Started to do it this evening, had bought the cheap timing kit on ebay, http://www.ebay.co.uk/itm/Fiat-Brav...325640?hash=item33ba7164c8:g:q5cAAOSw-KFXdQJ6

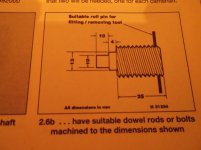

Tried to line up the cam shafts to screw in the locks and found they're too long, the grooved part will fit into the camshaft but the thread is too far back to screw in to get the tool to lock. Haynes has a guide to making the tool and you can see the difference in the pics, I'll mill it back tomorrow, I like things to work, just in case somebody thinks they haven't it set up right it would work fine to change the belt but the locks could shift. There is about 6mm to be taken off the ends and to mill out the flats to within 4mm of the threaded part. Is this the same on the other models it says it covers as well? Just giving the heads up to everyone.

Tried to line up the cam shafts to screw in the locks and found they're too long, the grooved part will fit into the camshaft but the thread is too far back to screw in to get the tool to lock. Haynes has a guide to making the tool and you can see the difference in the pics, I'll mill it back tomorrow, I like things to work, just in case somebody thinks they haven't it set up right it would work fine to change the belt but the locks could shift. There is about 6mm to be taken off the ends and to mill out the flats to within 4mm of the threaded part. Is this the same on the other models it says it covers as well? Just giving the heads up to everyone.

Attachments

Last edited:

This post contains affiliate links which may earn a commission at no additional cost to you.

![20170324_123849[1].jpg 20170324_123849[1].jpg](https://cdn.fiatforum.com/data/attachments/170/170131-bd1fbd6bdb180495cff5a606f95e586d.jpg)