hi guys

just changed the cambelt on my 1800 16v, went easy enough

but now its noisy from the exhaust valve side, runs a treat

i had been on a 300 mile run the day before, i had not started the engine before i changed the cambelt so i don't know if it was already noisy.

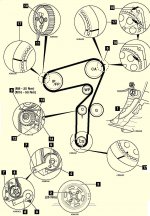

on both the cam shaft pulleys and the crankshaft (the shaft not the pulley)

there are marks/lines (normal thing you get to line up pulleys)

i lined the 2 camshaft pulley marks adjacent to each other and the crankshaft maft in line with the mark on the engine block

(as you would normally do on a ford or vauxhall)

anyone have any idea what could be wrong?

just changed the cambelt on my 1800 16v, went easy enough

but now its noisy from the exhaust valve side, runs a treat

i had been on a 300 mile run the day before, i had not started the engine before i changed the cambelt so i don't know if it was already noisy.

on both the cam shaft pulleys and the crankshaft (the shaft not the pulley)

there are marks/lines (normal thing you get to line up pulleys)

i lined the 2 camshaft pulley marks adjacent to each other and the crankshaft maft in line with the mark on the engine block

(as you would normally do on a ford or vauxhall)

anyone have any idea what could be wrong?