ruispeed3d

New member

Hi again guys,

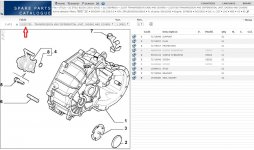

I was studying what flywheel and clutch pack to buy for my 2002 stilo jtd115 and as i was watching some fullpacks at the AUTODOC online store from VALEO i reached a dead end.

My VIN:ZFA19200000106018

They have two available FULLPACKS with the flywheel ref.55185864 that i pulled from Eper but both of them have a different clutch kit reference and also different clutch release bearing references.

The clutch kit reference i pulled from Eper (ref.55180163/55180276/55191330), for my surprise, is different from both of these packs. The clutch release bearing in Eper is shown with the reference SGR.21207 so i'm unable to compare it to the references from the packs.

Bellow are the two available packs in more detail:

VALEO 837005:

FULLPACK DMF

clutch release bearing: 804521

clutch kit: 826354

Flywheel: 836034

VALEO 837004:

clutch release bearing: 804524

clutch kit: 826353

Flywheel: 836034

All the references from both of these are apparently close to each other, only the last number being different, but still i cant reach beyond this point and it is killing me because i'm thinking how come i don't have any more information that allows me to choose one over the other.

If any of you could help me with this matter i would be very much appreciative.Other clutch suggestions are welcomed too, just take notice that i'm not from UK, i'm from Portugal.

Thank you in advance,

Rui Louro

I was studying what flywheel and clutch pack to buy for my 2002 stilo jtd115 and as i was watching some fullpacks at the AUTODOC online store from VALEO i reached a dead end.

My VIN:ZFA19200000106018

They have two available FULLPACKS with the flywheel ref.55185864 that i pulled from Eper but both of them have a different clutch kit reference and also different clutch release bearing references.

The clutch kit reference i pulled from Eper (ref.55180163/55180276/55191330), for my surprise, is different from both of these packs. The clutch release bearing in Eper is shown with the reference SGR.21207 so i'm unable to compare it to the references from the packs.

Bellow are the two available packs in more detail:

VALEO 837005:

FULLPACK DMF

clutch release bearing: 804521

clutch kit: 826354

Flywheel: 836034

VALEO 837004:

clutch release bearing: 804524

clutch kit: 826353

Flywheel: 836034

All the references from both of these are apparently close to each other, only the last number being different, but still i cant reach beyond this point and it is killing me because i'm thinking how come i don't have any more information that allows me to choose one over the other.

If any of you could help me with this matter i would be very much appreciative.Other clutch suggestions are welcomed too, just take notice that i'm not from UK, i'm from Portugal.

Thank you in advance,

Rui Louro

Last edited: