- Joined

- Sep 14, 2009

- Messages

- 19,899

- Points

- 3,413

My 100HP has always pulled left and I've just got around to sorting it. Two separate garages with laser alignment said it's straight (both rears 0 degrees on camber and toe angles) but the pull is still there and has got too annoying to ignore any more.

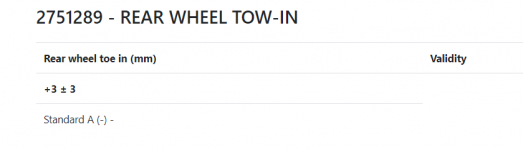

I was suspicious the back axle is mis-aligned by a couple of mm but could not get accurate measurements to prove it. The rear axle stubs bolt on to the axle frame. Shims under front or back mounts will alter the wheel toe or camber.

So the back end was jacked up, and I loosened the stubs axle nuts. Two layers of coke can material give 0.22mm of shim. Probably 0.2mm when compressed. The 15" wheels are 190mm radius so the mounting stud spacing will give about 0.7 mm of toe change. The car pulled left so I shimmed front of left side and rear of right side.

All back together agains, a test drive showed less pull, but still not as it should be. I added some 0.5mm aluminium shims to the 0.2mm already done. That gives about 2.5mm toe change at the wheel rim.

Result! The car now tracks straight. I could hallucinate that it's still a little more keen to go left than right, but it's not enough to worry about.

I was suspicious the back axle is mis-aligned by a couple of mm but could not get accurate measurements to prove it. The rear axle stubs bolt on to the axle frame. Shims under front or back mounts will alter the wheel toe or camber.

So the back end was jacked up, and I loosened the stubs axle nuts. Two layers of coke can material give 0.22mm of shim. Probably 0.2mm when compressed. The 15" wheels are 190mm radius so the mounting stud spacing will give about 0.7 mm of toe change. The car pulled left so I shimmed front of left side and rear of right side.

All back together agains, a test drive showed less pull, but still not as it should be. I added some 0.5mm aluminium shims to the 0.2mm already done. That gives about 2.5mm toe change at the wheel rim.

Result! The car now tracks straight. I could hallucinate that it's still a little more keen to go left than right, but it's not enough to worry about.