I return to work I'm now wanting to get moving with Pandani's restoration. There's not much needing done except replacement of the rear suspension for the MOT in order to get it road legal again.

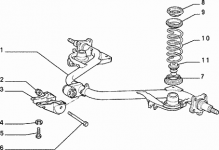

I had bought a new axle and dampers etc. about six months' ago and now have the remaining parts on order which should be here next week ready for my mechanic to replace. However, my he is reluctant to carry out the work until I can also obtain the piece of bent steel that is welded to the side of floor pan's box section, onto which the top of the spring and rubber cup is secured. The spring and its cup only cover about half of the the box section's underside and the remaining half of the spring and cup are supported by a piece of folded steel (a strip made up of 45° bends and approx 6" to 9" long) and it's this that needs replaced due to rot. I have looked at ePER and can't see the section of steel I'm referring to but I have suggested that we just replace it with a section of angle iron as it most likely is just part of floor pan and won't be available as a separate part, but he still is a bit reluctant.

Has anyone else had to replace this small section of steel and if so how?

I've tried about 15 times to upload photos but it just isn't working for me.

I had bought a new axle and dampers etc. about six months' ago and now have the remaining parts on order which should be here next week ready for my mechanic to replace. However, my he is reluctant to carry out the work until I can also obtain the piece of bent steel that is welded to the side of floor pan's box section, onto which the top of the spring and rubber cup is secured. The spring and its cup only cover about half of the the box section's underside and the remaining half of the spring and cup are supported by a piece of folded steel (a strip made up of 45° bends and approx 6" to 9" long) and it's this that needs replaced due to rot. I have looked at ePER and can't see the section of steel I'm referring to but I have suggested that we just replace it with a section of angle iron as it most likely is just part of floor pan and won't be available as a separate part, but he still is a bit reluctant.

Has anyone else had to replace this small section of steel and if so how?

I've tried about 15 times to upload photos but it just isn't working for me.