The crank locking tool should have a little hole where the 'pip' locates that is on the pulley so that the locking tool can only go on one way

What i do is rotate the crankshaft with all the covers off, place the crank tool over by hand first and see where you are, then rotate bit by bit slowly until it lines up, place tool over and finger tight the bolts.

The cam tool 'should' go in. Get a mirror and see it the cut out is visible in the camshaft, if not, remove crank locking tool, rotate the crankshaft ONCE and lock back into place with the tool. Then you should see the camshaft cut out and fit tool. If it does not go in nicely then the timing is out slightly. Don't panic, remove belt then rotate camshaft via the pulley bolt slowly until tool fits in.

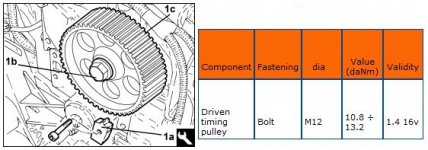

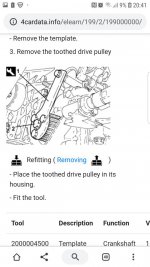

Yes leave cam locking tool in when cracking off pulley, NOTE this will require a pulley holder and big bar as these are very tight! 2 man job, one holds the pulley holder while the other cracks off with a 2 foot breaker bar (reverse way to tighten) And the cam locking tool will not hold this alone. I left the cam locking tool in place and just made sure the pulley did not move whilst un doing

I would not worry about the cylinder pin tool you mention

What i do is rotate the crankshaft with all the covers off, place the crank tool over by hand first and see where you are, then rotate bit by bit slowly until it lines up, place tool over and finger tight the bolts.

The cam tool 'should' go in. Get a mirror and see it the cut out is visible in the camshaft, if not, remove crank locking tool, rotate the crankshaft ONCE and lock back into place with the tool. Then you should see the camshaft cut out and fit tool. If it does not go in nicely then the timing is out slightly. Don't panic, remove belt then rotate camshaft via the pulley bolt slowly until tool fits in.

Yes leave cam locking tool in when cracking off pulley, NOTE this will require a pulley holder and big bar as these are very tight! 2 man job, one holds the pulley holder while the other cracks off with a 2 foot breaker bar (reverse way to tighten) And the cam locking tool will not hold this alone. I left the cam locking tool in place and just made sure the pulley did not move whilst un doing

I would not worry about the cylinder pin tool you mention

Last edited: