This time I can't agree with Digger ... Those bolts are actually fastening safety related stuff !

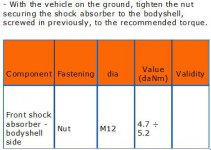

Tightening torque is not there just for fun, the goal is to stretch the bolt a certain amount so its internal tension can still increase/decrease without getting lose nor breaking under normal usage.

Too tight: the bolt can reach its elasticity limit and might break if stressed

Not enough tight: the bold could get lose, assembled parts get play, get worn etc.

Personaly I even torque my wheels bolts, but I must admit I don't use the torque wrench on every nut I see when doing general mechanic ;-)

Regards, Bernie