The sensor should be as close as possible without touching the ring. Usually a very thin spacer is used to set it up if it's adjustable

Can you do some electrical tests on the sensors?

SENSOR CIRCUIT CHECK

Ignition off- Set multimeter to resistance - check the sensor for continuity ie not a open/broken circuit

Disconnect the sensor connector and check the resistance across the two pins of the sensor.

No resistance = short circuit.

Infinitely high resistance = open circuit

Small resistance is good

ECU VOLTAGE INPUT

With ignition on check for voltage at one of the pins in the other connector coming from the car abs

No volts means no input is coming from ABS control unit and means the problem is upstream from the connector

If you have a voltage then the problem is at the sensor or in the return swignal line

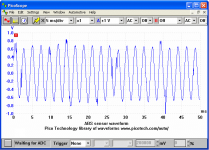

SENSOR OUTPUT SIGNAL

With ign on check for a fluctuating voltage at the other pin -the return signal line when you rotate the wheel

Fluctuating voltage is good and shows the sensor is working and picking up the wheel's signal

Nothing happening = the sensor or the tone ring are having problems and not communicating

These bearings really need to be fitted with a hydraulic press to keep the tone ring from damage.