I am replacing the bottom ball joints on my y10 project. Have managed to get the old ones out but am struggling to get the new ones in.

Any tips?

Thanks

Any tips?

Thanks

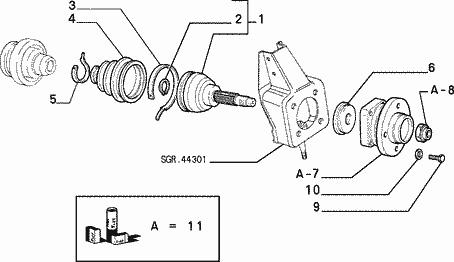

it would be easier to change the hub carrier and ball joint as one item. Ball joints such as these are notoriously difficult to change without the right tooling. These are not expensive (mine cost £18 from my local motor factor) and will save you a lot of blood, sweat and tears.

Erm... Don't be hard on me but I got mine off FIAT for 97 quid...

Please make me feel better and tell me that mine is 5 x better?

yeah you got a free plastic cover and a sticker with yoursErm... Don't be hard on me but I got mine off FIAT for 97 quid...

Please make me feel better and tell me that mine is 5 x better?

Jim

Spot on guys. Several options to try. As I have bought the ball joints already, I will try the forceful appoach. If that doesn't work then I will go for the complete hub units.

Cheers

Dave

you must use a press, dont try hammer or nothing like that, they will fall out when you are driving along

only if you are some kind of hammer happy animal, have persuaded them in before with the tapping from a hammer, all i'll say is dont be too heavy handed.