PoorlyPunto

New member

- Joined

- Feb 14, 2021

- Messages

- 20

- Points

- 6

Hi all, this is my first post here!

I've got an mk2 Punto 1.2 8v that won't rev past 3000rpm. It started last week after not being driven for a few weeks. It starts and idles fine, and sounds smooth like it normally does but when I hold my foot on the accelerator it just revs up and down between idle & 3000rpm, the MIL light comes on and goes out once the car returns to idle.

I got RAC out who plugged their scanner in which read P0302 (misfire on cylinder 2), he changed the spark plugs and HT leads because they were very worn but it made no difference. He said the ECU had probably been spiked and needed replacement, he also said he was getting electric shocks from touching the engine bay before the spark plugs were changed. I had the car towed to a friend's house who knows more than I do about cars, he plugged his scanner in and got PO351/2 (ignition coils), the misfire code is no longer there. Both coil packs have now been changed and still no difference, the PO351/2 codes lingered and after a bit of research, it did suggest that this is a symptom of a failed ECU, so I placed an order on Friday for a remanufactured 'virgin' unit costing £120.

I've now got the registered version of Multiecuscan and the PO351/2 codes have disappeared (even though I don't recall clearing them) and no errors are detected. I've been looking at the data under the 'parameters' tab. Two things that stand out are: "Throttle position" gives a blank % reading, and "Phonic wheel status" changes to "faulty" when I rev the engine but returns to "OK" when the car is idling.

From reading other threads on this forum this seems to relate to the cambelt? I've tried to do the self-adaptation reset and phonic wheel learn reset but on all occasions it just said "conditions not suitable" or something similar. In hindsight though I think I may have been doing it wrong, I had warmed the engine up until the fan kicked in and then pressed "execute" on the procedures while the engine was running but I think I should have run the procedure first and THEN started the engine and let it warm up before revving to 5000rpm 3 times. Can anyone confirm?

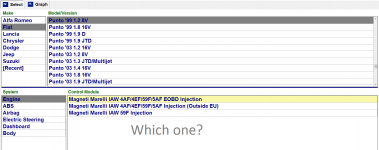

Also, before connecting to the ECU with MES, there are 3 different 'modules' in the list, and I'm wondering if I was connecting to different ones and if that would explain the error codes seemingly disappearing on their own without being cleared? I've attached some screenshots of the data in MES, the first 3 are with the car idling, the fourth is when I rev it and the fifth is the 3 'different' ECUs in the MES menu.

The new ECU is being delivered tomorrow but I'm really not convinced it will solve the problem. I'm trying to avoid installing it until other issues have been ruled out because once it's fitted to this car, I probably wouldn't get a full refund on it because it would have to be reprogrammed and "virginised" by the company before being resold. But with no other error codes being stored I'm not sure where next to go with this.

Can anyone offer any advice or share their thoughts?

Many thanks in advance!

Andrew

I've got an mk2 Punto 1.2 8v that won't rev past 3000rpm. It started last week after not being driven for a few weeks. It starts and idles fine, and sounds smooth like it normally does but when I hold my foot on the accelerator it just revs up and down between idle & 3000rpm, the MIL light comes on and goes out once the car returns to idle.

I got RAC out who plugged their scanner in which read P0302 (misfire on cylinder 2), he changed the spark plugs and HT leads because they were very worn but it made no difference. He said the ECU had probably been spiked and needed replacement, he also said he was getting electric shocks from touching the engine bay before the spark plugs were changed. I had the car towed to a friend's house who knows more than I do about cars, he plugged his scanner in and got PO351/2 (ignition coils), the misfire code is no longer there. Both coil packs have now been changed and still no difference, the PO351/2 codes lingered and after a bit of research, it did suggest that this is a symptom of a failed ECU, so I placed an order on Friday for a remanufactured 'virgin' unit costing £120.

I've now got the registered version of Multiecuscan and the PO351/2 codes have disappeared (even though I don't recall clearing them) and no errors are detected. I've been looking at the data under the 'parameters' tab. Two things that stand out are: "Throttle position" gives a blank % reading, and "Phonic wheel status" changes to "faulty" when I rev the engine but returns to "OK" when the car is idling.

From reading other threads on this forum this seems to relate to the cambelt? I've tried to do the self-adaptation reset and phonic wheel learn reset but on all occasions it just said "conditions not suitable" or something similar. In hindsight though I think I may have been doing it wrong, I had warmed the engine up until the fan kicked in and then pressed "execute" on the procedures while the engine was running but I think I should have run the procedure first and THEN started the engine and let it warm up before revving to 5000rpm 3 times. Can anyone confirm?

Also, before connecting to the ECU with MES, there are 3 different 'modules' in the list, and I'm wondering if I was connecting to different ones and if that would explain the error codes seemingly disappearing on their own without being cleared? I've attached some screenshots of the data in MES, the first 3 are with the car idling, the fourth is when I rev it and the fifth is the 3 'different' ECUs in the MES menu.

The new ECU is being delivered tomorrow but I'm really not convinced it will solve the problem. I'm trying to avoid installing it until other issues have been ruled out because once it's fitted to this car, I probably wouldn't get a full refund on it because it would have to be reprogrammed and "virginised" by the company before being resold. But with no other error codes being stored I'm not sure where next to go with this.

Can anyone offer any advice or share their thoughts?

Many thanks in advance!

Andrew

Attachments

Last edited: