Hello, my first post...

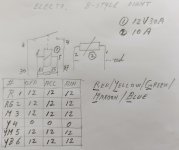

I would like to charge a series of LiFePO4 cells from the starter battery while driving. For this I use DC to DC converters which have a 30 Ampere rating and are fed from the starter battery. The question I have is how much current can I draw from the alternator, the starter battery. According to my information, there is a Valeo 200 A alternator in the car. A revision company gave me the tip never to put more than 60% permanent load on an alternator. That comes down to 120 A. Can someone tell me what the power consumption is under normal circumstances? So for example lights on, no air conditioning and other large consumers and a normally charged starter battery. Suppose that is 60 A, then I could reserve 2 * 30 A for DC to DC. Also important is how much current the alternator is charging the battery with. I hope that my question is clear.

Thanks in advance and my regards!

I would like to charge a series of LiFePO4 cells from the starter battery while driving. For this I use DC to DC converters which have a 30 Ampere rating and are fed from the starter battery. The question I have is how much current can I draw from the alternator, the starter battery. According to my information, there is a Valeo 200 A alternator in the car. A revision company gave me the tip never to put more than 60% permanent load on an alternator. That comes down to 120 A. Can someone tell me what the power consumption is under normal circumstances? So for example lights on, no air conditioning and other large consumers and a normally charged starter battery. Suppose that is 60 A, then I could reserve 2 * 30 A for DC to DC. Also important is how much current the alternator is charging the battery with. I hope that my question is clear.

Thanks in advance and my regards!