- Joined

- Jul 13, 2016

- Messages

- 640

- Points

- 234

Hey guys

Have 1.4 2009 tjet GP. It is due some love as parts are starting to play up. I have a chirpy type / grunchy noise coming from belt area and believe it is the tensioner.

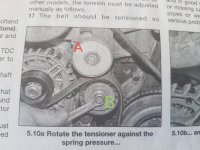

I want to replace it, now to replace it do I (see pic)

1) Remove the hex bolt (A) that is situated in the spring load mechanism I guess it is and simply pull it off

OR

2) Do i remove the bolt (B) that is situated in the pulley part and simply pull that of OR is it a remove both?

Have 1.4 2009 tjet GP. It is due some love as parts are starting to play up. I have a chirpy type / grunchy noise coming from belt area and believe it is the tensioner.

I want to replace it, now to replace it do I (see pic)

1) Remove the hex bolt (A) that is situated in the spring load mechanism I guess it is and simply pull it off

OR

2) Do i remove the bolt (B) that is situated in the pulley part and simply pull that of OR is it a remove both?