Hello everyone.

I am seeking some advice for a problem i have with my Grande punto T-jet (stock VL37 turbo).

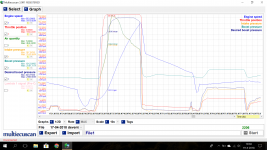

My car has been chiptuned to around 140bhp, 250nm. Lately i feel like when i do a pull (put my foot down) that the car is holding back somehow. So as i have multiecuscan i connected the interface to the car and started a log to see what was going on (This log was made during a 30km trip with the a/c off, i added it to my post). Now when you take a look at the data you can see that the boost pressure hits the desired boost but after around 3200-3400rpm it drops off. My prime suspect after reading alot on the internet is the turbo actuator spring which could be too weak for the increased boost.

I am wondering whether i can check via multiecuscan if it’s the ecu opening the actuator after 3400rpm or if its the actuator spring that is letting me down. The only parameter I think shows this is the “turbo actuator command” parameter which is described in MES as “This is the duty cycle (in %) of the turbo actuator valve control.”. I did a 2nd gear pull with this (and a lot of other) parameter(s) selected. However I’m not sure how to interpret the data (I also added this file to my post).

Are there any people with knowledge of MES that can help me with this issue?

Greetings, Luuk

(I added the files within a zip. file as CSV files so they can be easily imported and viewed within MES)

I am seeking some advice for a problem i have with my Grande punto T-jet (stock VL37 turbo).

My car has been chiptuned to around 140bhp, 250nm. Lately i feel like when i do a pull (put my foot down) that the car is holding back somehow. So as i have multiecuscan i connected the interface to the car and started a log to see what was going on (This log was made during a 30km trip with the a/c off, i added it to my post). Now when you take a look at the data you can see that the boost pressure hits the desired boost but after around 3200-3400rpm it drops off. My prime suspect after reading alot on the internet is the turbo actuator spring which could be too weak for the increased boost.

I am wondering whether i can check via multiecuscan if it’s the ecu opening the actuator after 3400rpm or if its the actuator spring that is letting me down. The only parameter I think shows this is the “turbo actuator command” parameter which is described in MES as “This is the duty cycle (in %) of the turbo actuator valve control.”. I did a 2nd gear pull with this (and a lot of other) parameter(s) selected. However I’m not sure how to interpret the data (I also added this file to my post).

Are there any people with knowledge of MES that can help me with this issue?

Greetings, Luuk

(I added the files within a zip. file as CSV files so they can be easily imported and viewed within MES)