Hi again!

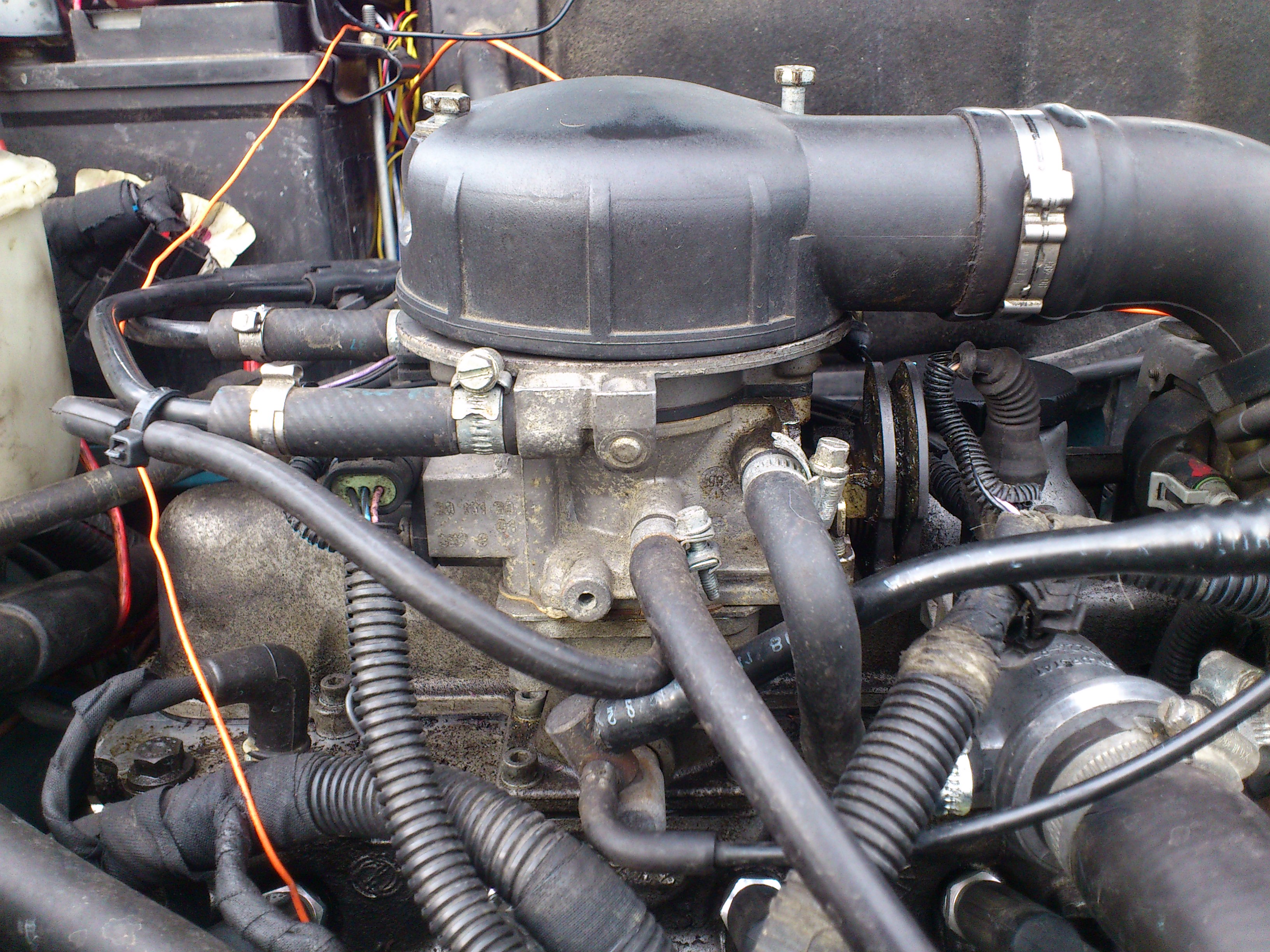

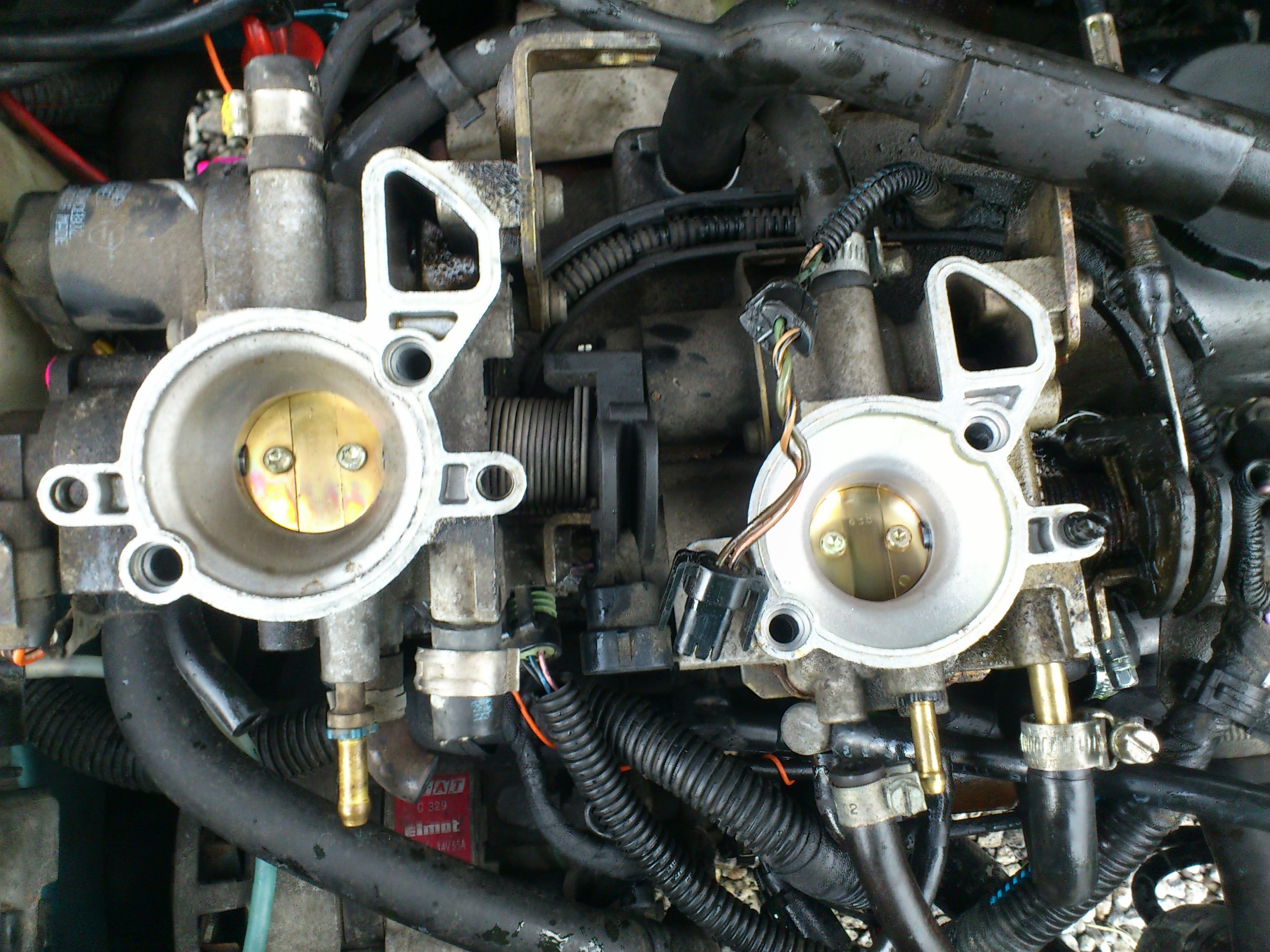

So the next thing im looking to do with my cinq is put a 32mm throttle body in it, im hoping this will increase power and torque a little on my 899!

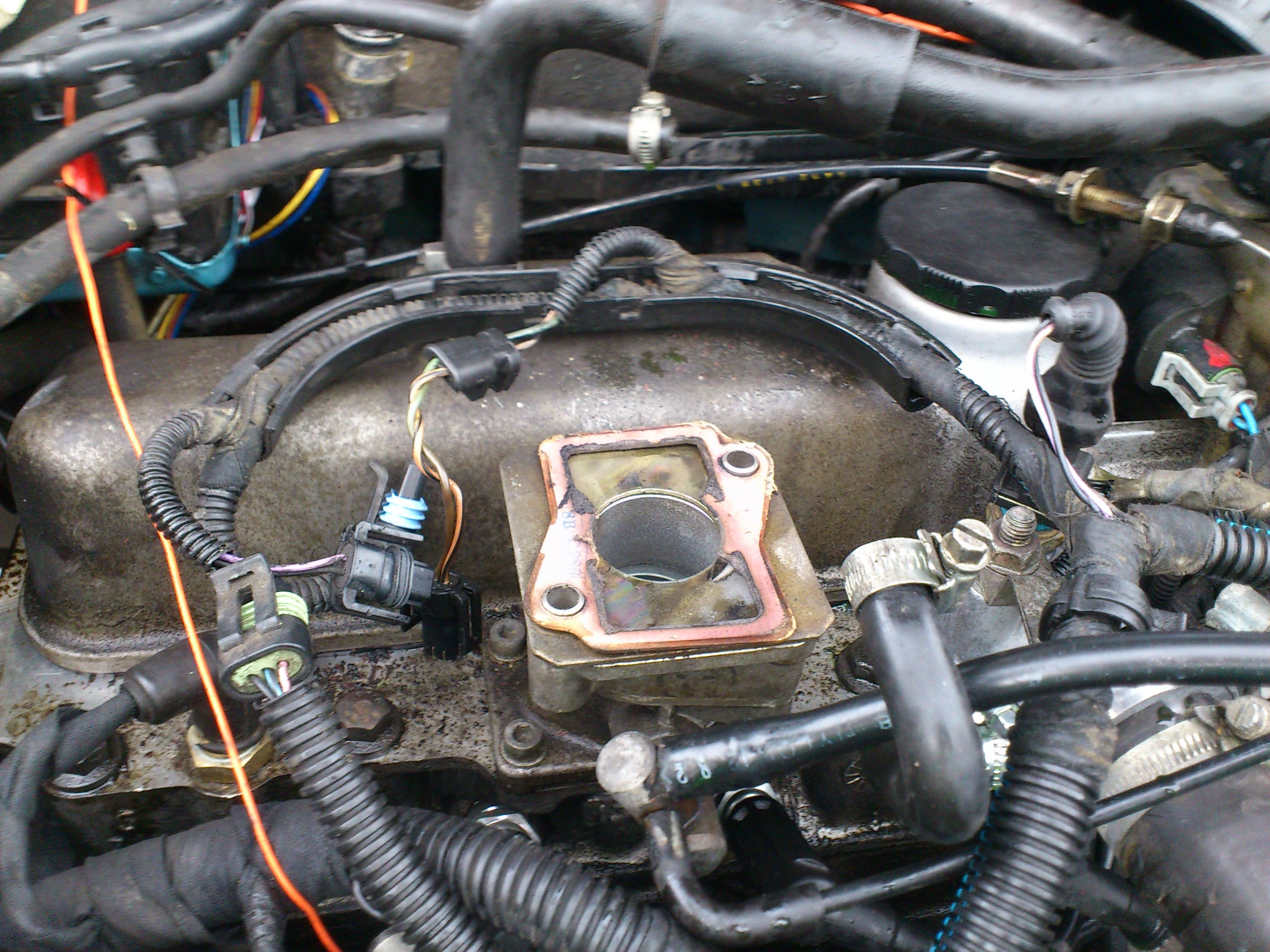

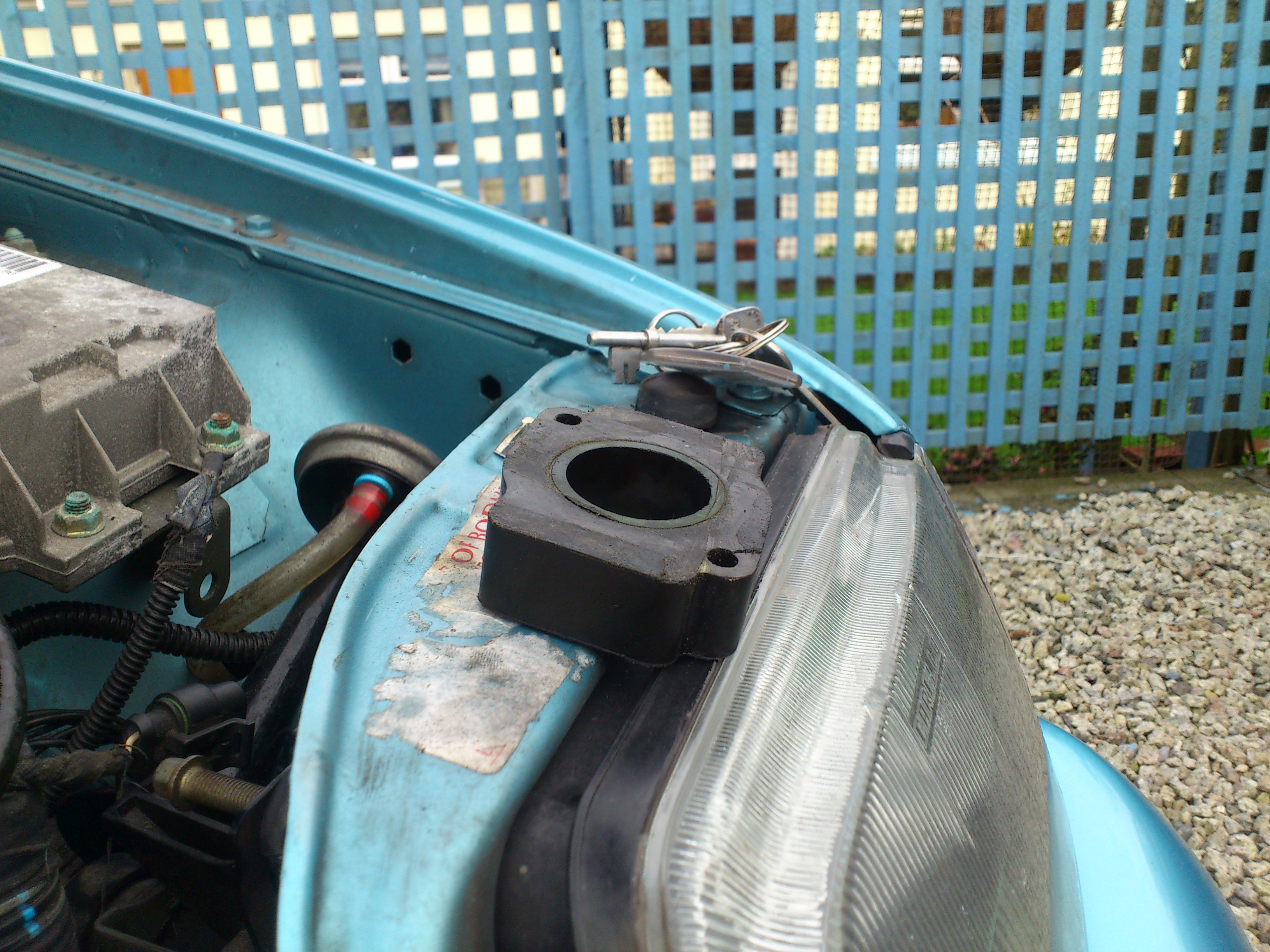

I have sourced a tb from my breakers yard however i have not purchased it yet as it doesnt have the spacer, and i cant find one on ebay or on the forum!

Can anyone help me out here?

I will be posting pictures of my progress to help anyone else who is doing this

Thanks!

Chris

So the next thing im looking to do with my cinq is put a 32mm throttle body in it, im hoping this will increase power and torque a little on my 899!

I have sourced a tb from my breakers yard however i have not purchased it yet as it doesnt have the spacer, and i cant find one on ebay or on the forum!

Can anyone help me out here?

I will be posting pictures of my progress to help anyone else who is doing this

Thanks!

Chris