- Joined

- Sep 5, 2021

- Messages

- 26

- Points

- 55

Thanks. Even with the hab battery out it wont start and also a very big drop in voltage to the ECU once it turns over.Hi,

May I respectfully suggest that the above may be in error. The 150A fuse pictured in post #1 is a cube fuse, and designed to be added directly to a stud on a battery terminal clamp, or sinilar location. I stand open to correction, but I am not aware of Fiat using this type of fuse at the battery fusebox (B099). The fuse 150A fuse (F70) is in the supply to the ignition switch, and if it was blown, both the starter motor, and the ECU would not be energised.

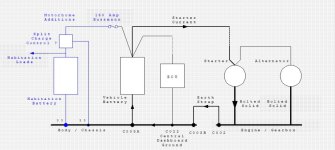

It is probable that the 150A cube fuse is the connection point for the habitation electrics, but 50A is a more typical value. If the split charge relay is of the voltage sensing type these seem to be rated at 120A, or more. If mains charging is applied before the voltage of the coupled batteries drops below the release voltage, then the batterries will remain coupled. This could explain the back feed from the habitation battery.

If I am understanding this correctly, starting was attempted with the starter battery disconnected. It is not surprising that the 150A cube fuse blew, if as previously suggested a voltage sensitive split charge relay remained operated.

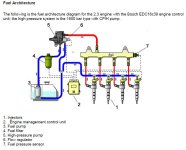

If the engine cranks at 150 rpm plus, the start failure is down to lack of fuel or air. One possibility is that the ECU is not being supplied with sufficient voltage to allow injection. As has been suggested by Anthony489, and others, it is worth eliminating the engine and starter battery earth connections.

With regard to the backfeed from the habitation battery, if the vehicle is fitted with a voltage sensing split charge relay, I suggest adding a control to this, so that the low current earth connection is controlled by a relay which is only operated when the ignition is on, or perhaps when D+ goes high.

I now don’t think that the two batteries are connected but that’s the alternator is charging the Hab battery when running.

Still perplexed how there was enough voltage with the starter battery completely disconnected to allow turn over…

I’ll great the electrical schematics from the manufacturer to too see how it is all linked up.