I've got 4 of them

Plus a big block of wood to hide behind, and a strong rope to put through the spring while compressing, so it can't fly all over the place. Should be safe enough. Would be nicer to have a hydraulic leg press though. Luckily all I need to do is to compress the new springs. The old struts will be just unbolted from the frame and disposed of.

I'm not sure if it applies to shipping outside the UK but here, if you make a small

donation to Forum funds you can claim an additional discount from S4p. Last time I ordered, as long as you were spending more than £25, shipping was free too. Might be worth exploring that for future reference. I order service parts for our Panda and Punto in one go and always qualify for free shipping Larger orders, like the struts and top mounts, always exceed the amount so qualify. (they have never sent me a wrong or different part to what I ordered.

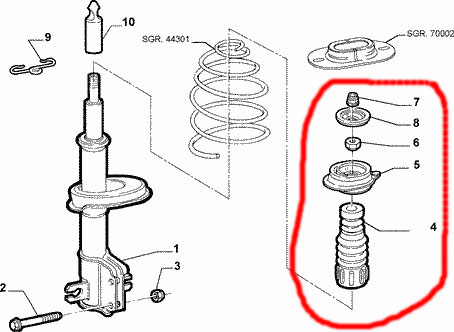

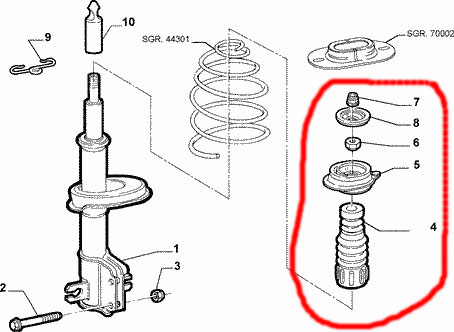

The top mount nut is quite a specialized thing with it's machined "lip". I would guess may only be available from the dealer? Mine were both in absolutely A1 condition - I would have gained nothing by renewing them.

Compressing main suspension springs? always a bit of a high stress activity! I think you are saying you have 4 compressing tools? Is it your intention to use all 4 at the same time on the one spring? If you are that won't work because there is always going to be one which looses contact with the spring as you tighten another so this slack one will then slip around and get in the way. You might do it with 3 spaced equidistantly around the spring. The big thing to achieve when compressing these springs with these types of tool (ie. not the big single leg type with a plate at top and bottom - which are safer) is to avoid introducing a "banana" shaped curve into it which is what will encourage the compressors to slip. You need to have the compressors situated directly opposite each other to achieve this and tighten only a few turns at a time on each compressor to avoid putting too much of a bend into the shape of the spring which will also encourage the tool to slip. As you tighten keep watching all the time for it starting to "banana" and if it shows any tendency to do so then slacken right off and reposition the compressors to avoid it. Using 3 tools will, by the very nature of it, introduce a Banana shape so I wouldn't do it with 3. I've been doing it with 2 for over 50 years now and never had a problem but I always treat them with great respect and concentration. I have never forgotten the story told to us in college (way back in the '60's - happy days) of a spring getting loose in a workshop the instructor had worked in. Apparently it flew across the workshop and knocked over an oxygen cylinder which was waiting to be changed for an empty one in the welding bottle trolley. The valve in the top of the bottle was sheared off as the bottle hit a workbench on the way down and the pressure of the gas turned the bottle into a missile which skidded across the concrete workshop floor and shot out through the doors into the car park. Luckily, he told us, it came to rest without hitting anything, but the noise of the escaping gas was impressively frightening! So I would say. Have confidence. Use 2 compressors positioned precisely opposite each other. Tighten each in turn by just a small amount to avoid the spring bending very much and watch closely for the "banana effect". Most of all, don't keep on tightening if it starts to "banana".

I feel very confident doing this and wouldn't hesitate to undertake another, however there is always the unexpected. I did quite a big post recently when I did Becky's struts, springs, top mounts etc and someone then posted to the effect "what about if the old spring breaks when being compressed"? All I can say is it's never happened to me and I've done quite a fair few over the years. I don't think, using these simpler, cheaper, types of compressing tools that you can ever be 100% safe, but that's life isn't it? you just have to balance what you are prepared to risk and take reasonable precautions. Big blocks of wood and pieces of rope? fair enough but prevention is always better than anything else.