umanemo

Member

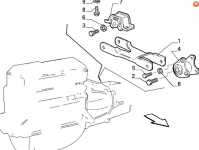

I began this conversation on an older thread but there have been some discoveries to date. What I have written below is the last update. I have identified the R/L side upper brackets issue. (motor-mounts) But there is a third mount at the rear bottom of the transmission that I had thought I had addressed but now I have found out that there are two rubber bearings to the rear mount. (#4 in the ePer diagram attached)

Does anyone have experience with this end of the lower rear mount failing? Does it cause the issues that I have been chasing?

Any heads up is appreciated! Thanks!

[Last Post from Previous thread]

Back to the beginning again.

Some kilometers back I posted the dilemma of having this persistent vibration and thought it could be the gearbox. I found a stellar gearbox rebuilder in NL that invited me to let him have a look at my issues. He is a large worldwide distributor of gearboxes and had thousands of rebuilt gearboxes on the shelves and ongoing refurbishing in the shop by what looked like very skilled technicians. Schoones Transmissies BV.

The owner gave my Motorhome a run around the industrial estate and then out onto the motorway and really put it through a thorough test. His judgment was that these transmissions with the stamp 20KM57 are the most heavy-duty and reliable FIAT has ever produced. He also said there were no tranny issues - even after 335,000km! and that I shouldn't expect any for the life of the vehicle. He also refused to take any money from me, there was nothing wrong with my trans.

So back to square one with the vibration issue. Having just replaced just about everything from the CV shafts to the clutch, all 3 engine mounts I am still stumped. Given that everything under there appears tight, I have just kept my acceleration very conservative and keep the torque just below when the vibration begins to appear. Take off at first gear, and second gear if I step into it. Third gear can show the vibration but only if climbing a hill.

This all vaguely seems to have started with the replacement of the left side motor mount (bearing) so I am going to replace it again. But I do wonder if the LH and RH mounts are exactly the same part? The FIAT part number is 1307907080, but the extensions are RH 1827.19 and LH 1827.17 those numbers differ. IF THEY ARE DIFFERENT COULD THE PROBLEM BE THAT I HAVE A RH WHERE THERE SHOULD BE A LH? Inquiring minds want to know before I order another part.

If anyone has any suggestion of the origin of these symptoms or the answer to if these are truly different parts in configuration or manufacture please let me know.

As always thanks for your invaluable advice and input!

4/3/2000 FIAT Ducato 18Q - 2.8 i.d.TD

8140.43 (Direct Injection)

122 PS (90kW;120 hp) @ 3,600 rpm

5 Speed

VIN: ZFA23000005887229

Engine: 3050633

Chassis: 05887229

MVS (SINCOM): 232.330.1.0

Does anyone have experience with this end of the lower rear mount failing? Does it cause the issues that I have been chasing?

Any heads up is appreciated! Thanks!

[Last Post from Previous thread]

Back to the beginning again.

Some kilometers back I posted the dilemma of having this persistent vibration and thought it could be the gearbox. I found a stellar gearbox rebuilder in NL that invited me to let him have a look at my issues. He is a large worldwide distributor of gearboxes and had thousands of rebuilt gearboxes on the shelves and ongoing refurbishing in the shop by what looked like very skilled technicians. Schoones Transmissies BV.

The owner gave my Motorhome a run around the industrial estate and then out onto the motorway and really put it through a thorough test. His judgment was that these transmissions with the stamp 20KM57 are the most heavy-duty and reliable FIAT has ever produced. He also said there were no tranny issues - even after 335,000km! and that I shouldn't expect any for the life of the vehicle. He also refused to take any money from me, there was nothing wrong with my trans.

So back to square one with the vibration issue. Having just replaced just about everything from the CV shafts to the clutch, all 3 engine mounts I am still stumped. Given that everything under there appears tight, I have just kept my acceleration very conservative and keep the torque just below when the vibration begins to appear. Take off at first gear, and second gear if I step into it. Third gear can show the vibration but only if climbing a hill.

This all vaguely seems to have started with the replacement of the left side motor mount (bearing) so I am going to replace it again. But I do wonder if the LH and RH mounts are exactly the same part? The FIAT part number is 1307907080, but the extensions are RH 1827.19 and LH 1827.17 those numbers differ. IF THEY ARE DIFFERENT COULD THE PROBLEM BE THAT I HAVE A RH WHERE THERE SHOULD BE A LH? Inquiring minds want to know before I order another part.

If anyone has any suggestion of the origin of these symptoms or the answer to if these are truly different parts in configuration or manufacture please let me know.

As always thanks for your invaluable advice and input!

4/3/2000 FIAT Ducato 18Q - 2.8 i.d.TD

8140.43 (Direct Injection)

122 PS (90kW;120 hp) @ 3,600 rpm

5 Speed

VIN: ZFA23000005887229

Engine: 3050633

Chassis: 05887229

MVS (SINCOM): 232.330.1.0