good progres arc should be good when finnished

wayne

wayne

Part Num. Qty. Availability Line Price Description

Manuf Part No

========= ==== ================= ==========

======================================== ==============

9760369 3 In Stock 5.79 IC, 8-BIT FLASH MCU;

Microprocessor/cont PIC16F628-04/P

1159699 1 In Stock 2.12 IC, STEPPER MOTOR DRIVER; Driver IC

type E-L6219

9712283 1 In Stock 2.95 CRYSTAL, 4.000000MHZ; Frequency,

output: LF A120A

1100369 5 In Stock 1.65 CAPACITOR, 22PF 100V;

Capacitance:22pF; SR151A220JTR

1100383 5 Awaiting Delivery 2.00 CAPACITOR, 0.1UF 100V;

Capacitance:0.1µF SR201C104KTR

1198320 5 In Stock 0.765 CAPACITOR, 47NF 100V;

Capacitance:47nF; ECQB1473JF

9339051 50 In Stock 0.60 RESISTOR, 0.25W 5% 1K; Resistor

element MCF 0.25W 1K

9497064 5 In Stock 1.65 RESISTOR, 3W 5% 1R0; Resistor

element ty W31-1R0 JI

1099879 50 In Stock 2.25 RESISTOR, 0.5W 1% 330R; Resistor

element MFR4 330R 1%

4142846 2 In Stock 3.04 RECEIVER, IR VERT LO POWER;

Wavelength, HIM702VM.

368106 10 In Stock 0.14 DIODE, HIGH SPEED DO-35; Voltage,

Vrrm:7 1N4148.

9692673 2 In Stock 2.00 CAPACITOR, 0.1F 5V;

Capacitance:0.1F; Vo EECS0HD104H

4701987 2 In Stock 3.08 EUROCARD PROTOTYPING BOARD;

Diameter, PC BP196

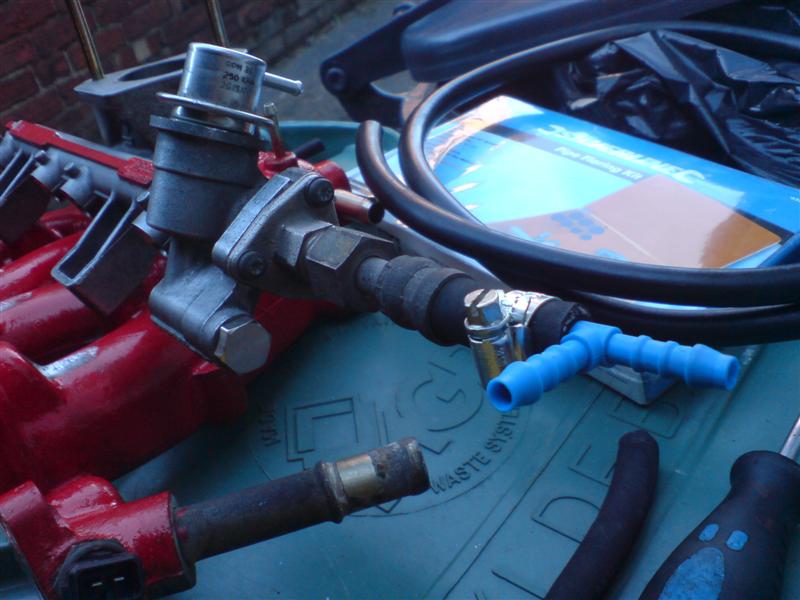

what about it.. should be metal? i said that to the bloke in the shop and he didn't agree.

what about it.. should be metal? i said that to the bloke in the shop and he didn't agree.

Well, I used to use that kind of stuff for non-pressurised systems. Does he know you're putting 3 bar through it?

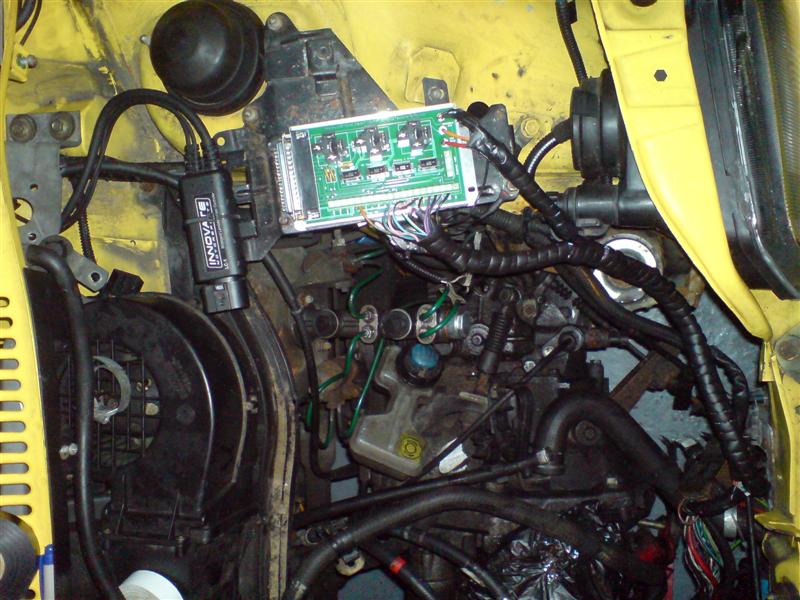

it is only the +ve, switched +ve and ground that are soldered. the rest are screwed into the terminal block. this is then cable tied to the ECU bracket. the cables are not being pulled on. like i say though, not finished. loom will be finished when the engine goes back togeter and can see wehre to route stuff.