Introduction

Hi guys,

My first post except for introducing myself in the newbe thread

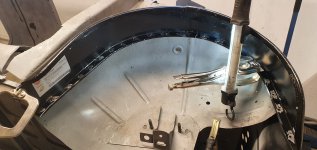

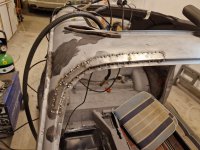

My 500F (my first 500) is in need ofa major restoration/rebuild. I´ve started small, removing doors and interior and cut out the right hand side floor board so far. The rust is far gone Some holes, but what is worse is that all the all surrounding sheet metal has serious surface corrosion. So mutch that I fear it´s to thin to be weldable. (Is that a word?)

Some holes, but what is worse is that all the all surrounding sheet metal has serious surface corrosion. So mutch that I fear it´s to thin to be weldable. (Is that a word?)

I have borrowed a jigg/cradle (or what it might be called in english) to suspend the car in, so that I can rotate it and don´t have to cut and weld om my back.

Now to my first question:

Where do I attatch the mountings in the front?

In the back I´ve seen pic´s online how to mount it. Has anyone here done this and have some pointers?

A few pics to lively up the post. (for some reason some pics gets turned, cant figure out why)

(for some reason some pics gets turned, cant figure out why)

My first post except for introducing myself in the newbe thread

My 500F (my first 500) is in need ofa major restoration/rebuild. I´ve started small, removing doors and interior and cut out the right hand side floor board so far. The rust is far gone

I have borrowed a jigg/cradle (or what it might be called in english) to suspend the car in, so that I can rotate it and don´t have to cut and weld om my back.

Now to my first question:

Where do I attatch the mountings in the front?

In the back I´ve seen pic´s online how to mount it. Has anyone here done this and have some pointers?

A few pics to lively up the post.