Hurrah! Found the soldering "stuff". It was hiding behind the box I keep my plumbing syphon in which is on top of the old fridge which got displaced from the kitchen when Mrs J got her new kitchen about 10 years ago. The new kitchen had to have a built in fridge which hides behind a cupboard door so looks like a cupboard, not a fridge. This means it'll be about three times the agro if I ever have to pull it out!

Anyway, back to the soldering stuff. I'd been at the old, long gone now, autojumble which was located in Portobello town hall. I would go every year and invariably came away with some useful stuff. On this occasion though I hadn't found anything I either didn't have something similar to or was too expensive or in too poor a condition to be worth acquiring. I'd noticed, early on, a box with what looked like a couple of soldering irons underneath a bench so not prominently displayed. Just out of "nosyness" I decided to go and rake through it before going home. When I pulled it out the chap on the stall said "This lot all goes together" and dragged out another home made wooden box - the irons were in a plastic box - and an old 110 volt transformer. "they're all 110 volt" he said, "so you might as well have this too if you want it". Here's the two boxes:

and the transformer - d'you like the handle? I made it myself!

"Does it all work" I asked. "As far as I know yes" he said, "but if you get it home and find it's junk then bring it back to the next jumble and I'll give you your money back". Naively I took him at his word and paid him. I think about £25? Not especially cheap - it was maybe 40 years ago - but not a fortune either if everything worked I thought.

Got it home and emptied it all out. There was a load of stuff in the wooden box. 3 rolls of multicore electric solder, some solid solder bar, corrosive solder flux, brazing flux powder, solder paste, tip cleaning sponges and more:

I was interested to see some de-soldering solder mesh. stuff I knew what to do with, but also a tube of DYNALU solder for soldering aluminium! and the wee black box of strip multicore solder, called "tape solder" Never seen "tape solder" before and never used the aluminium solder (still haven't):

Well, that's all looking pretty good. The fluxes and solders must be worth what I paid for the lot? Ok, what's in the blue box? I've layed it out so you can see:

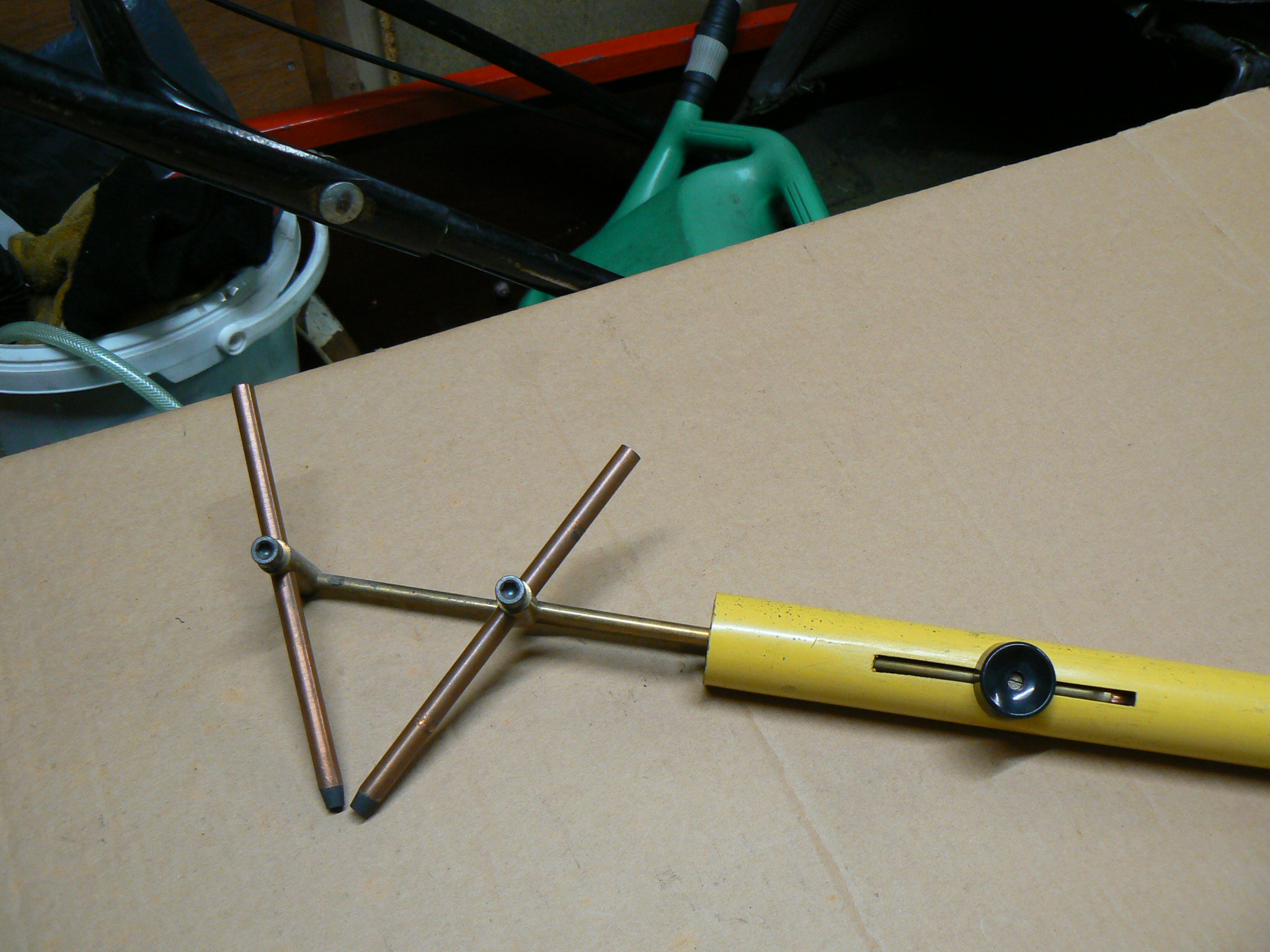

Wow! On the right are two, light blue, Weller (high quality stuff weller makes) temperature stabilized 60 watt soldering irons. Next, blimey what a big one, is a 200 watt soldering iron! then three flame heated irons, a bunch of strange copper coloured rods and a weird "contraption" with a yellow handle, on the left. I actually thought I knew what that last item was but I wasn't sure how you would use it.

The big question, of course, was, does any of it work? Would have been disappointing if non of it did but I was pleased enough with the supplies in the wooden box alone to have made the purchase worth while. The transformer actually was "bare" so I had to take the top off and wire a supply cable in - very simple and obvious when the top was removed. I plugged it into an RCD in my garage and was greeted with a nice steady growly hum. both the Wellers strted heating up when plugged in but the big black handled one didn't seem to be getting hot. I then went through to make a cup of tea and just forgot to turn the transformer off. when I came back, just minutes later, it was toasty hot! Whoo Hoo!

As you might imagine, I was absolutely cock-a-hoop with my bargain buy - but what about that yellow handled thing? Well, a number of years before that I'd bought a MMA welder (stick welder) here's a picture I posted a while ago when I was making a spare wheel retainer for the Mazda which shows it:

I remembered reading in the bumph that came with it that you could buy a brazing attachment as one of the optional extras but, as I had access to Oxy Acetylene I didn't look into it. I was pretty sure that's what this is. I wasn't really interested in it but my pal from up the road, the guy that taught welding at the local technical college, noticed it one day when he stopped by for a chat. Yes, he said, it's a carbon arc torch. Intended for brazing. You're much better off with the Oxy Acetylene though. Time passed until one day, as there were some of the rods with it - the copper coloured rods - I decided to see how it might work. You obviously stick a rod in each holder like this:

and control the arc distance by sliding the black knob on the handle back and forwards. So I connected the leads to the welder outputs and, with the rod tips well apart, switched the welder on. Face shield down and gently slid the tips towards each other. After a bit of fiddling about with the output on the welder I got a good arc. The arc burns the rods back as you go so you have to be continually pushing the black knob forward, very slowly, to maintain the arc, but it's not that difficult to maintain the arc. Ok, lets get some flux and a brazing rod out and have a go on some thin sheet steel. Now it gets more difficult because you're trying to see what you're doing around the flaring arc - which is much more obstructive than a flame - at the same time as controlling the distance between the tips to stop the arc going out while at the same time watching the brazing itself. I found it very difficult and didn't get a good result at all. Next time my friend called by we set the machine up and I showed him what I'd been trying to do. Hmm, he said, can't see you're doing anything wrong, but the result is poor isn't it, the melted rod isn't flowing and adhering to the workpiece as you'd expect. He had a go himself and said, "we don't really teach this in college, but something's definitely wrong here. After our usual cup of tea or maybe cuppaccino? he examined the kit and suddenly said, "Ah, I think I know what the problem is - these rods are gouging rods"! This meant nothing to me, but he explained that gouging rods are used to strike an arc between a workpiece and the rod to erode a groove in the workpiece. I'd never heard of this but he said it might be used to gouge out a faulty weld before then rewelding a better quality of weld into the joint. Take a look at the rod and you'll see it's not a solid rod, it has a carbon core which is designed to maximise it's gouging ability:

it's not designed to sustain an arc in the way we're trying to use it. Maybe you can just about see what he was talking about in the above picture. He said he thought the rods for brazing are likely to be different. Later I bought a couple of the correct rod from Machine Mart - they weren't particularly cheap - and their centres looked kind of "sparkly". They did work much better and I managed to perform a rather rough braze using them. The main problem is the kit itself is so bulky, and of course it's all live when in use, that you can't do much on a vehicle with it. I've never bothered with it again and it just sits in the box as a curiosity.

Of all the things that were in the boxes I'm most pleased with a home made, I guess? stand for the soldering irons:

made from welding wire from the look of it

I like making stuff like this myself but the quality of this wee stand is outstanding (pun intended!) I'd love to meet the chap who made it and be able to tell him I'm taking good care of his tools.

I was also very pleased to find this tin full of tips for the Weller Soldering Irons:

Maybe 10 years ago I bought a cheap soldering iron from one of the discount supermarkets because it was cheap and because it ran on 240 volts so was quicker to set up than the 110 volt stuff with it's big transformer:

Probably uses considerably less "juice" too? However, at 30 watts, I find it's of limited use on vehicles. Also it's doesn't seem to be temperature stabilized so if you leave it switched on for a while without melting any solder with it it tends to get too hot to the detriment of the quality of the soldered joint. The wee crocodile clips are a good idea for holding stuff together while soldering though.