Hi

basics of using the Dipstick to check oil level ON ANY ENGINE

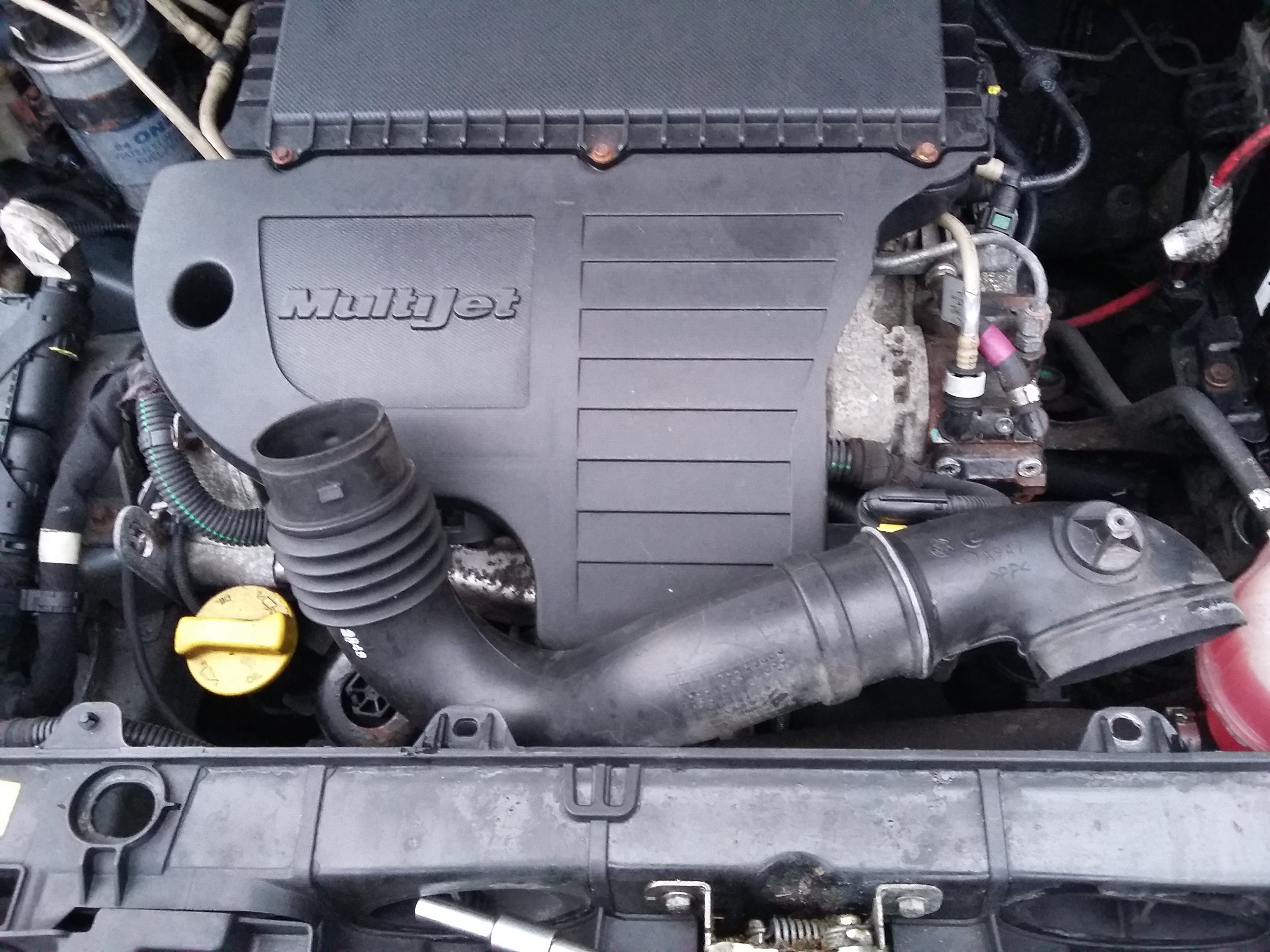

LOCATION

Often the Dipstick will have a coloured handle and be level in height with the engine cover

RED and Yellow are common..

TWINAIR are different ;-)

The Big YELLOW cap is where you ADD OIL

Traditionally the Dipstick will have a hook- crook handle and be at the top of a metal tube

Reading the dipstick :

You will want a CLEAN... and expendable.. piece of paper or cloth

With engine OFF and sat on relatively level ground

Withdraw the dipstick.. it will be OILY ;-)

HAVE A QUICK LOOK at the end furthest from the handle.. it may have an XXX crosshatching detail to hold oil

The oil should be visible on the cross hatched area.. there will almost certainly be a blob - drip of oil on the end

Take a 'mental note' of where the oil has covered.. and where it has not

Ok.. time for a more accurate reading !!

Wipe all the oil from that end of the dipstick.. then carefully insert it back in to get a reading of the oil level

My technique :

The dipstick is designed to be fully inserted..and when inserted fully it creates a seal ( keeps out dirt)

When sliding it in 'dry' ready for a reading of level

Stop 1inch - 25mm before the end of it

And slide it back out.. Look at the Hatching.. any oil ?

A drip on the end may not indicate the proper level.. but an oily mark up to a line in the hatching might ;-)

Slide it in now @ 10mm 1cm or 3/8" has a level appeared on the Hatched area..??

Ideally there will be SOME on the bottom edge

Now time for the 'By the Manual' method

With the dipstick wiped clean

Now carefully insert fully.. up to the seal..

Then withdraw

The oily mark should extend most of the way up the hatching.. BUT NOT BEYOND !

Twinair shown here ( its Beige colour plastic dipstick can be tricky to 'read' so I use Kitchen Towel.. and lay the dipstick along it.. the oil leaves a Brown mark on the white towel)

So : with an engine that has been standing for 10+ minutes..and on level ground

The level should show on the flattened / hatched area

If it doesnt appear..add 200ml of the correct oil at a time until it appears in your 5 minute interval dipstick checks

IF the level appears BEFORE the 10mm 3/8 short insertion point THIS COULD BE BAD

overfilled with ANY fluid isnt good

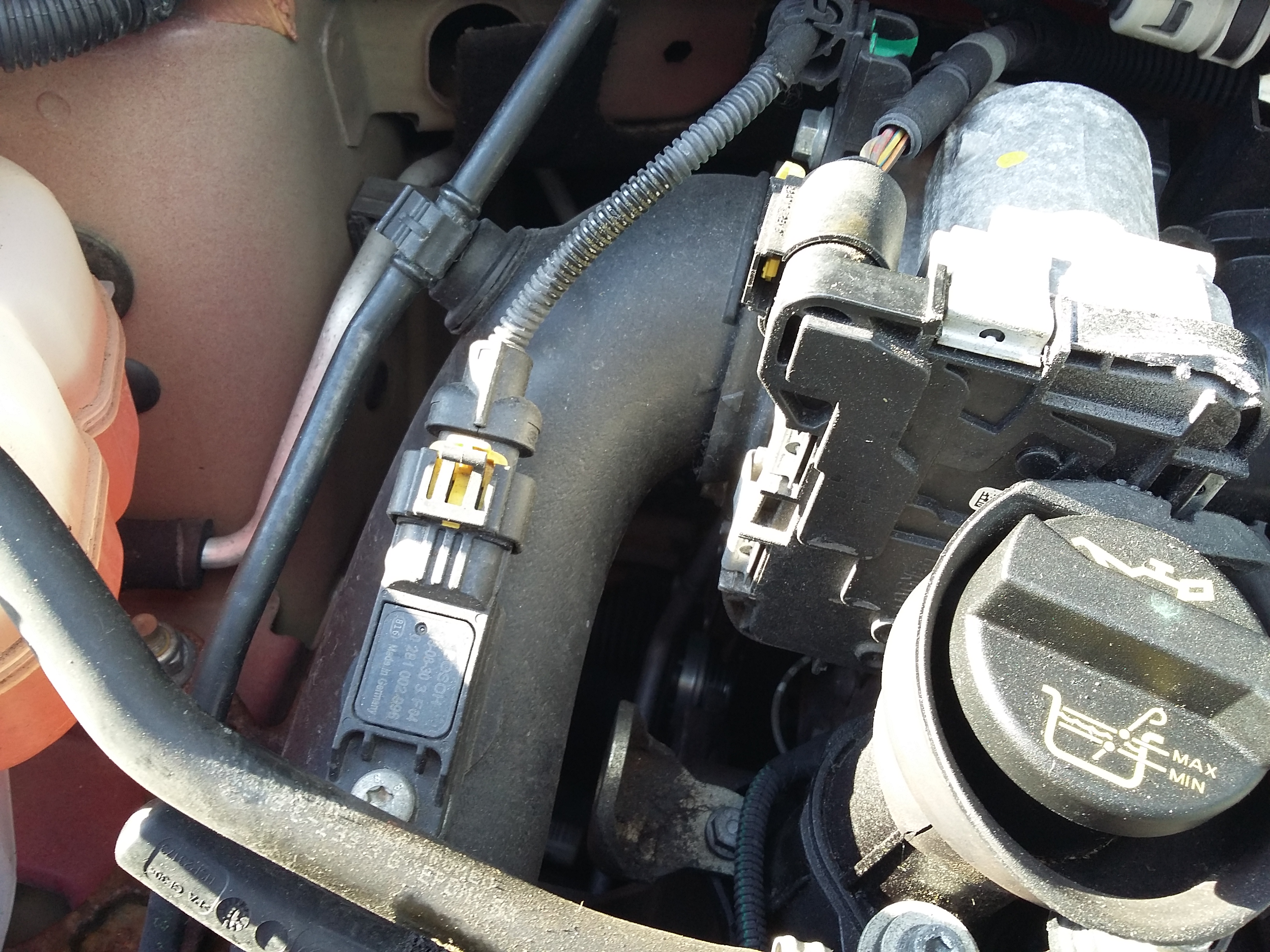

But in a DPF equipped diesel this could be an early warning of Big Problems

(Post on the Forum)

TWINAIR SPECIFIC INFO:

the twinairs have a combined oil filler cap and Dipstick

It is a Black cap..centre left of the main engine cover

It unscrews in a conventional way.. think of it as a 'bottle top'

Once unscrewed ..

CAFEFULLY lift the cap upwards

The plastic dipstick will slide out of the engine

Wipe it clean..and dip as above..

My Twinairs dont lose / use oil.. so show a level at 10mm short (SAT ON TOP) of engine.,

and nearly Full level when cap is SCREWED BACK INTO the engine

Caution:

1, The oilcap on the twinair can get really tight (forum members have broken theirs.) Just tighten it down 'snug'.. it needs no more to work

2, the dipstick can get brittle.. treat carefully

I sometimes feel it 'snag' as I lower it back into the engine.. I raise it up halfway and carefully lower it again

Once it goes in ok you can then tighten the cap

basics of using the Dipstick to check oil level ON ANY ENGINE

LOCATION

Often the Dipstick will have a coloured handle and be level in height with the engine cover

RED and Yellow are common..

TWINAIR are different ;-)

The Big YELLOW cap is where you ADD OIL

Traditionally the Dipstick will have a hook- crook handle and be at the top of a metal tube

Reading the dipstick :

You will want a CLEAN... and expendable.. piece of paper or cloth

With engine OFF and sat on relatively level ground

Withdraw the dipstick.. it will be OILY ;-)

HAVE A QUICK LOOK at the end furthest from the handle.. it may have an XXX crosshatching detail to hold oil

The oil should be visible on the cross hatched area.. there will almost certainly be a blob - drip of oil on the end

Take a 'mental note' of where the oil has covered.. and where it has not

Ok.. time for a more accurate reading !!

Wipe all the oil from that end of the dipstick.. then carefully insert it back in to get a reading of the oil level

My technique :

The dipstick is designed to be fully inserted..and when inserted fully it creates a seal ( keeps out dirt)

When sliding it in 'dry' ready for a reading of level

Stop 1inch - 25mm before the end of it

And slide it back out.. Look at the Hatching.. any oil ?

A drip on the end may not indicate the proper level.. but an oily mark up to a line in the hatching might ;-)

Slide it in now @ 10mm 1cm or 3/8" has a level appeared on the Hatched area..??

Ideally there will be SOME on the bottom edge

Now time for the 'By the Manual' method

With the dipstick wiped clean

Now carefully insert fully.. up to the seal..

Then withdraw

The oily mark should extend most of the way up the hatching.. BUT NOT BEYOND !

Twinair shown here ( its Beige colour plastic dipstick can be tricky to 'read' so I use Kitchen Towel.. and lay the dipstick along it.. the oil leaves a Brown mark on the white towel)

So : with an engine that has been standing for 10+ minutes..and on level ground

The level should show on the flattened / hatched area

If it doesnt appear..add 200ml of the correct oil at a time until it appears in your 5 minute interval dipstick checks

IF the level appears BEFORE the 10mm 3/8 short insertion point THIS COULD BE BAD

overfilled with ANY fluid isnt good

But in a DPF equipped diesel this could be an early warning of Big Problems

(Post on the Forum)

TWINAIR SPECIFIC INFO:

the twinairs have a combined oil filler cap and Dipstick

It is a Black cap..centre left of the main engine cover

It unscrews in a conventional way.. think of it as a 'bottle top'

Once unscrewed ..

CAFEFULLY lift the cap upwards

The plastic dipstick will slide out of the engine

Wipe it clean..and dip as above..

My Twinairs dont lose / use oil.. so show a level at 10mm short (SAT ON TOP) of engine.,

and nearly Full level when cap is SCREWED BACK INTO the engine

Caution:

1, The oilcap on the twinair can get really tight (forum members have broken theirs.) Just tighten it down 'snug'.. it needs no more to work

2, the dipstick can get brittle.. treat carefully

I sometimes feel it 'snag' as I lower it back into the engine.. I raise it up halfway and carefully lower it again

Once it goes in ok you can then tighten the cap