torniojaws

New member

- Joined

- May 4, 2019

- Messages

- 137

- Points

- 40

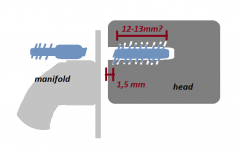

I cleaned the maniverter of my 2008 1.2 65 Grande Punto, and while reinstalling the maniverter, one of the engine block studs (where the gasket is fitted) snapped just before reaching the target torque (24 Nm, ~18 ft-lb). I tightened them in a X pattern, first to finger-tight, then ratchet resistance, and finally to torque.

They appear to be a part of the engine block - is there some way to replace them? At least they don't seem removable, unlike the headless bolts that you attach after fitting the maniverter in place. It's the one in the top left.

The maniverter is still attached by 7 of the 8 nuts and bolts, and no flames appear so it's not yet critical, but it's something I'd like to get sorted.

so it's not yet critical, but it's something I'd like to get sorted.

Thanks!

They appear to be a part of the engine block - is there some way to replace them? At least they don't seem removable, unlike the headless bolts that you attach after fitting the maniverter in place. It's the one in the top left.

The maniverter is still attached by 7 of the 8 nuts and bolts, and no flames appear

Thanks!