Introduction

So this weekend has been a rather busy one. After an impromtu ebay purchase, me and the old man made three 180 mile round trips to Gloucester to retrieve three Sisleys in various states of neglect.

1 red H reg with 95k on the clock and 2 blue F regs with 60 and 65k on the clock.

All have been off the road for quite some time and there are no documents to accompany them, but at £600 i thought it was a bit of a steal.

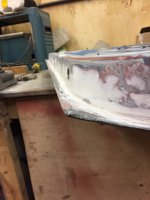

One of the blue ones has taken a nasty hit, and the sills are completely shot so the body is a no go. It still has the engine, gearbox and running gear. The other has a taken a shunt to the front left wing but with a strong amount of tlc could pass as a rough and ready green laner. With no gearbox and a pretty sad looking engine, i'll likely use the crumpled blue as a donor. Saying that all of the cars are non-runners and without having had a proper look im just speculating.

Now the red one is definately a feasible project, with 'fairly' solid sills and no major dents in the body work (despite the awful doors) she looks to be the bread winner of the lot. The inside isnt so 'wild' either.

The majority of the weekend has been spent loading, transporting and unloading, as well as cleaning out the garage for the new inhabitants so ive only managed to take a handfull of photos.

So the basic plan is to leave the red one for the time being, since she is the least desperate and doesnt look so much of an eye sore on the drive. My priority for now is to strip the blue without the gearbox and assess the body properlly to decide whether she is a keeper or not. If so ill be spending some time on the welder, scraping all of the broken bits and stripping the second blue for all of the useful parts (not keeping my hopes up though).

I'll try and keep the thread up to date with the work and have some more detailed pictures up next weekend after ive gone over the body with a screwdriver and hammer

1 red H reg with 95k on the clock and 2 blue F regs with 60 and 65k on the clock.

All have been off the road for quite some time and there are no documents to accompany them, but at £600 i thought it was a bit of a steal.

One of the blue ones has taken a nasty hit, and the sills are completely shot so the body is a no go. It still has the engine, gearbox and running gear. The other has a taken a shunt to the front left wing but with a strong amount of tlc could pass as a rough and ready green laner. With no gearbox and a pretty sad looking engine, i'll likely use the crumpled blue as a donor. Saying that all of the cars are non-runners and without having had a proper look im just speculating.

Now the red one is definately a feasible project, with 'fairly' solid sills and no major dents in the body work (despite the awful doors) she looks to be the bread winner of the lot. The inside isnt so 'wild' either.

The majority of the weekend has been spent loading, transporting and unloading, as well as cleaning out the garage for the new inhabitants so ive only managed to take a handfull of photos.

So the basic plan is to leave the red one for the time being, since she is the least desperate and doesnt look so much of an eye sore on the drive. My priority for now is to strip the blue without the gearbox and assess the body properlly to decide whether she is a keeper or not. If so ill be spending some time on the welder, scraping all of the broken bits and stripping the second blue for all of the useful parts (not keeping my hopes up though).

I'll try and keep the thread up to date with the work and have some more detailed pictures up next weekend after ive gone over the body with a screwdriver and hammer