Hello to all

I have a series 1 595 that's 2016 registered. bought with damage to the front so decided to get facelift bumpers and lights for front and rear.

Rear lights wired together with rear bumper no problem.

Front headlights straight forward in bolt on and plugin.

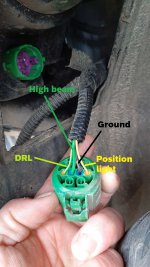

Problem I'm having is the day running lights working as intended. again it plugs in no problem however the led on new drls work only when headlights are on,

the incandesant dr lights are on when headlights are off. it should be the other way round. i suspect it maybe a relay causing this. Also dash warning light is showing a fault

Any guidance to resolve this, has anyone done this mod?

I have a series 1 595 that's 2016 registered. bought with damage to the front so decided to get facelift bumpers and lights for front and rear.

Rear lights wired together with rear bumper no problem.

Front headlights straight forward in bolt on and plugin.

Problem I'm having is the day running lights working as intended. again it plugs in no problem however the led on new drls work only when headlights are on,

the incandesant dr lights are on when headlights are off. it should be the other way round. i suspect it maybe a relay causing this. Also dash warning light is showing a fault

Any guidance to resolve this, has anyone done this mod?