- Joined

- Sep 14, 2009

- Messages

- 19,492

- Points

- 3,294

The clutch had become a bit judders when I needed to make a quicker than usual getaway, but no big deal. Then yesterday it was revving at motorway speeds like I had my foot on the clutch pedal. No judder just revving until I let off the power. So although the clutch at less than 40,000 miles old (and I'm not rough on clutches) is going to have to be replaced. Slave and master cylinders were changed when this clutch was fitted.

I've just crawled out from underneath the car -

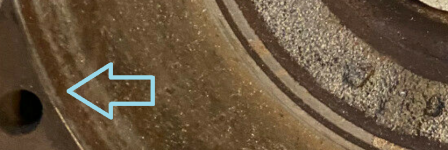

LHS gearbox output shaft seal housing is wet with oil which is odd because the seals were replaced last year. RHS is dry.

Gearshifter shaft is dry (seals replaced last year).

The clutch inspection cover on top of bell-housing is dry inside and bottom of bell-housing is dry. I need to borrow an inspection camera to look deeper inside.

I'm going to DIY the clutch and will be checking the gearbox bearings and seals. I will be talking to S4P tomorrow, but does anyone have tips for buying the gearbox input bearings and seals?

I've just crawled out from underneath the car -

LHS gearbox output shaft seal housing is wet with oil which is odd because the seals were replaced last year. RHS is dry.

Gearshifter shaft is dry (seals replaced last year).

The clutch inspection cover on top of bell-housing is dry inside and bottom of bell-housing is dry. I need to borrow an inspection camera to look deeper inside.

I'm going to DIY the clutch and will be checking the gearbox bearings and seals. I will be talking to S4P tomorrow, but does anyone have tips for buying the gearbox input bearings and seals?

Last edited: