Introduction

Hi folks,

New member but long time lurker here. I have been on the hunt for a cinquecento for over 3 years now. Ive been a classic car enthusiast since i could remember and it was time to add some Italian flare to my overly German and American garage collection. I got the 500 bug for after servicing and enjoying a 500 that a friend of mine owns. I finally was able to get my hands on a 67 500F, and im overly joyed. I just finished a resto and full rebuild on a 75 911S, and kept on finding myself wanting to drive my friends Fiat over the Porsche. The Porsche is gone, and i needed to fill the empty void.

The car itself needs some TLC, and had been disassembled and partially sandblasted before "supposedly" its previous owner gave up on it. From my recollection, the car had not been on the road at all since it was brought in to Canada, and the engine had work done to it back in 92, more then likely back home in Italy. It is a bit of a basket case, as it has had some hackery done to it in its previous repairs. But its in safe hands now.

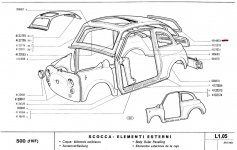

I am in the process of tallying all body panels needed (basically all lower panels, all fenders, all inner fenders, floor pans, etc the works. And slowly making a list of parts to order from the UK.

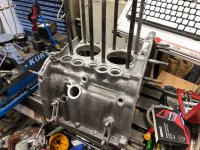

I couldn't wait to dig into the engine, and was able to clear a bench to start the tear-down process. The motor had a 540cc 70mm cylinder upgrade done to it in its past life, but had also seen some abuse. The cyl and pistons are in great shape, but the tappets and case cam holes need R&R, i ordered some C932 bronze stock, and will be machining insert sleeves for the cam. I plan to do some port/polishing and tweaking to this 540. I have forged 118mm connecting rods on their way as a "safety" insurance, for the fun it will see.

In a few years im planning a trip to Italy, family friends have a summer home just a hr away from D'Angelo Motori, and i will definitely be visiting them for some more spice to add. Coupled with a 650 block that im sure is much easier to find overseas then here in Canada. But in the mean time im going to enjoy the original 500/540 block to its full potential.

The car itself is an original F, someone had changed the front sheet metal in its early life. I will be restoring it back to its formal mustache glory. The car was originally "453 Medium Blue". I am leaning more towards keeping a blue, but going with more of an aqua marine shade. I have a paint sample "Frozen Blue K5J " from the 2018-2020 Porsche Taycan. Its a very mild metallic/pearl. So should still keep with the "solid/classic paint style" with some added depth. Again this hasn't been set in stone, and might change as i progress with the resto.

New member but long time lurker here. I have been on the hunt for a cinquecento for over 3 years now. Ive been a classic car enthusiast since i could remember and it was time to add some Italian flare to my overly German and American garage collection. I got the 500 bug for after servicing and enjoying a 500 that a friend of mine owns. I finally was able to get my hands on a 67 500F, and im overly joyed. I just finished a resto and full rebuild on a 75 911S, and kept on finding myself wanting to drive my friends Fiat over the Porsche. The Porsche is gone, and i needed to fill the empty void.

The car itself needs some TLC, and had been disassembled and partially sandblasted before "supposedly" its previous owner gave up on it. From my recollection, the car had not been on the road at all since it was brought in to Canada, and the engine had work done to it back in 92, more then likely back home in Italy. It is a bit of a basket case, as it has had some hackery done to it in its previous repairs. But its in safe hands now.

I am in the process of tallying all body panels needed (basically all lower panels, all fenders, all inner fenders, floor pans, etc the works. And slowly making a list of parts to order from the UK.

I couldn't wait to dig into the engine, and was able to clear a bench to start the tear-down process. The motor had a 540cc 70mm cylinder upgrade done to it in its past life, but had also seen some abuse. The cyl and pistons are in great shape, but the tappets and case cam holes need R&R, i ordered some C932 bronze stock, and will be machining insert sleeves for the cam. I plan to do some port/polishing and tweaking to this 540. I have forged 118mm connecting rods on their way as a "safety" insurance, for the fun it will see.

In a few years im planning a trip to Italy, family friends have a summer home just a hr away from D'Angelo Motori, and i will definitely be visiting them for some more spice to add. Coupled with a 650 block that im sure is much easier to find overseas then here in Canada. But in the mean time im going to enjoy the original 500/540 block to its full potential.

The car itself is an original F, someone had changed the front sheet metal in its early life. I will be restoring it back to its formal mustache glory. The car was originally "453 Medium Blue". I am leaning more towards keeping a blue, but going with more of an aqua marine shade. I have a paint sample "Frozen Blue K5J " from the 2018-2020 Porsche Taycan. Its a very mild metallic/pearl. So should still keep with the "solid/classic paint style" with some added depth. Again this hasn't been set in stone, and might change as i progress with the resto.