- Joined

- Jan 20, 2013

- Messages

- 6,151

- Points

- 1,228

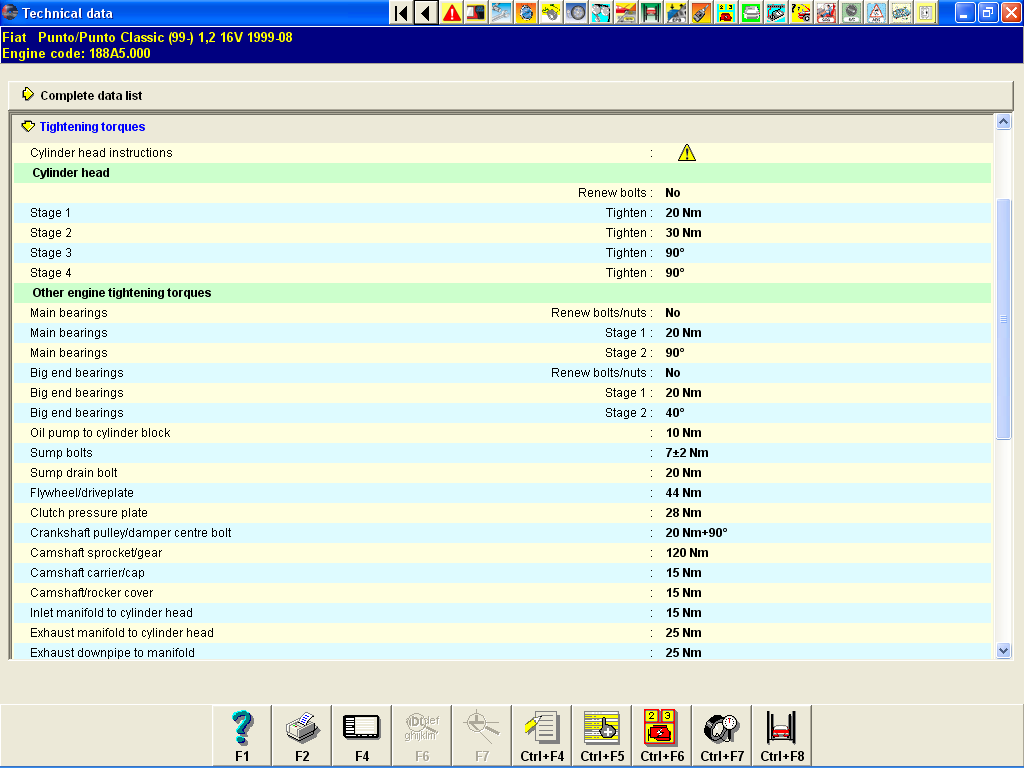

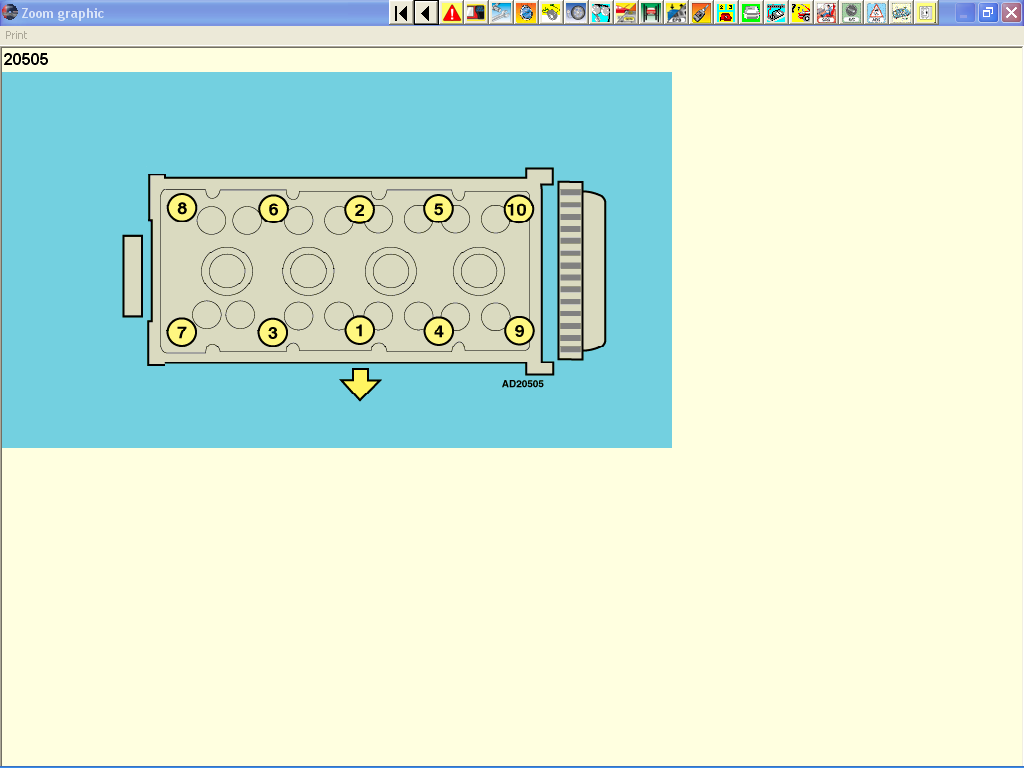

tightening 16v head

so i know the " torque" and tightening sequence, but is there anything else i should do before putting gasket on and torquing, should i use sand paper for block cleaning?

also that 90 degree torque, does it rly have to be tightened like that or is that just exaggerating

at what nm should i set my torque wrench

so i know the " torque" and tightening sequence, but is there anything else i should do before putting gasket on and torquing, should i use sand paper for block cleaning?

also that 90 degree torque, does it rly have to be tightened like that or is that just exaggerating

at what nm should i set my torque wrench

Attachments

Last edited: