A few years ago during the restoration of my 500F, I decided to build myself a 695cc engine and in doing so, replaced the Weber IMB carburettor with a Dell'Orto 32/28 FZD.

As far as I know, these carburettors were never standard equipment on any cars. They were manufactured as an after market item and used by tuners in the 60s and 70s on small 2 to 4 cylinder engines.

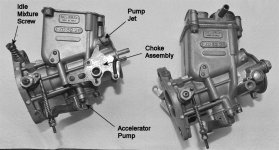

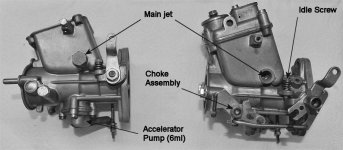

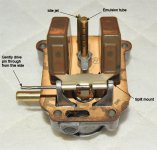

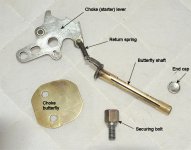

The FZD is a single throat design with a main butterfly and a inline secondary butterfly in the starting (choke) circuit.

It is a 'tilted sidedraft' carburettor with the main throat sitting 20 degrees up from horizontal.

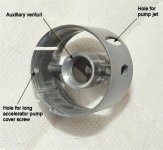

The main throat is either 30mm or 32mm in diameter fitted with a 24mm or 28mm removable auxilliary venturi respectively.

There may be other variations, but the 30/24 and 32/28 are the main ones.

Manifolds for the Fiat 500/126 engines are still commonly available.

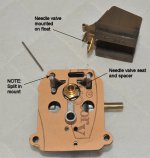

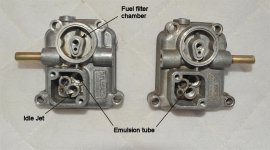

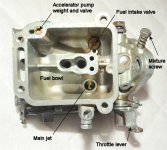

The main advantages over the IMB are the presence of an accelerator pump, a larger dual chamber fuel bowl which is much less prone to foaming, better thermal isolation with maybe easier hot starting and a larger variety of tuning components.

Disadvantages are relative rarity, price and availability of some components though this seems to be improving with at least two web sites offering a nice range of parts (www.dellortoshop.com/ and www.dellorto.co.uk/).

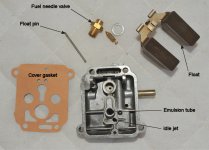

Rebuild kits are also available.

When I bought my FZD, I got a two for one deal though the second carby was missing several parts and had many stripped threads. In my excited haste to get my engine going I replaced a few gaskets, bolted on the good carby and started driving. I promised myself that I'd clean and service it one day. Well a couple of weeks ago that day came.

For no compelling reason other than a bit of spare time, I removed it, stripped it and rebuilt it. Along the way I took lots of photos which I'll attach to the next few posts.

I've also scanned what little information I have including my rough translation of the Italian text and attached the pdf to this post.

So here goes ...

Chris

As far as I know, these carburettors were never standard equipment on any cars. They were manufactured as an after market item and used by tuners in the 60s and 70s on small 2 to 4 cylinder engines.

The FZD is a single throat design with a main butterfly and a inline secondary butterfly in the starting (choke) circuit.

It is a 'tilted sidedraft' carburettor with the main throat sitting 20 degrees up from horizontal.

The main throat is either 30mm or 32mm in diameter fitted with a 24mm or 28mm removable auxilliary venturi respectively.

There may be other variations, but the 30/24 and 32/28 are the main ones.

Manifolds for the Fiat 500/126 engines are still commonly available.

The main advantages over the IMB are the presence of an accelerator pump, a larger dual chamber fuel bowl which is much less prone to foaming, better thermal isolation with maybe easier hot starting and a larger variety of tuning components.

Disadvantages are relative rarity, price and availability of some components though this seems to be improving with at least two web sites offering a nice range of parts (www.dellortoshop.com/ and www.dellorto.co.uk/).

Rebuild kits are also available.

When I bought my FZD, I got a two for one deal though the second carby was missing several parts and had many stripped threads. In my excited haste to get my engine going I replaced a few gaskets, bolted on the good carby and started driving. I promised myself that I'd clean and service it one day. Well a couple of weeks ago that day came.

For no compelling reason other than a bit of spare time, I removed it, stripped it and rebuilt it. Along the way I took lots of photos which I'll attach to the next few posts.

I've also scanned what little information I have including my rough translation of the Italian text and attached the pdf to this post.

So here goes ...

Chris

Attachments

Last edited: